Device and method used for rigid mold bulging and hydraulic bulging tests of plates

A hydraulic bulging and rigid technology, which is applied in the field of plate rigid die bulging and hydraulic bulging test devices, can solve the problems of inconvenient use of test molds and increased test costs, and achieve rich use functions, simple loading and unloading, and increased The effect of interchangeability of molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

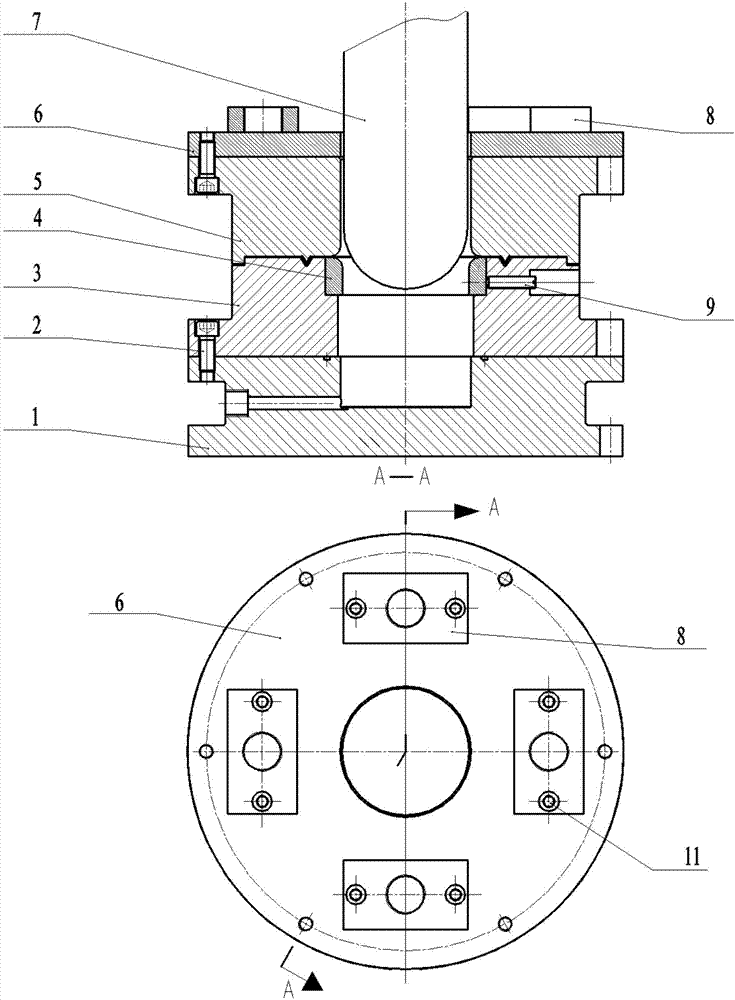

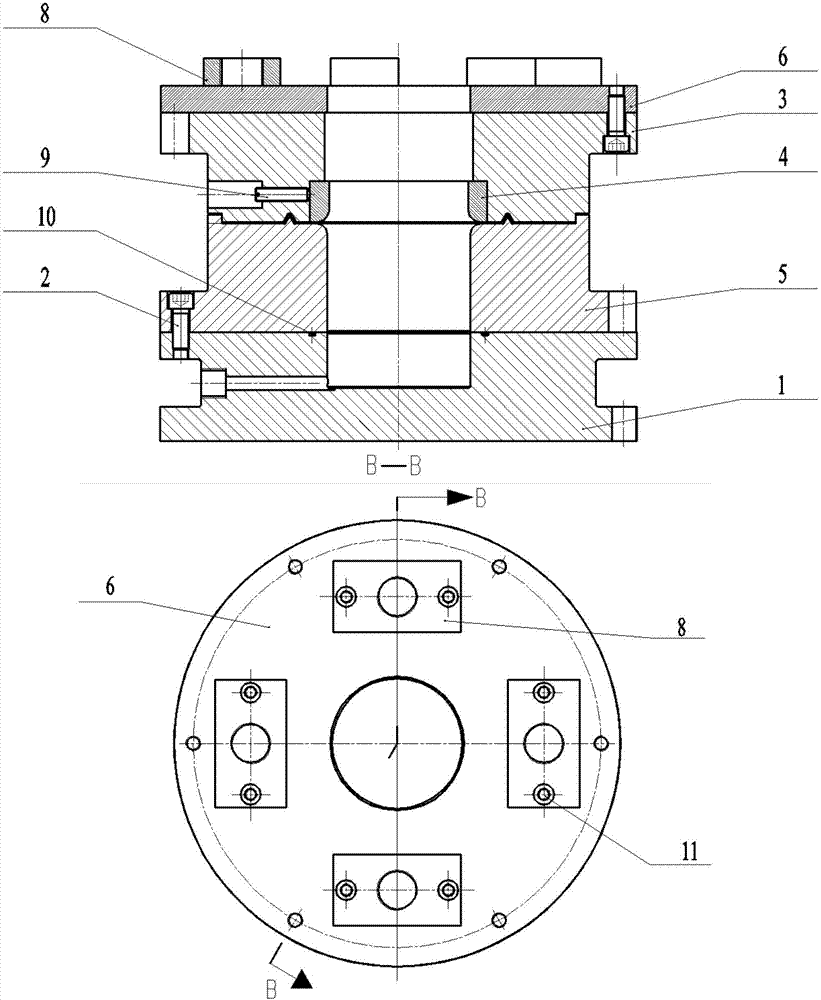

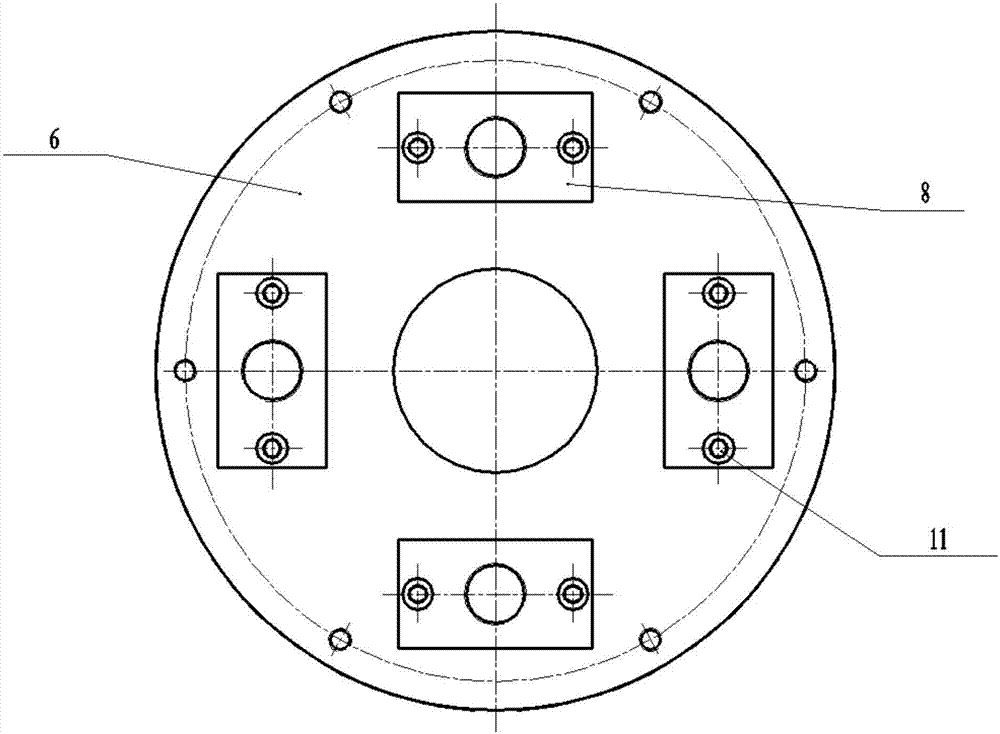

[0041] like figure 1 , figure 2 and Figure 5 , a device of the present invention that can be used for plate rigid die bulging and hydraulic bulging tests includes: liquid chamber 1, hexagon socket head cap screw 2, die base 3, die insert 4, blank holder 5, press Side transfer block 6, hemispherical head bulging punch 7, edge holder 8, slotted taper end set screw 9, O-shaped rubber sealing ring 10, hexagon socket head cap screw 11. According to different test purposes, the combination mold can be used for rigid mold bulging test after assembling the mold in different ways ( figure 1 shown) and hydraulic bulging test ( figure 2 shown).

[0042] like figure 1 , when the combined mold is used for the rigid mold bulging test, it consists of a liquid chamber 1, a die base 3, a die insert 4, a slotted taper end set screw 9, a blank holder ring 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com