Remote numerical control multipurpose uphill and downhill trolley

A technology of uphill and downhill and trolley, which is applied in the direction of electrical program control, sequence/logic controller program control, motor vehicles, etc. It can solve the problems of single function, large number of trolleys, and inability to attach hoists or fixtures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

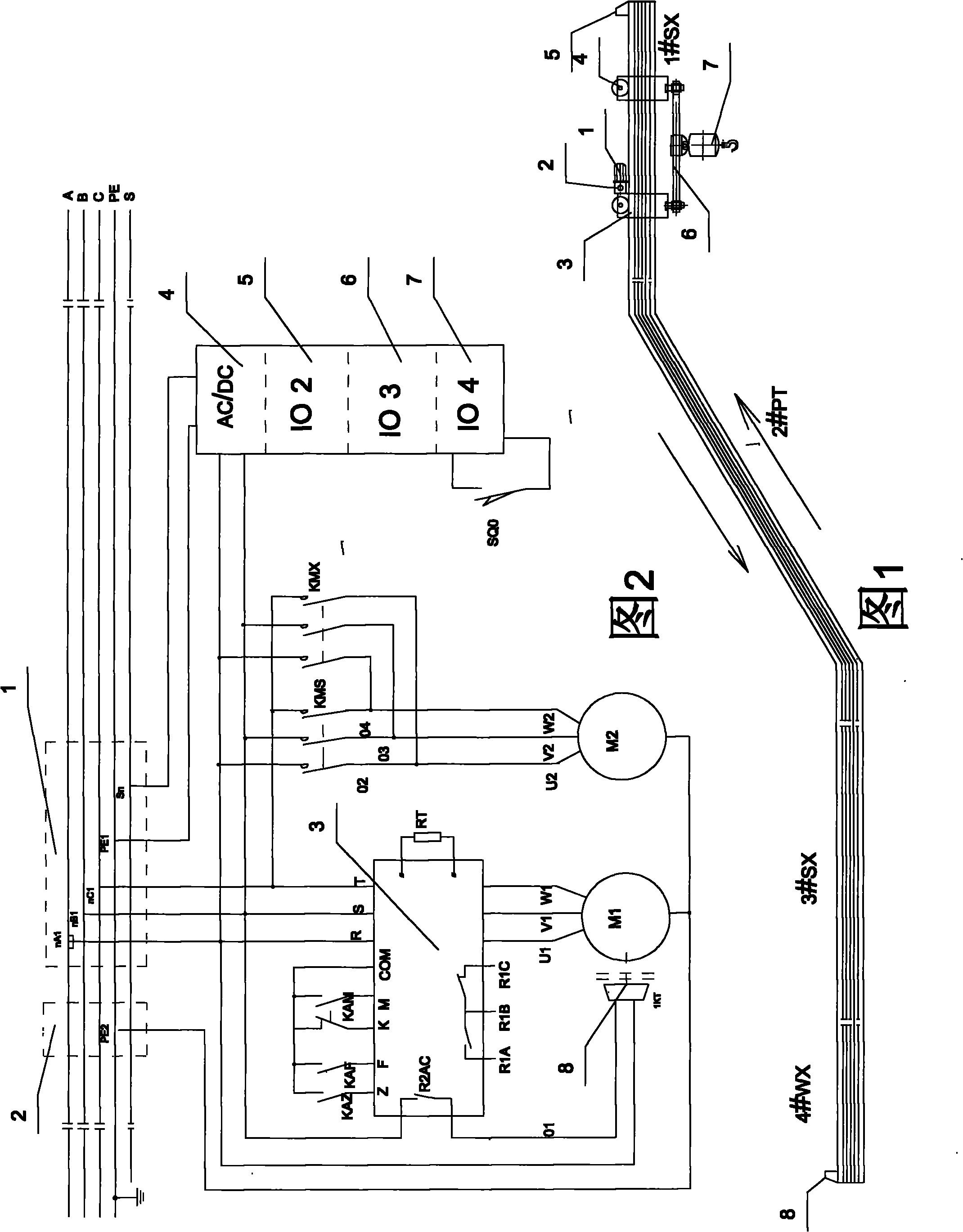

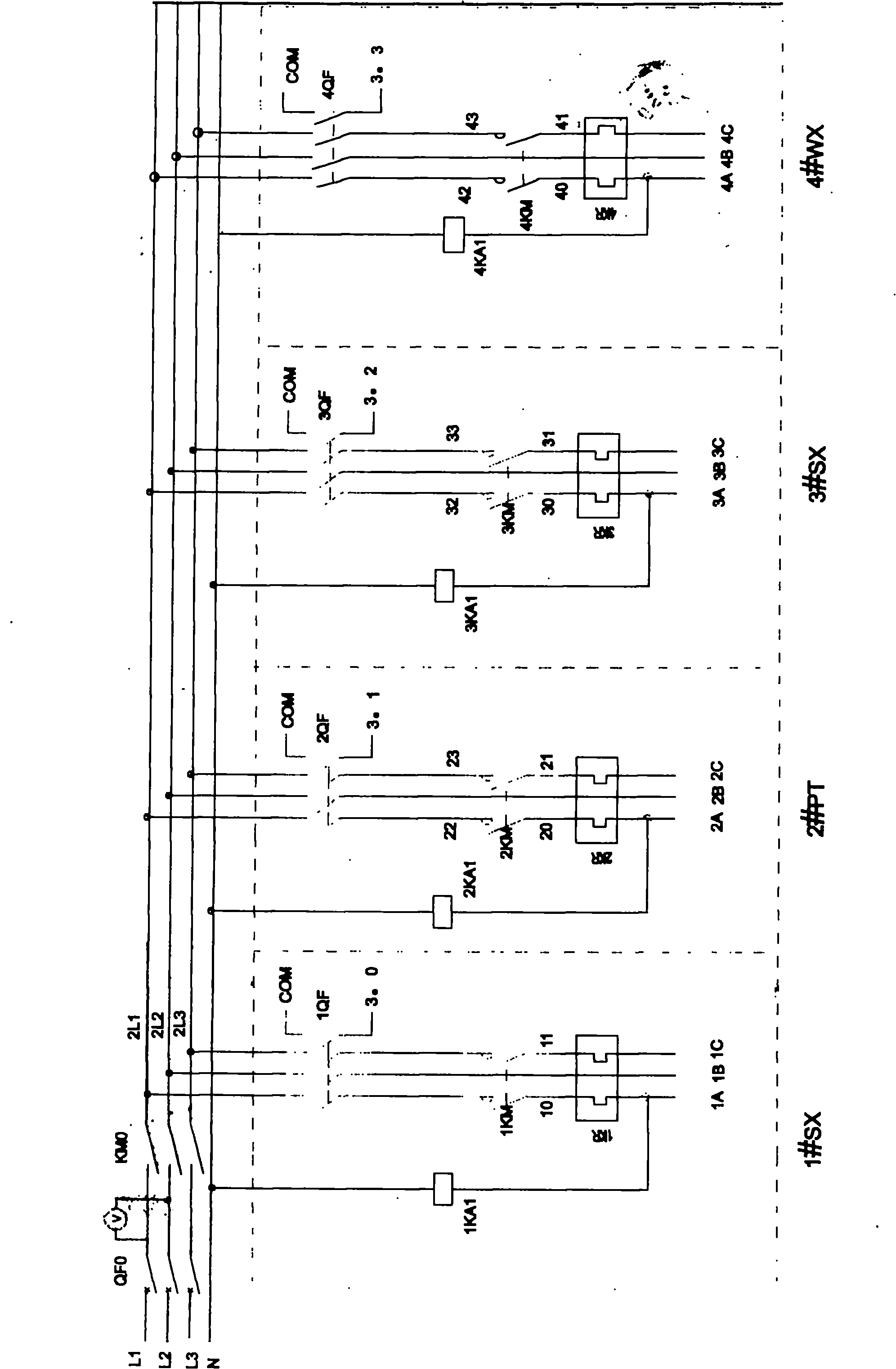

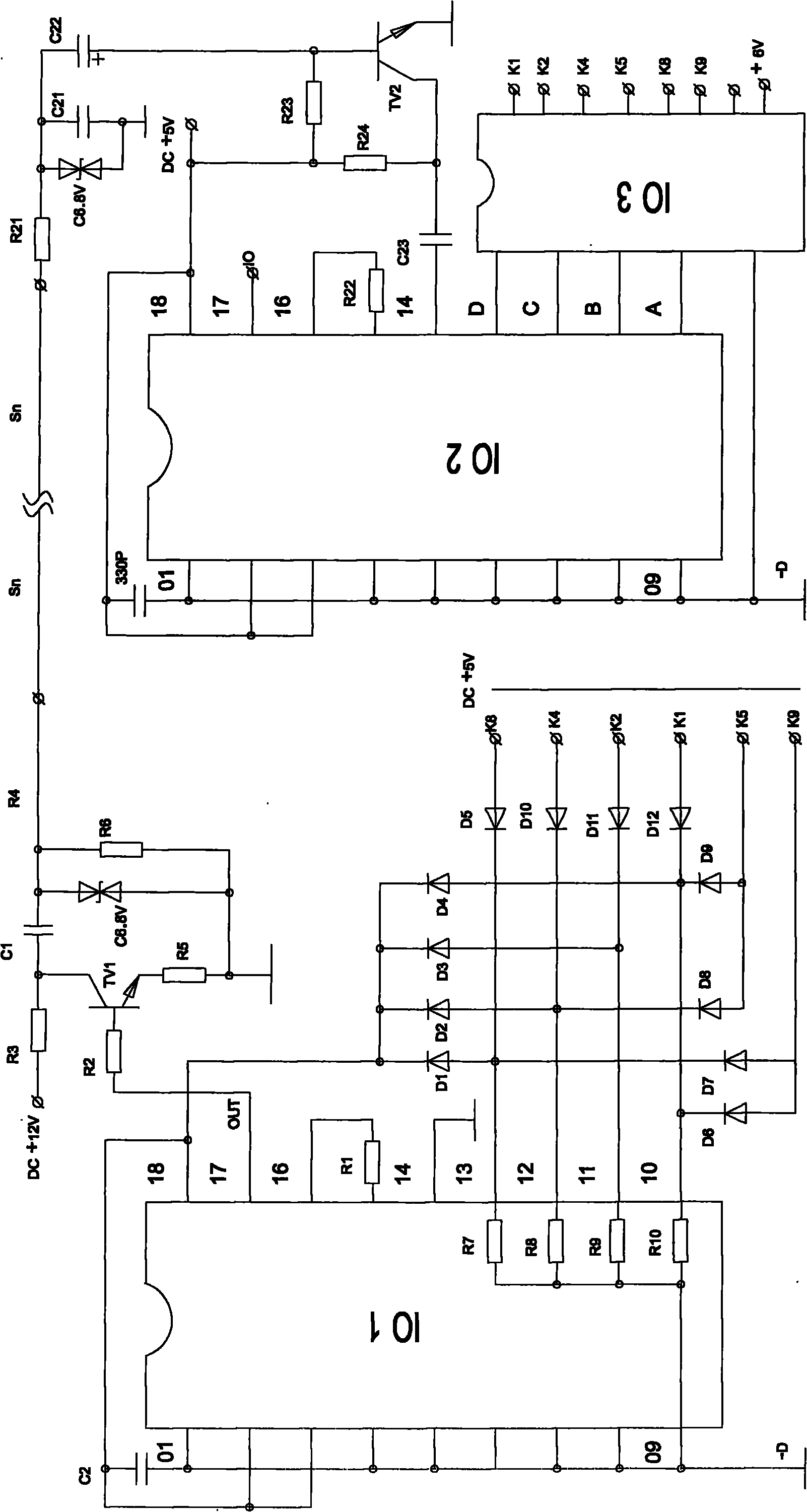

[0021] For specific embodiments of the present invention see figure 1, 1#SX and 3#SX are the loading and unloading stations; 2#PT is the up and down ramp; 4#WX is the maintenance station. Among them, 1 is the traveling motor of the trolley; 2 is the reducer; 3 is the main car of the trolley; 4 is the auxiliary car of the trolley; 5 and 8 are limit safety blocks; The electric hoist that puts material; 9, five slide contact lines that are contained in track side. In addition, there is also a set of gear electromagnetic brake mechanism on the frame, a set of electric control box with the car, a power step-down and rectification device in the box, a control signal decoding and feedback signal encoding integrated circuit board, and a frequency converter , 5 AC contactors, each of which is connected to the main control cabinet through a brush-sliding line-cable. There are 5 sets of AC contactors installed in the main control cabinet on the ground; and a set of four-module PLC, fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com