Drilling bit assembly, drilling device and drilling method

A drill bit assembly, drilling device technology, applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc., can solve problems such as inability to achieve drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

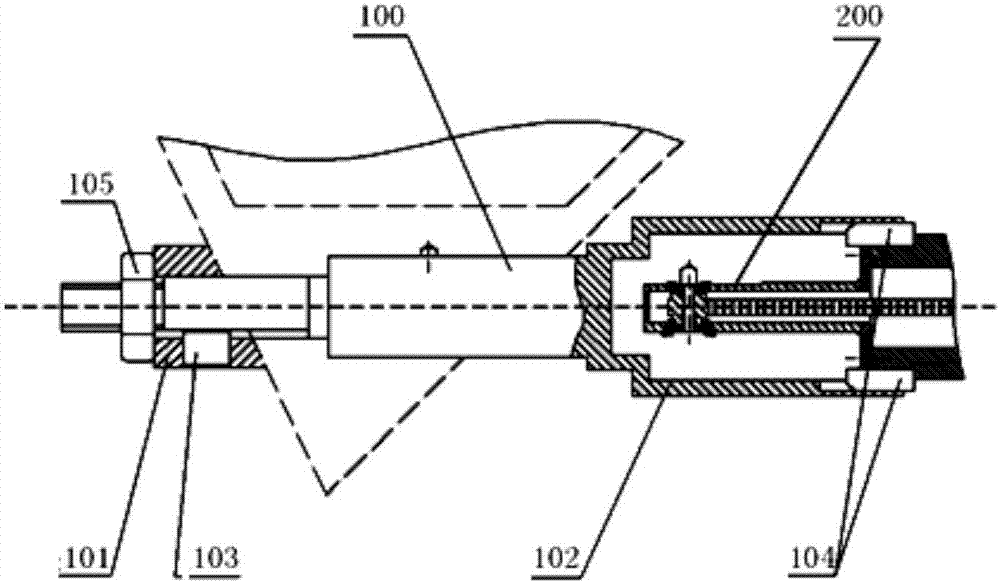

[0075] In this embodiment, the punching device provided by the device embodiment is used to punch holes in the existing holes of the workpiece shell, such as Figure 7 As shown, the workpiece shell is a hollow rotary body structure, the bottom diameter is Φ400-Φ800mm, and the height is 1000-1400mm. The shell is a metal and composite material suit shell. The existing hole is close to one end of the workpiece, which is a stepped through hole. The axis and the horizontal plane The included angle is 55°, the large diameter of the existing hole is 25mm, and the small diameter is 15mm. A vertical blind hole with a depth of 2mm and a diameter of Φ5.5mm is machined at point P of the large diameter section. The drilling methods include:

[0076] Fix the workpiece on the fixed plate 401, adjust the elevator 402 to turn the fixed plate 401 55°, so that the existing holes are placed horizontally;

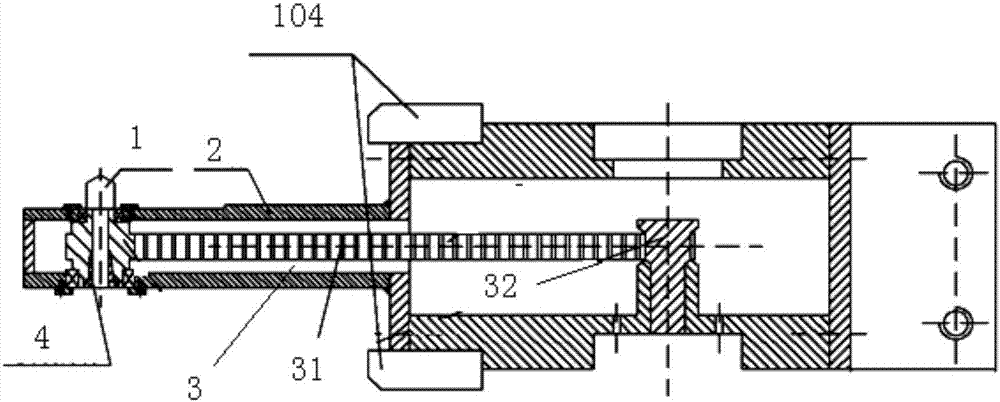

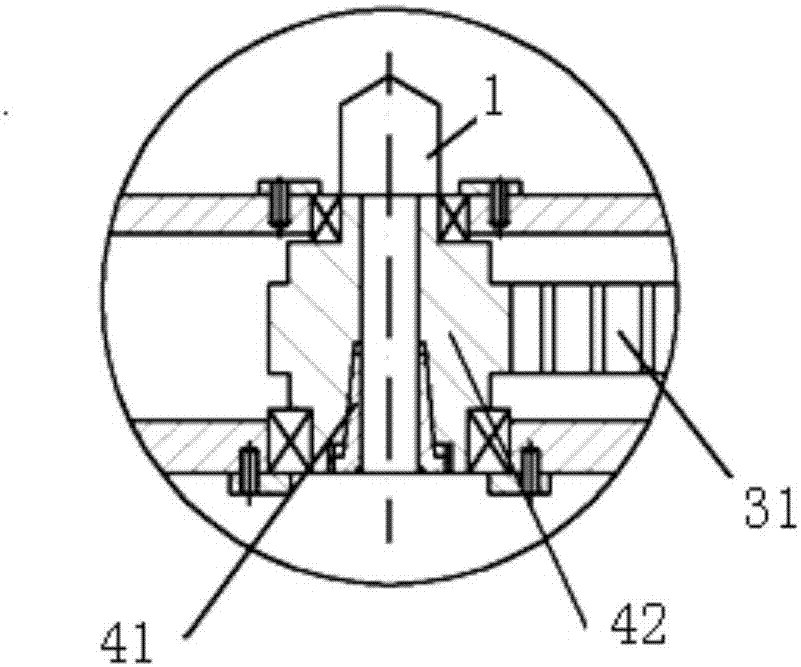

[0077] like image 3 As shown, the positioning block 101 and the positioning cylinder 102 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com