No-load energy-saving device for electric welding machine

An energy-saving device and electric welding machine technology, which is applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of high failure rate, high manufacturing cost, inconvenient operation, etc., achieve reliable no-load energy saving, improve life, and reduce arc The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

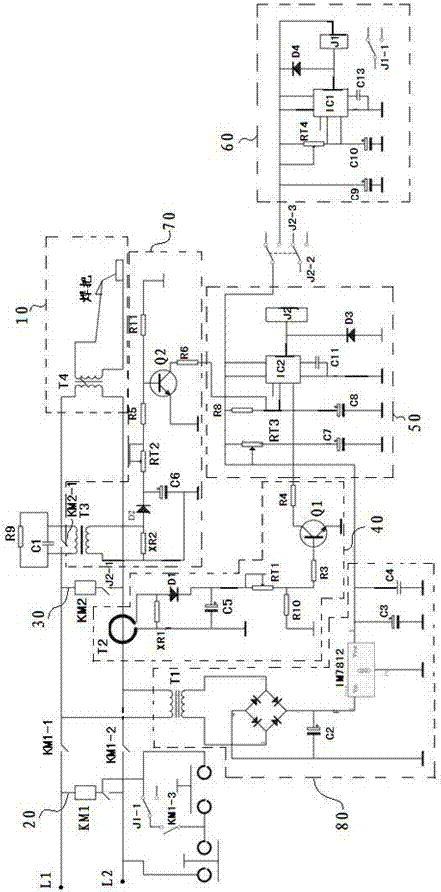

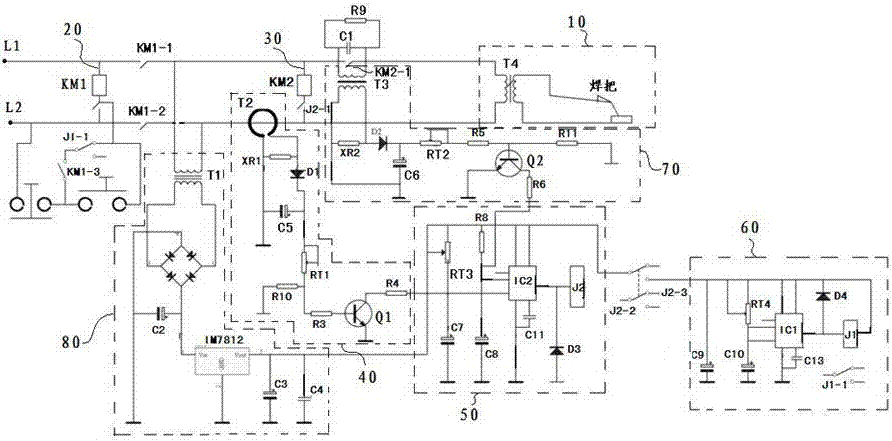

[0012] Such as figure 1 In one embodiment of the no-load energy-saving device for an electric welding machine shown in the present invention, the no-load energy-saving device for an electric welding machine includes that the primary coil of the transformer T4 of the electric welding machine 10 is connected to the power terminals L1 and L2, and the two power terminals L1 , L2 is also connected with the first control branch 20 composed of the pull-in coil of the first contactor KM1 and the normally closed contact J1-1 of the first relay J1, and the first control branch is also connected in parallel with a free The load energy-saving control branch 30, the no-load energy-saving control branch 30 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com