Wear-resistant and slip-resistant rubber sole formula and preparation method thereof

A rubber sole, anti-slip technology, applied in soles, footwear, applications, etc., can solve problems such as difficult to balance both, downsizing, training injuries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

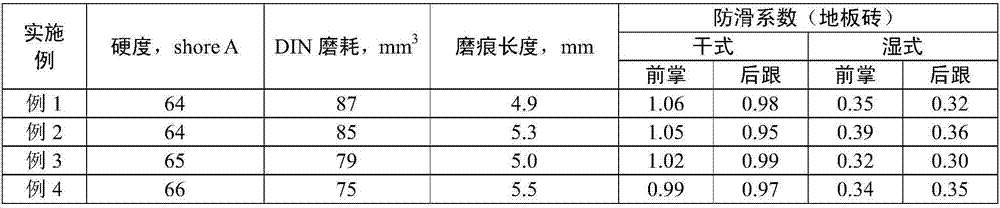

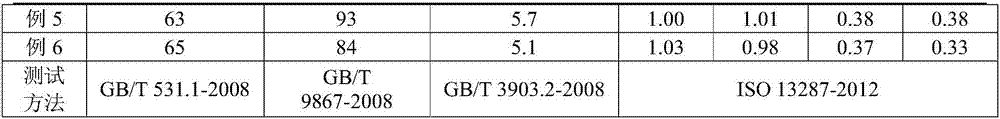

Examples

Embodiment

[0033] The formula in Table 1 was used to prepare the rubber outsole according to the following process.

[0034] Process: 1) Rubber mixing: use a rubber internal mixer and an open mixer for mixing. The order of feeding is: raw rubber, tackifier, anti-aging agent, accelerator, activator, reinforcing filler, vulcanizing agent (Si-69). Material cooling. Control the roller temperature of the open mill below 55°C, add sulfur at this time, thin pass 3 to 5 times, and then release the sheet for use.

[0035] 2) Compression molding: Put the mixed rubber after kneading into a shoe sole mold for molding and vulcanization. The vulcanization conditions are: pressure 50-60MPa, temperature 160-165°C, time 5-6min.

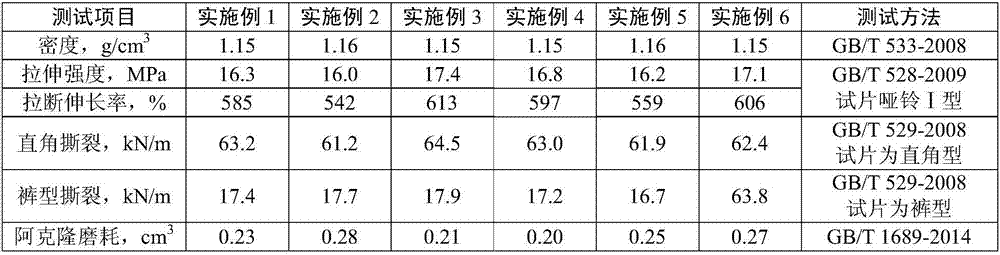

[0036] Table 1 rubber outsole formula

[0037] raw material

Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

50

50

60

55

45

55

Butadiene rubber

30

25

30

30

30

25

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com