Thermoplastic elastomer composition and its preparation method and application

A thermoplastic elastomer and composition technology, which is applied in the field of polymer modified materials and their production and processing, can solve the problem of wet-slip resistance, wear resistance, poor weather resistance, and single-material flooring can not meet the impact absorption performance and ball resilience performance at the same time. and other problems, to achieve the effects of excellent weather resistance, improved comfort and safety, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

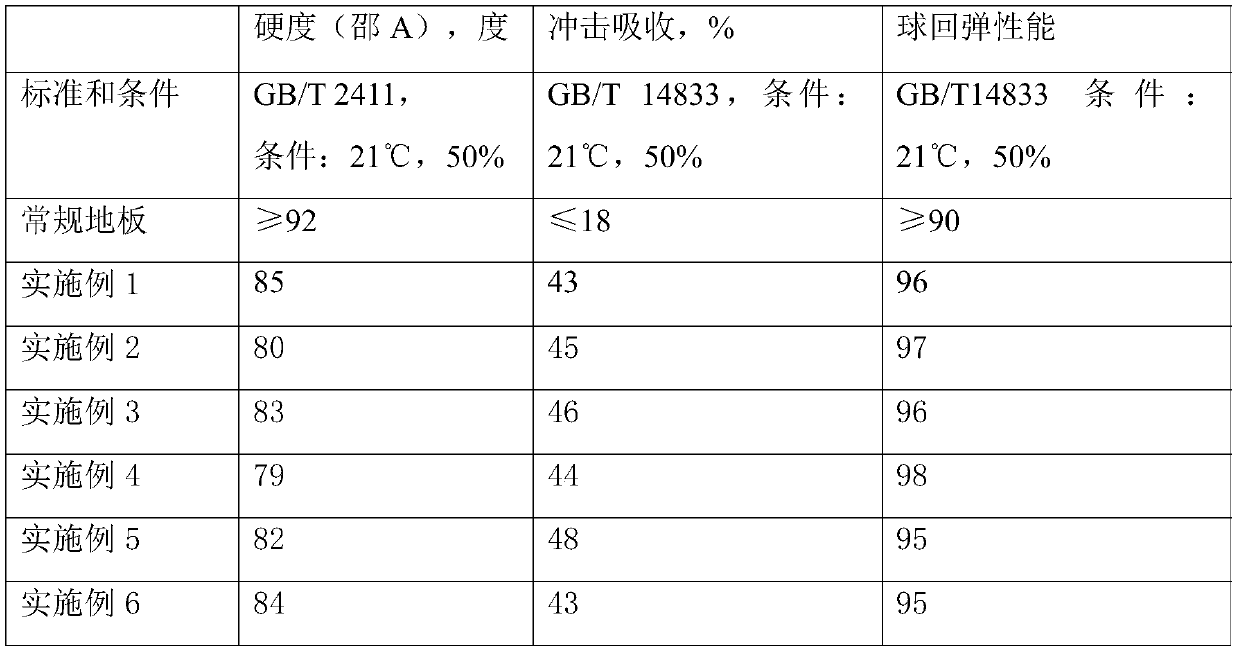

Examples

Embodiment 1

[0037] The thermoplastic elastomer composition is composed of the following components by weight: 75 parts of SEEPS, 65 parts of ethylene-octene block copolymerized olefins, 87 parts of paraffin oil, 102 parts of maleic anhydride grafted butadiene, 132 parts of maleic anhydride Anhydride grafted polypropylene, 60 parts of high styrene rubber powder, 64 parts of nitrile rubber powder, 54 parts of silicone powder, 33 parts of calcium carbonate, 50 parts of PP granules, and weighed 33 parts of DCP masterbatch and 25 parts of TMPTMA.

[0038] The preparation method is as follows: under the condition of 80°C, fully stir 75 parts by weight of SEEPS until it is fluffy without agglomeration, add 87 parts of paraffin oil and stir to make oil-extended rubber; Parts of ethylene-octene block copolymerized olefin, 102 parts of maleic anhydride grafted butadiene, 132 parts of maleic anhydride grafted polypropylene, 60 parts of high benzene rubber powder, 64 parts of nitrile rubber powder, 54...

Embodiment 2

[0042] The thermoplastic elastomer composition is composed of the following components by weight: mainly composed of the following components by weight: 85 parts of SEPS, 90 parts of ethylene-octene block copolymerized olefin, 105 parts of paraffin oil, 100 parts of maleic anhydride Grafted butadiene, 78 parts of maleic anhydride grafted polypropylene, 85 parts of high styrene rubber powder, 90 parts of nitrile rubber powder, 65 parts of silicone powder, 34 parts of calcium carbonate, 50 parts of PP particles, and weighed 28 parts Parts of DCP masterbatch, 20 parts of TMPTMA.

[0043] Its preparation method is as follows: under the condition of 80°C, fully stir 85 parts by weight of SEPS until it is fluffy without agglomeration, add 105 parts of paraffin oil and stir to make oil-extended rubber; Parts of ethylene-octene block copolymerized olefin, 100 parts of maleic anhydride grafted butadiene, 78 parts of maleic anhydride grafted polypropylene, 85 parts of high benzene rubbe...

Embodiment 3

[0047] The thermoplastic elastomer composition is composed of the following components by weight: mainly composed of the following components by weight: 120 parts of SEEPS, 85 parts of ethylene-octene block copolymerized olefins, 150 parts of paraffin oil, 100 parts of maleic anhydride Grafted butadiene, 100 parts of maleic anhydride grafted polypropylene, 60 parts of high styrene rubber powder, 60 parts of nitrile rubber powder, 56 parts of silicone powder, 58 parts of calcium carbonate, 50 parts of PP particles, and weighed 38 parts Parts of DCP masterbatch, 20 parts of TMPTMA.

[0048] The preparation method is as follows: under the condition of 80°C, fully stir 120 parts by weight of SEEPS until it is fluffy and non-caking, add 150 parts of paraffin oil and stir to make an oil-extended rubber compound, and then mix with 85 parts by weight of SEEPS Parts of ethylene-octene block copolymerized olefin, 100 parts of maleic anhydride grafted butadiene, 100 parts of maleic anhydri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com