A bending node, curved continuous steel truss bridge and its design method

A technology of steel truss bridges and continuous curves, applied in truss bridges, bridges, bridge forms, etc., can solve the problems of inability to adopt steel truss structures and limit the application range of steel trusses, and achieve simple structure, high-efficiency design and Create and create convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

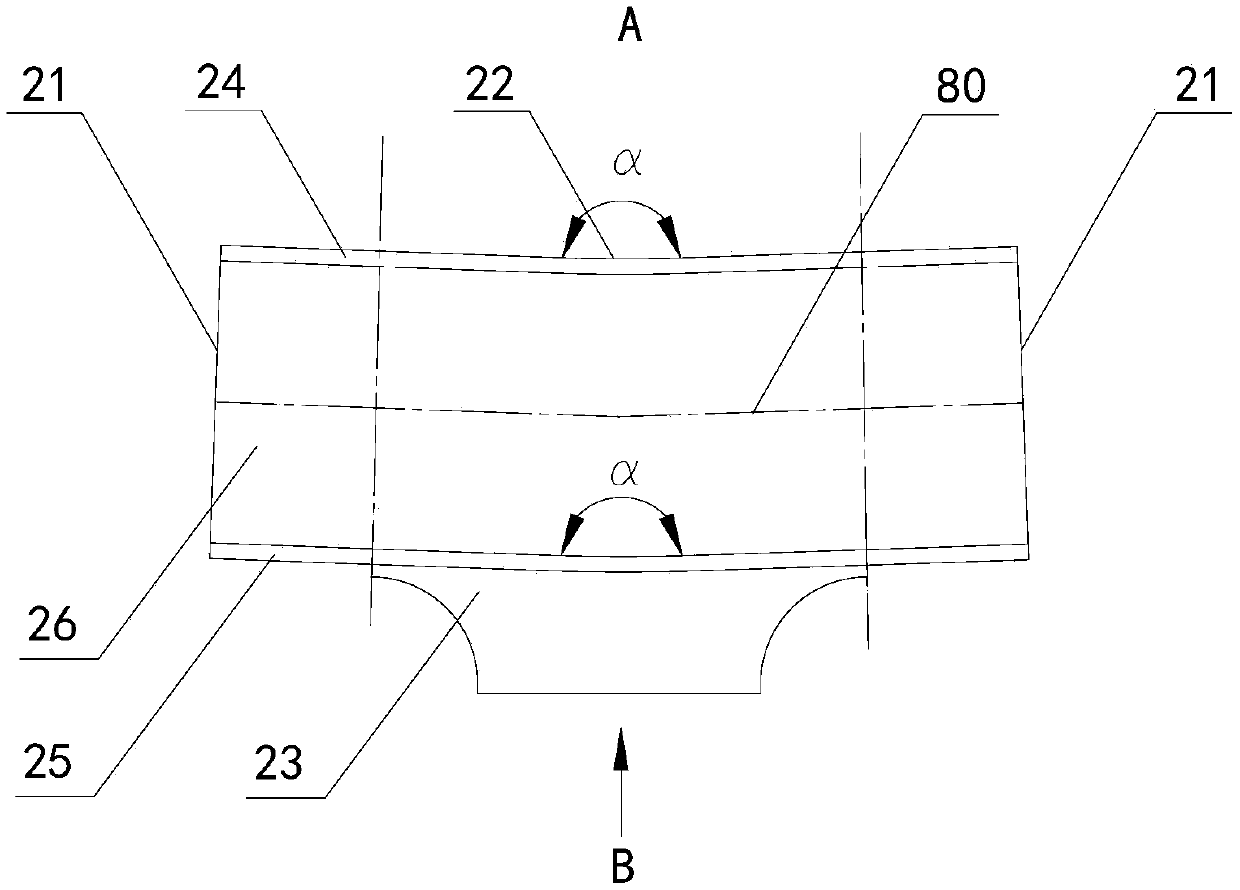

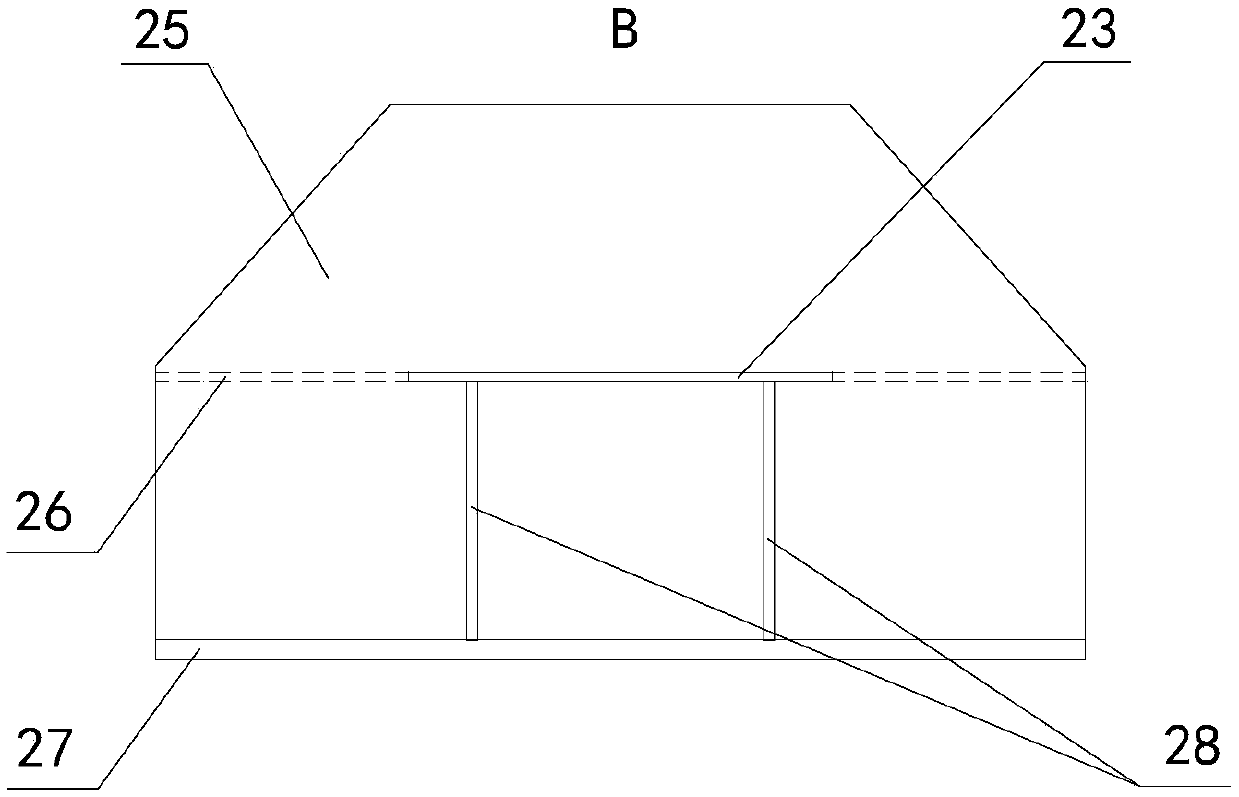

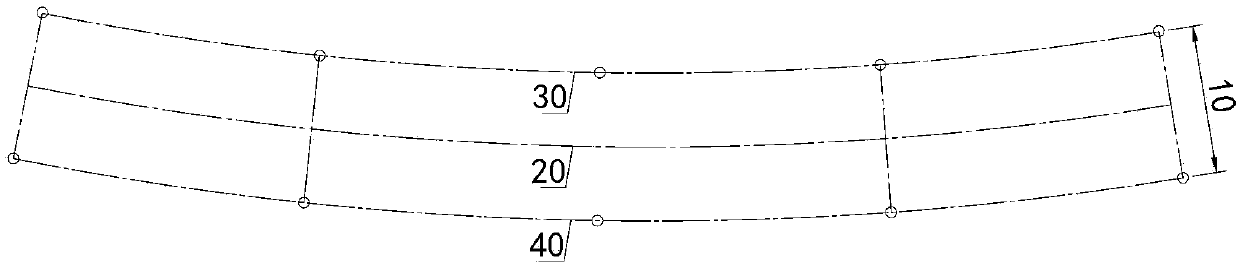

[0033] see figure 1 As shown, the embodiment of the present invention provides a bending node for connecting two adjacent main truss members in a steel truss girder bridge, each main truss member includes an upper chord, a lower chord and a web, and the bending The hinge point 2 is divided into two connecting sections 21 and a bending section 22 arranged between the two connecting sections 21. The end of each connecting section 21 is a free end for connecting the upper chord or the lower chord. The node 2 has a centerline 80 that runs through the two connecting sections 21 and the bent section 22, the centerline of the bent section 22 is an arc, the centerlines of the two connecting sections 21 are straight lines, and are connected through an arc transition, the two A bending angle α is formed between the centerlines of the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com