Rough rolling descaling method for hot-rolled steel billet

A steel billet and rough rolling technology, which is applied in the field of rough rolling and descaling of hot rolled steel billets, can solve the problems of poor practicability, poor anti-oxidation effect, and incomplete phosphorus removal, so as to reduce adhesion, reduce secondary oxidation, and improve phosphorus removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

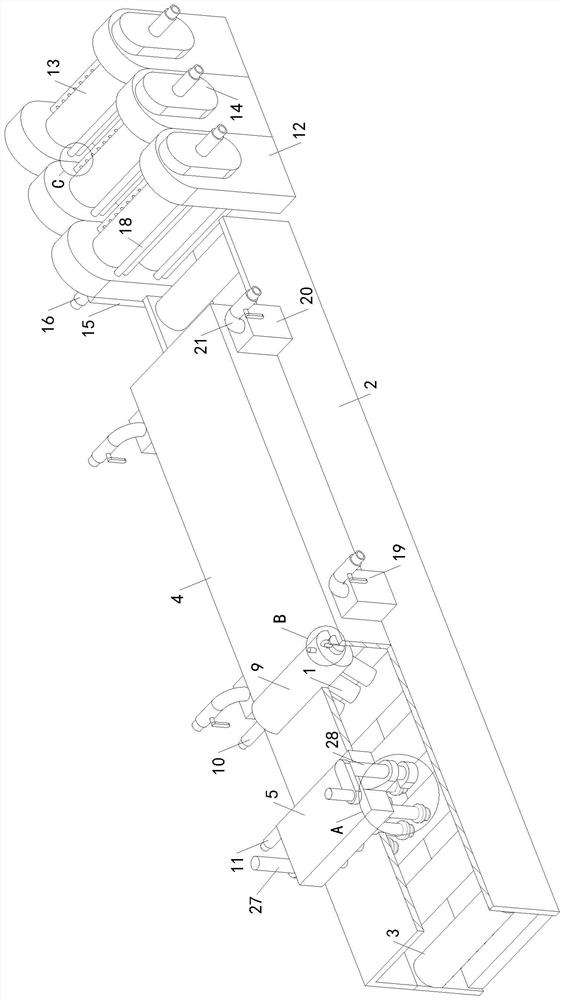

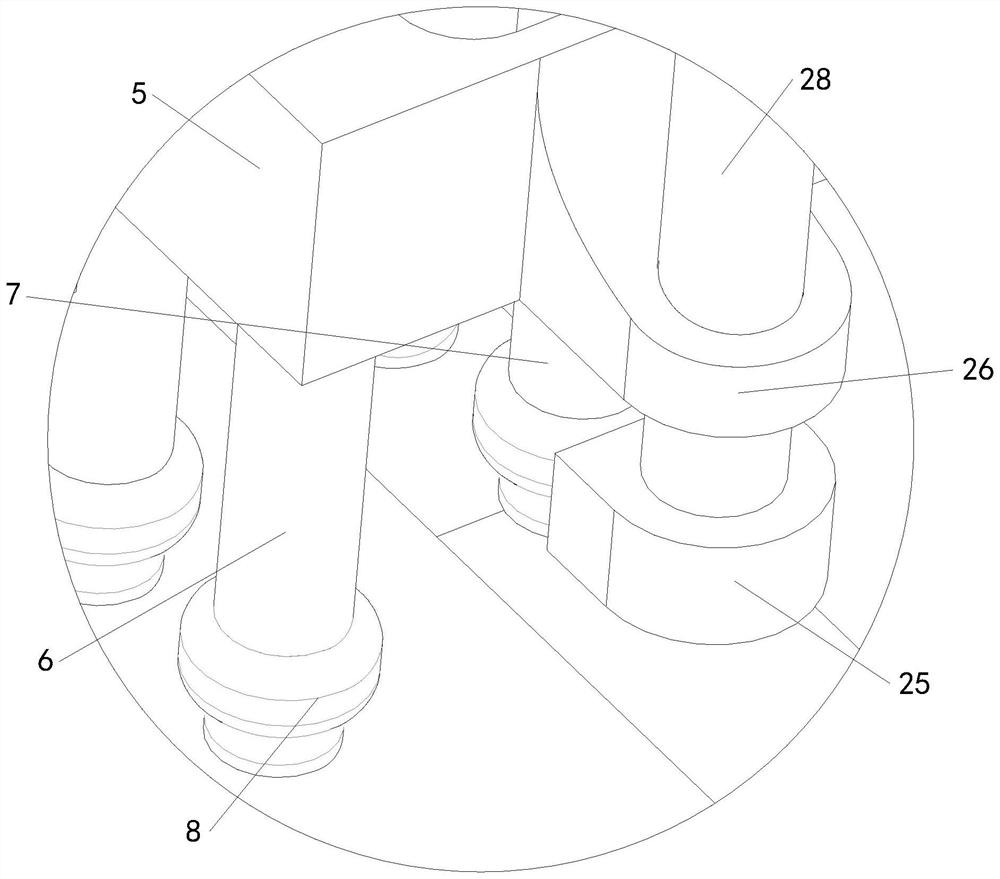

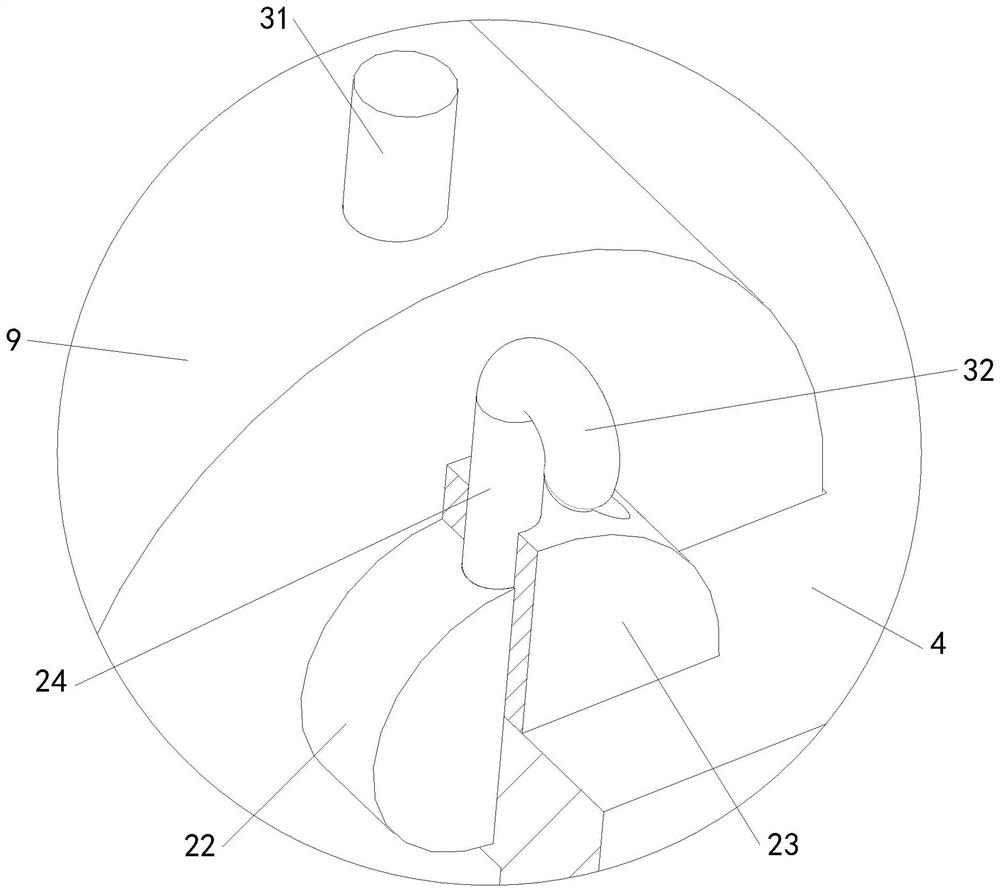

[0037] see Figure 1-7 , A method for rough rolling and descaling of a hot-rolled billet is realized based on a rough rolling and descaling system for a hot-rolled billet. The billet rough rolling production line, the hot-rolled rod billet rough rolling production line includes a conveying roller section 2 for billets, a plurality of power conveying rollers 3 are installed in the conveying roller section 2, and a cover frame 4 is connected to the conveying roller section 2, and the cover frame 4 The low-pressure water tank body 5 is installed on the upper through the lifting assembly. The lifting assembly includes two bottom ears 25 and two lifting ears 26. The two bottom ears 25 are fixedly connected to the front and rear ends of the cover frame 4 respectively. A polished rod 27 and a threaded rod 28 are respectively connected, and the two lifting ears 26 are fixedly connected to the front and rear ends of the low-pressure water tank body 5 respectively. The two lifting ears ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com