Method of Constructing Steel-concrete Composite Beams Using Cross Cables

A steel-concrete composite beam, cross-type technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as material waste, achieve broad application prospects, uniform force, and reduce engineering costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

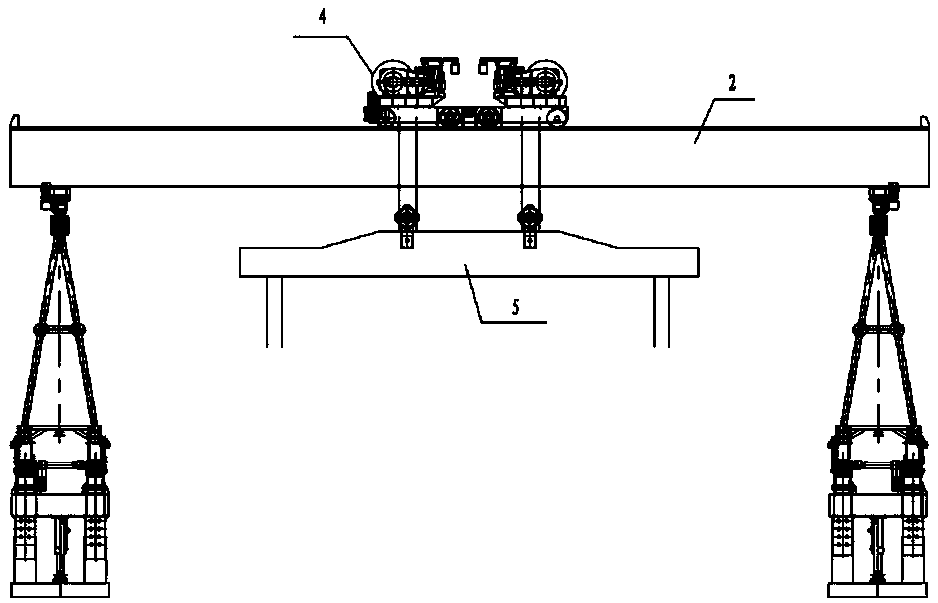

[0034] The construction method of the present invention will be described in more detail below by taking the steel-concrete continuous composite beam with seven holes and one connection as an example, wherein the span range of each steel beam unit is 30-120m, which is more suitable:

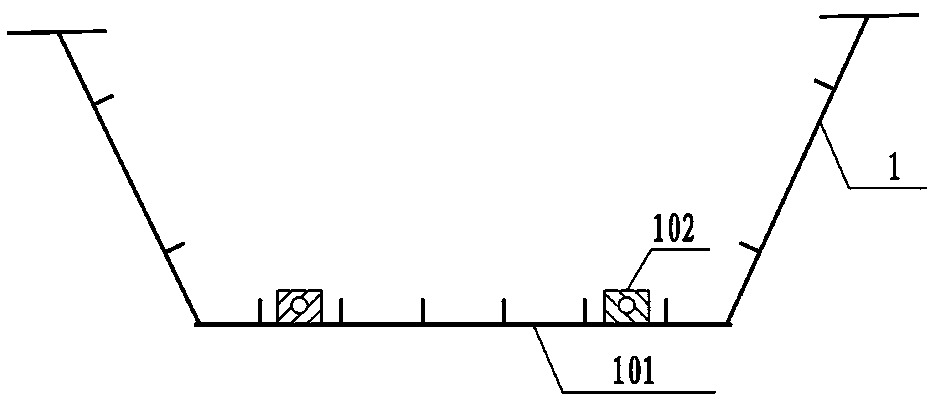

[0035] In the first step, according to the design requirements, the steel beam unit 1 for each hole is prefabricated, and six temporary hanging pieces 102 are arranged at intervals on the bottom plate 101 of the steel beam unit, such as figure 1 shown; if the span is large, the number of temporary hanging pieces can be increased;

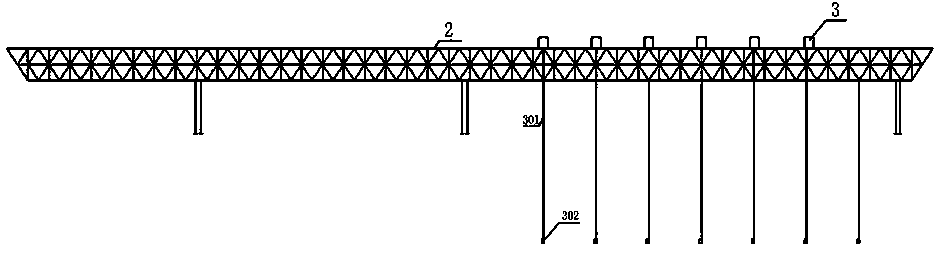

[0036] In the second step, according to the span of the steel beam unit in each hole, six groups of cable devices 3 are designed at intervals on the crossbeam of the bridge erecting machine 2, and the bottom of the cable 301 of each cable device 3 is provided with a corresponding temporary hanging piece 102. Hanging buckle 302, wherein the number of cable devices 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com