Simple and convenient thermal insulation structure wallboard, wall structure and wall manufacturing method

A simple, wall panel technology, applied in the direction of thermal insulation, building structure, wall, etc., can solve the problems of unstable combination of composite thermal insulation board and base wall, high cost and low construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

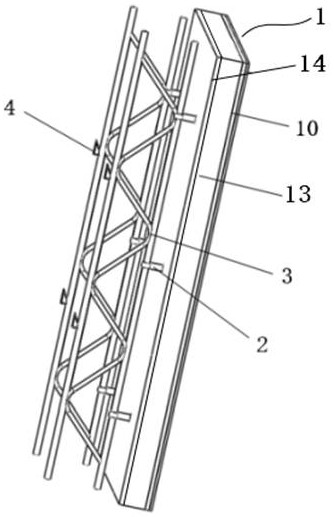

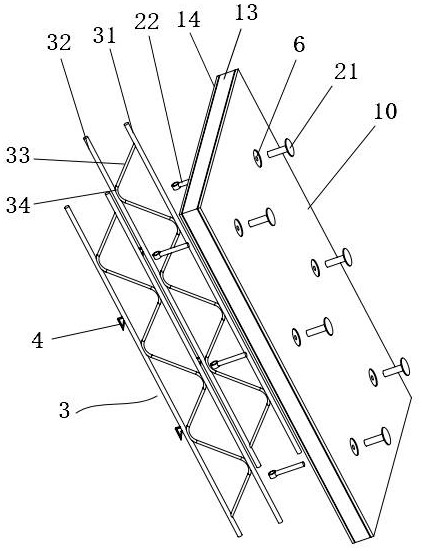

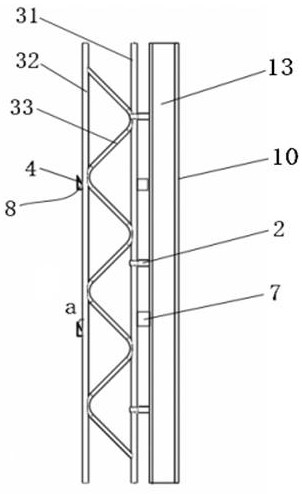

[0037] Such as Figure 1 to Figure 4 As shown, the present invention provides a simple thermal insulation structure wall panel, comprising a composite thermal insulation board 1, an anchor connector 2 is arranged on the composite thermal insulation board 1, and the inner end of the anchor connector 2 is connected from the inner surface of the composite thermal insulation board 1 Going out, the inner end of the anchor connector 2 is connected with a reinforcement frame 3, and each composite insulation board 1 can be provided with a reinforcement frame 3, or two or more parallel reinforcement frames 3, and the reinforcement frame Sheet 3 includes outer reinforcement 31 and inner reinforcement 32. The inner reinforcement 32, outer reinforcement 31 and composite insulation board 1 are arranged in parallel. 32 has a plurality of connection points 34, the outer reinforcement 31 is located on the side close to the composite insulation board 1, the inner reinforcement 32 is located on...

specific Embodiment approach 2

[0042] Such as Figure 5 As shown, this specific embodiment provides a wall structure, including the base wall 100 and any simple thermal insulation structure wall panel in Embodiment 1, the simple thermal insulation structure wall panel has several pieces and is connected with the base wall 100 are fixedly connected, and the steel frame sheet 3 is provided with a transverse tie bar 9, the steel bar frame sheet 3 and the transverse tie bar 9 are located in the base wall 100, and the composite insulation board 1 is located outside the base wall 100.

specific Embodiment approach 3

[0043] This specific embodiment provides a construction method for a wall structure, including the simple thermal insulation structure wallboard described in specific embodiment 1, and also includes the following steps:

[0044] A1: To support the external formwork, first connect the steel bar frame piece 3 to the composite thermal insulation board 1 through the anchor connector 2, and erect the assembled thermal insulation structure wall panel. The outer side of the composite thermal insulation board 1 is used as the external template, or as a metal external template The built-in thermal insulation board is attached to the inner surface of the metal formwork, and the steel frame piece 3 is rotated to a position perpendicular to the surface of the composite thermal insulation board 1;

[0045] A2: Place horizontal tie reinforcement 9 at the corner of the middle abdominal reinforcement 33 to connect the planar reinforcement frame sheet 3 into a three-dimensional reinforcement gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com