Method of Constructing Steel-Concrete Composite Beams Using Mixed Cables

A technology of steel-concrete composite beams and steel beams, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of material waste, affecting the working performance and service life of composite continuous beams, concrete cracking, etc., and achieve broad application prospects , Improve material utilization efficiency and reduce project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

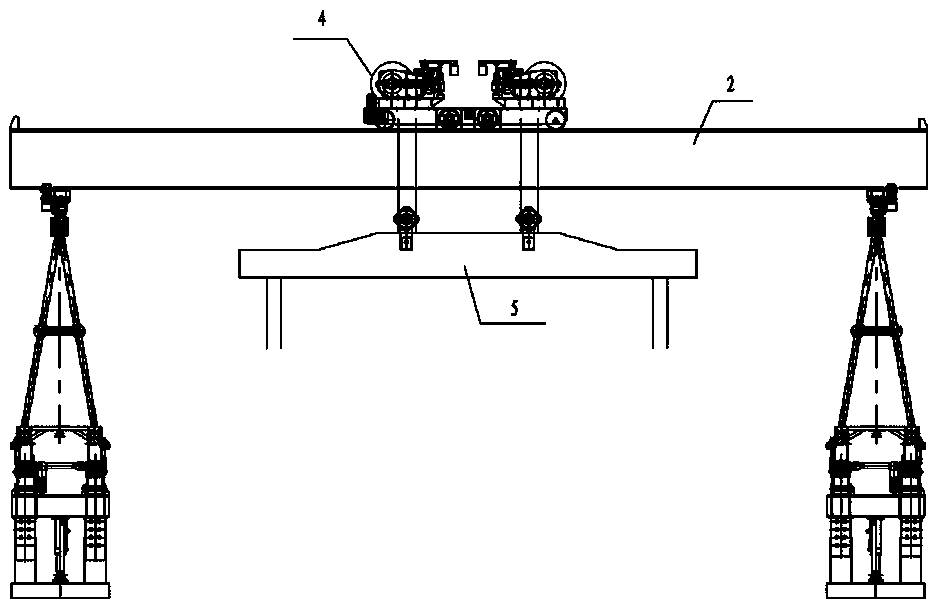

[0035] The construction method of the present invention will be described in more detail below by taking the steel-concrete continuous composite beam with seven holes and one connection as an example, wherein the span range of each steel beam unit is 30-120m, which is more suitable:

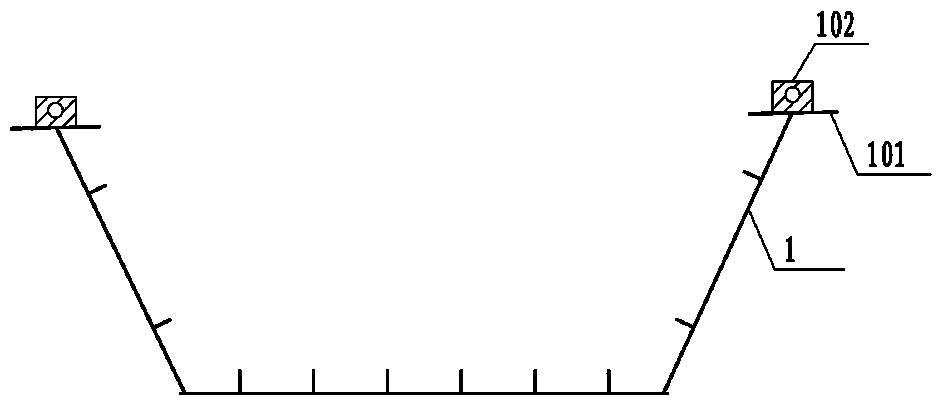

[0036] The first step is to prefabricate the steel beam unit 1 for each hole according to the design requirements, and set five temporary hanging pieces 102 at intervals respectively on the upper flange 101 of the steel beam unit, such as figure 1 shown; if the span is large, the number of temporary hanging pieces can be increased;

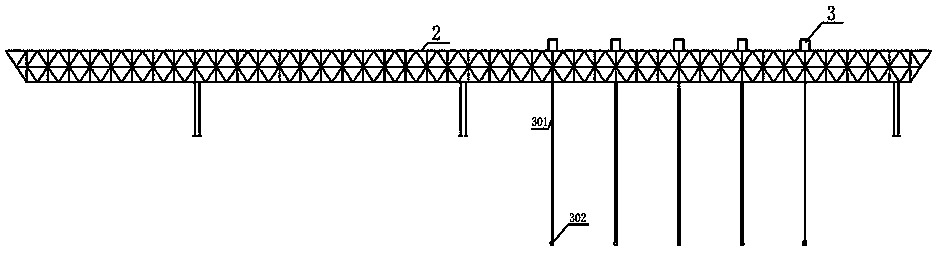

[0037] In the second step, according to the span of the steel beam unit in each hole, five sets of cable devices 3 are designed at intervals on the crossbeam of the bridge erecting machine 2, and the bottom of the cable 301 of each cable device 3 is provided with a corresponding temporary hanging piece 102. Hanging buckle 302, wherein the number of cable devices 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com