U-shaped groove for water conservancy work construction

A farmland water conservancy and U-shaped trough technology, applied in application, construction, agriculture, etc., can solve the problems of soil hardening, difficult access of large equipment, slow efficiency, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

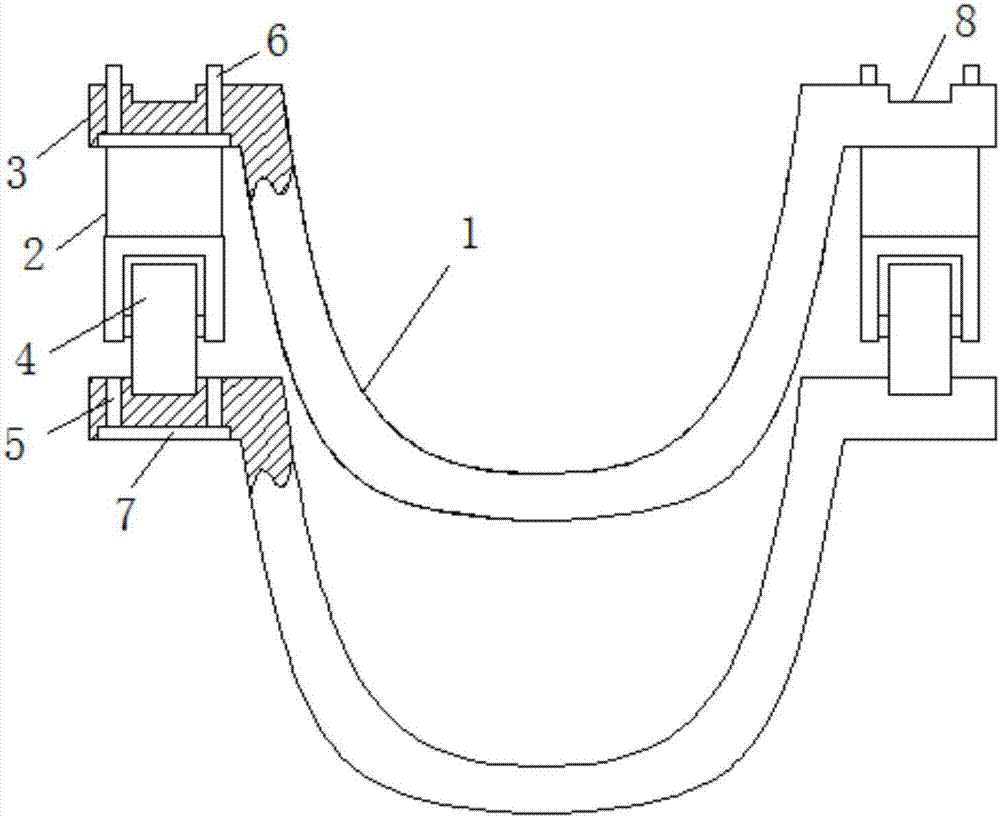

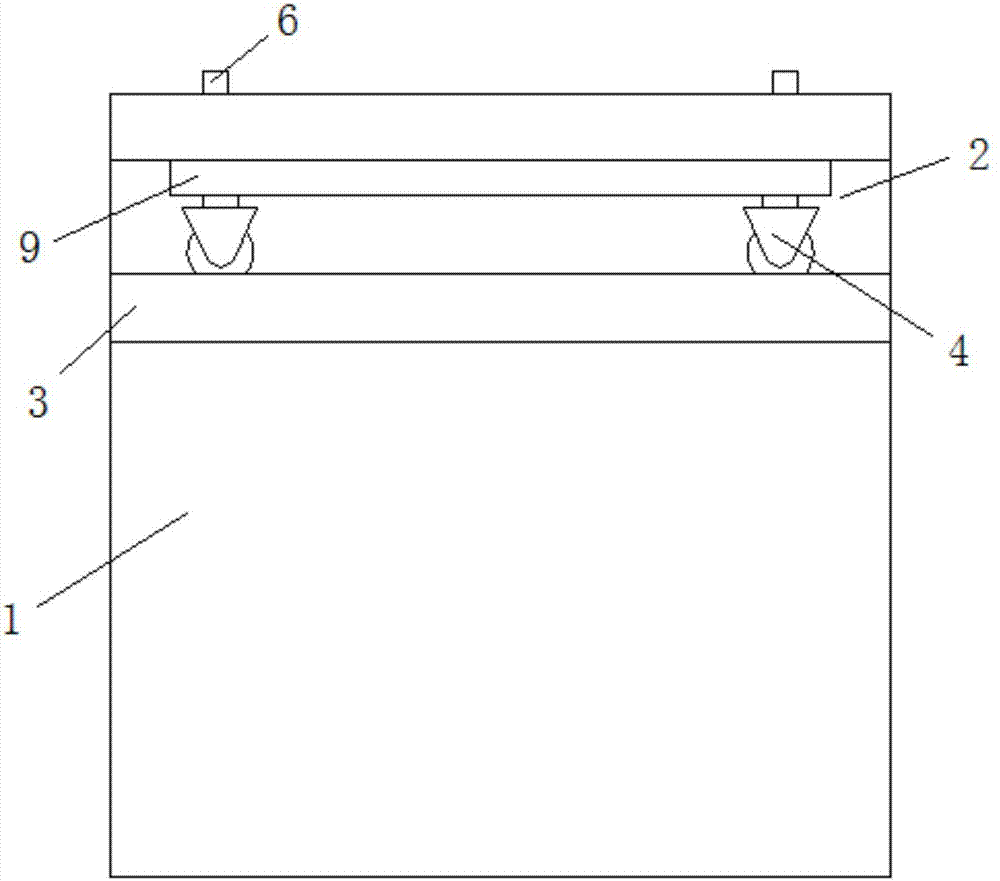

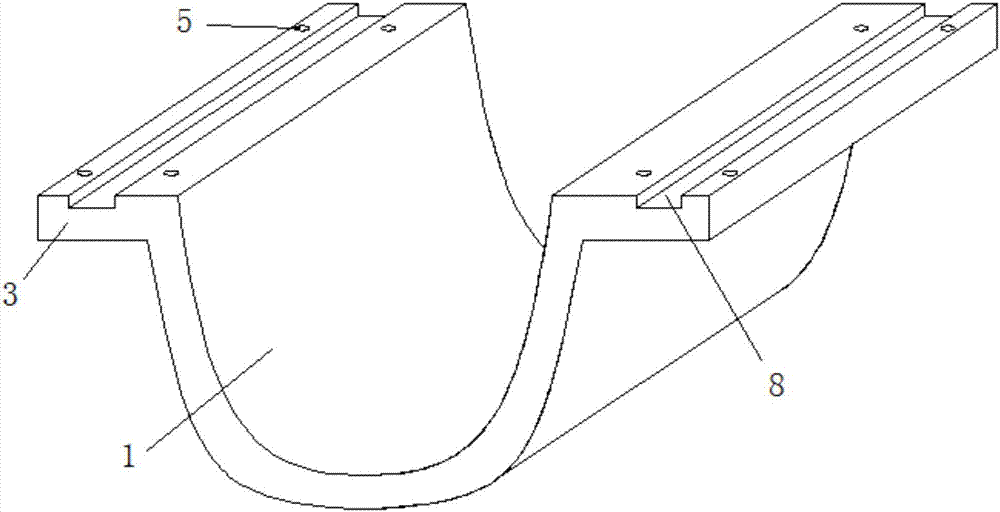

[0018] Such as Figure 1-3 As shown, a U-shaped trough for farmland water conservancy construction, including a trough body 1 and a running device 2 for transferring the trough body 1, the straight side of the trough body 1 is provided with an outwardly extending extension wing 3, and the trough body 1 is supported on the running gear 2 by the extension wing 3. The running device 2 includes a support plate 9 and a roller 4 fixed on the lower surface of the support plate 9 .

[0019] In this embodiment, the upper surface of the support plate 9 is provided with a plug-in column 6, and the extension wing 3 is provided with a plug-in hole 5, and the extension wing 3 is fixed on the On the support plate 9, the upper surface of the extension wing 3 is provided with a square groove 8 in the direction of water flow, the width of the square groove 8 is greater than the width of the roller 4, and the insertion holes 5 and the insertion columns 6 are double-row structures, And be posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com