CF common rail system

A common rail system and common rail technology, applied in the field of CF common rail system, can solve the problem that the high-pressure common rail fuel injection system cannot be used for small and medium-sized diesel engines, etc., and achieve small size, high fuel supply efficiency, and good manufacturability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

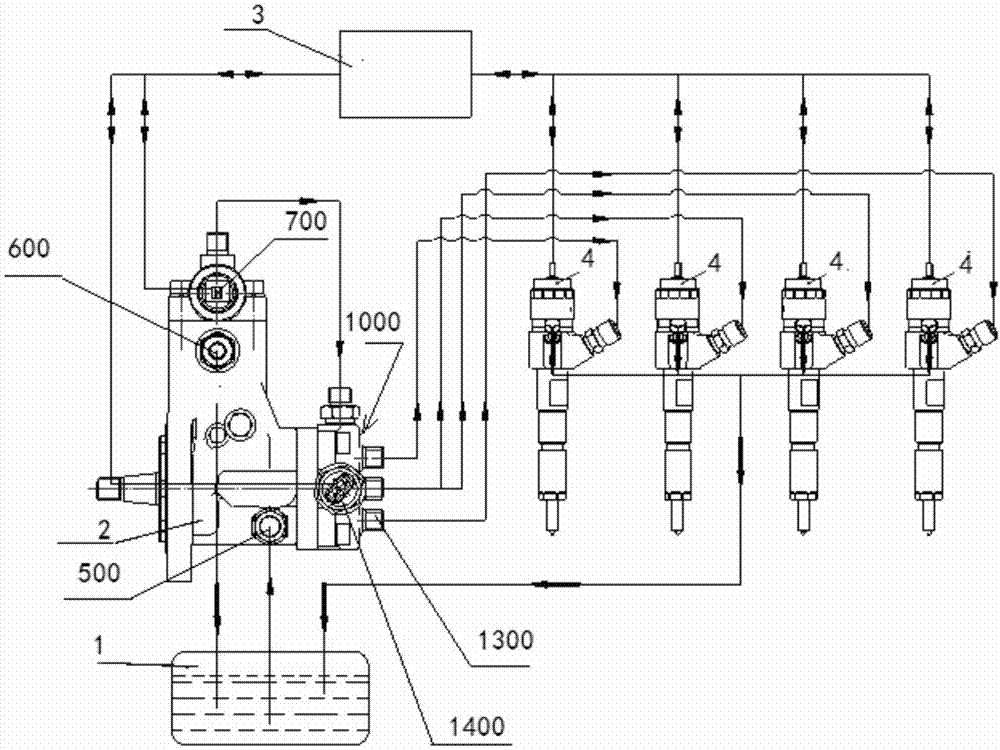

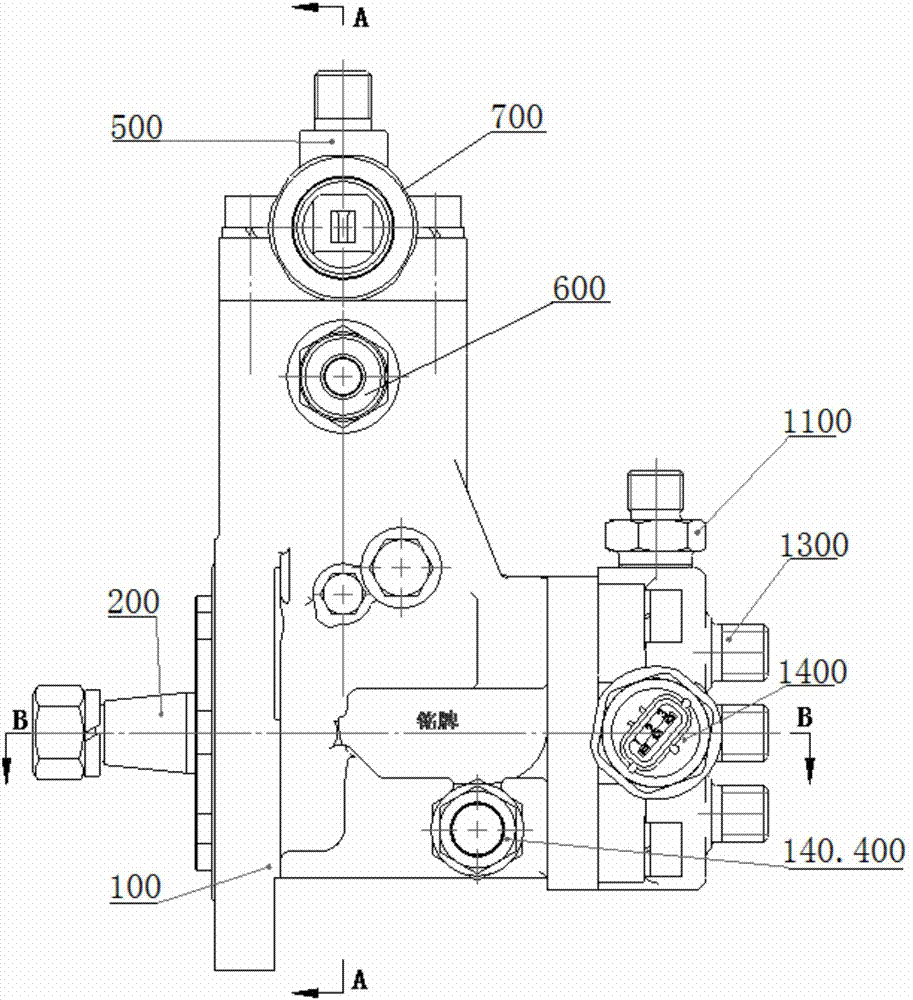

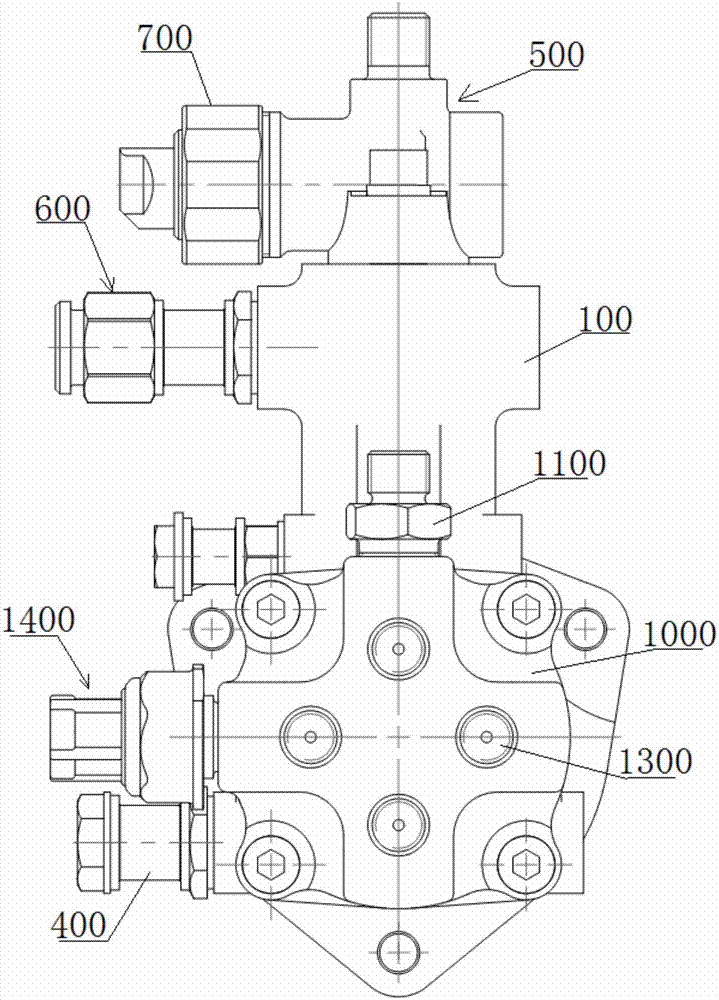

[0035] see figure 1 , figure 1 A CF common rail system shown in , including a fuel tank 1, a pump, a rail-integrated common-rail fuel supply pump 2, an ECU 3, four fuel injectors 4, and an oil delivery pump 600 in the pump and rail-integrated common-rail fuel supply pump 2 The oil inlet of the pump is communicated with the fuel tank 1 through the oil pipe, and the outlet of the pressure stabilizing valve part 600 in the pump and rail integrated common rail fuel supply pump 2 is communicated with the fuel tank 1 through the oil pipe; The four oil outlet joints 1300 on the compressor 1000 are connected with the oil inlet pipe joints on the four injectors 4 through high-pressure oil distribution pipes.

[0036] The pressure sensor 1400 in the pump and rail integrated common rail fuel supply pump 1 is connected to the signal of ECU3, and the ECU3 is also connected to the pump and the electromagnet in the electromagnetic valve part 700 of the rail integrated common rail fuel suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com