Novel LED lamp light-guiding structure

A technology of LED lamp and light guide structure, which is applied in the direction of light source, semiconductor device of light-emitting element, lighting device, etc., can solve the problems of affecting the uniformity of light output, complicated manufacturing process, low space utilization rate, etc., and achieves uniform and moderate brightness. The effect of good uniformity and less light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

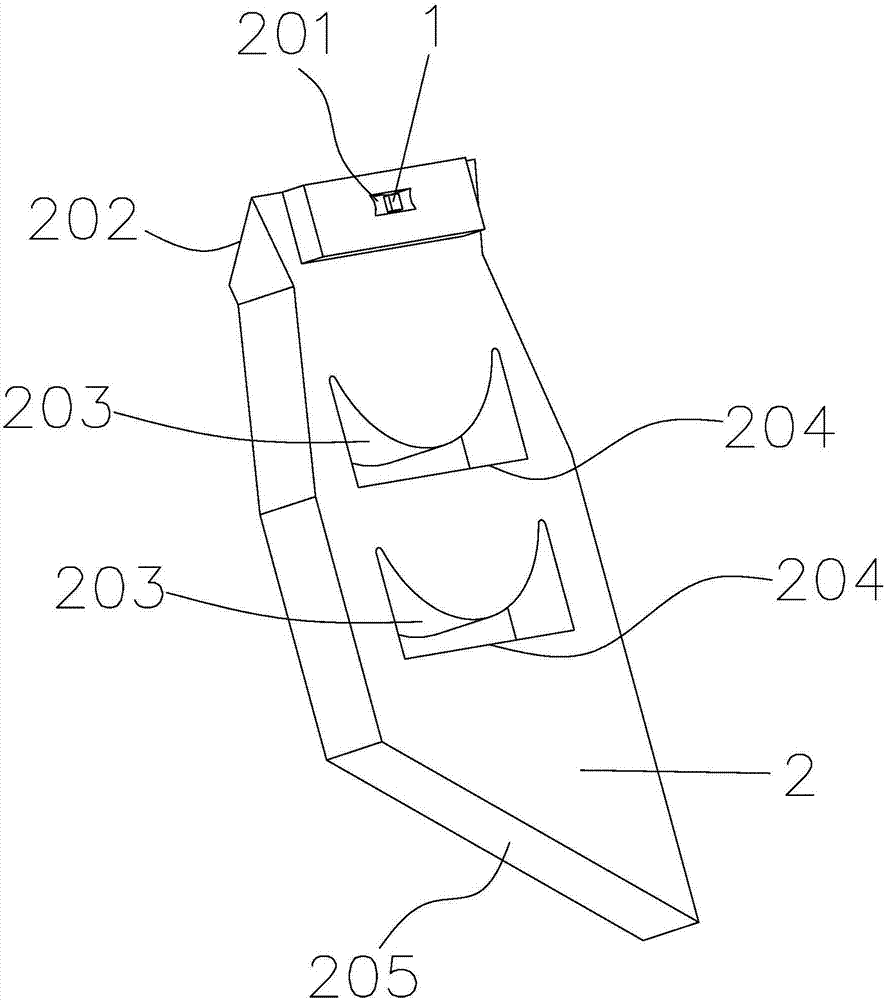

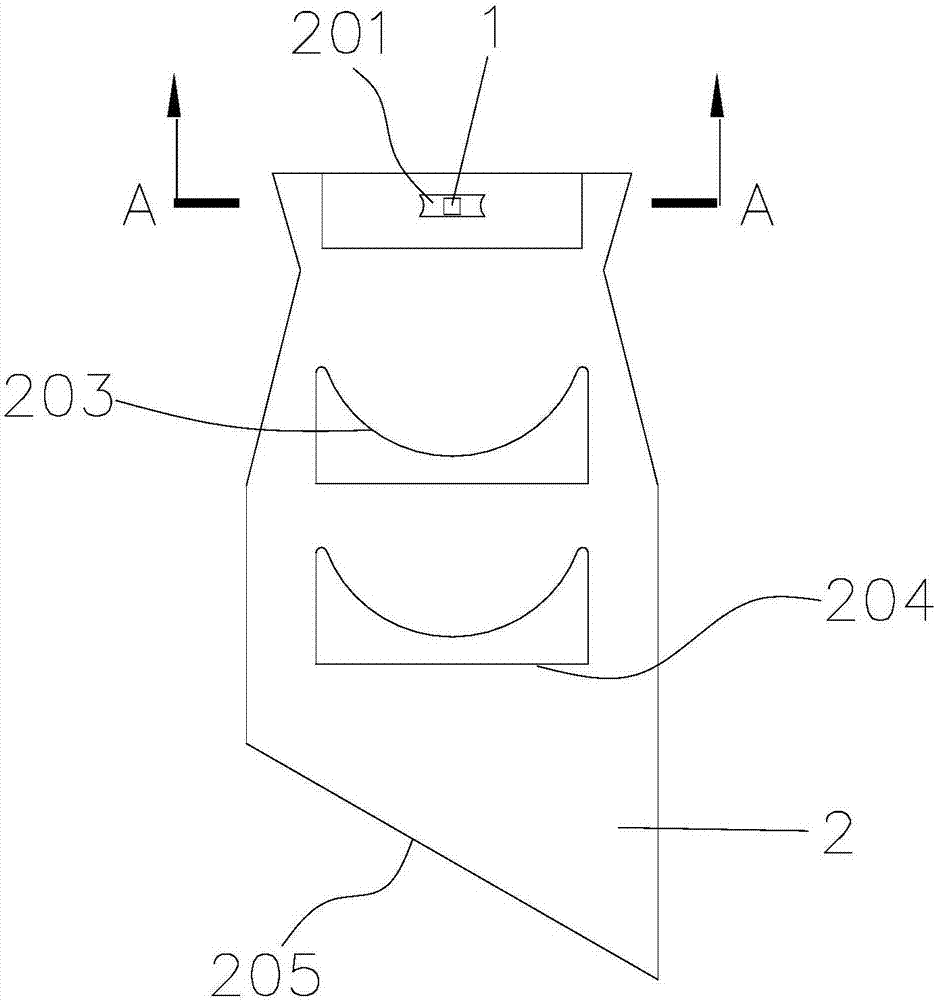

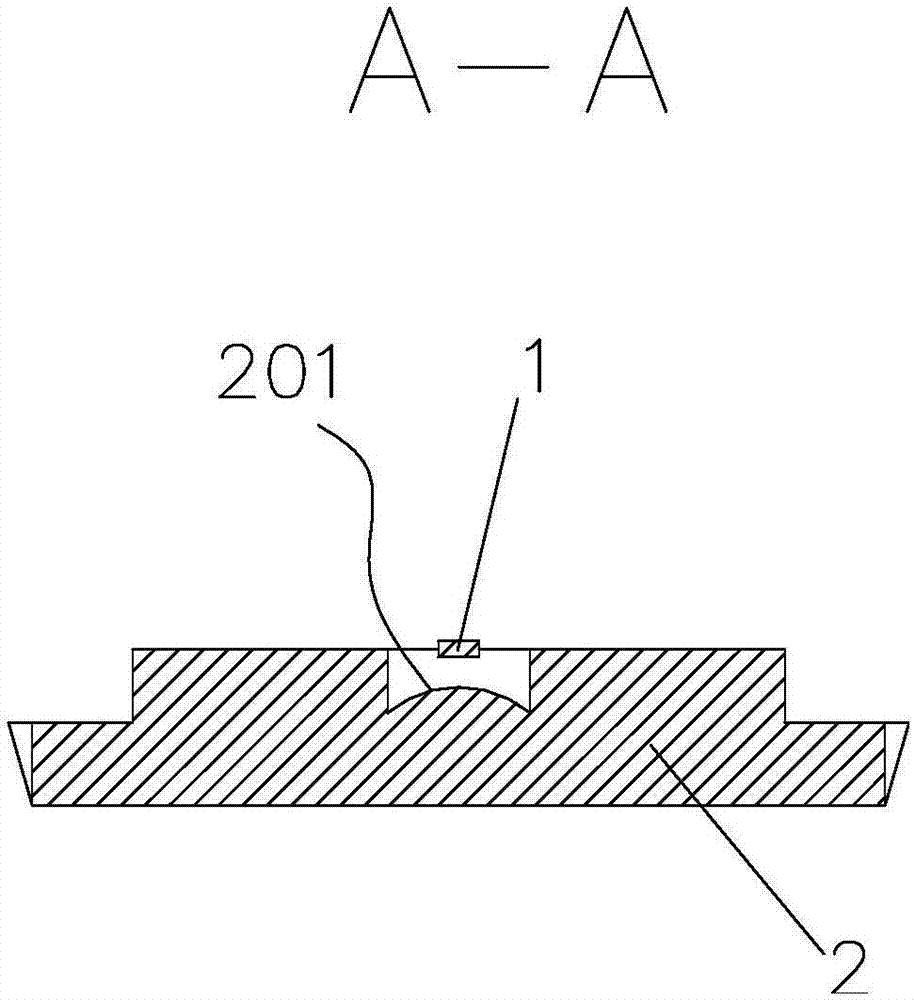

[0026] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0027] Such as Figure 1-Figure 4 Shown is a specific embodiment of a novel LED light guide structure of the present invention, which includes an LED light source 1 and a light guide block 2. The light guide block 2 is provided with an inlet convex surface 201 and a total reflection surface 202, and the LED light source 1 faces The inlet convex surface 201 and the total reflection surface 202 are used for total reflection of the refracted light from the inlet convex surface 201; the light guide block 2 is evenly distributed with a number of light-gathering grooves in the reflection direction of the total reflection surface 202, and the light-gathering grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com