Sensor of oil burning pump

A sensor and fuel pump technology, applied in instruments, liquid level indicators, float level indicators, etc., to achieve the effect of solving the need for accurate display of instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

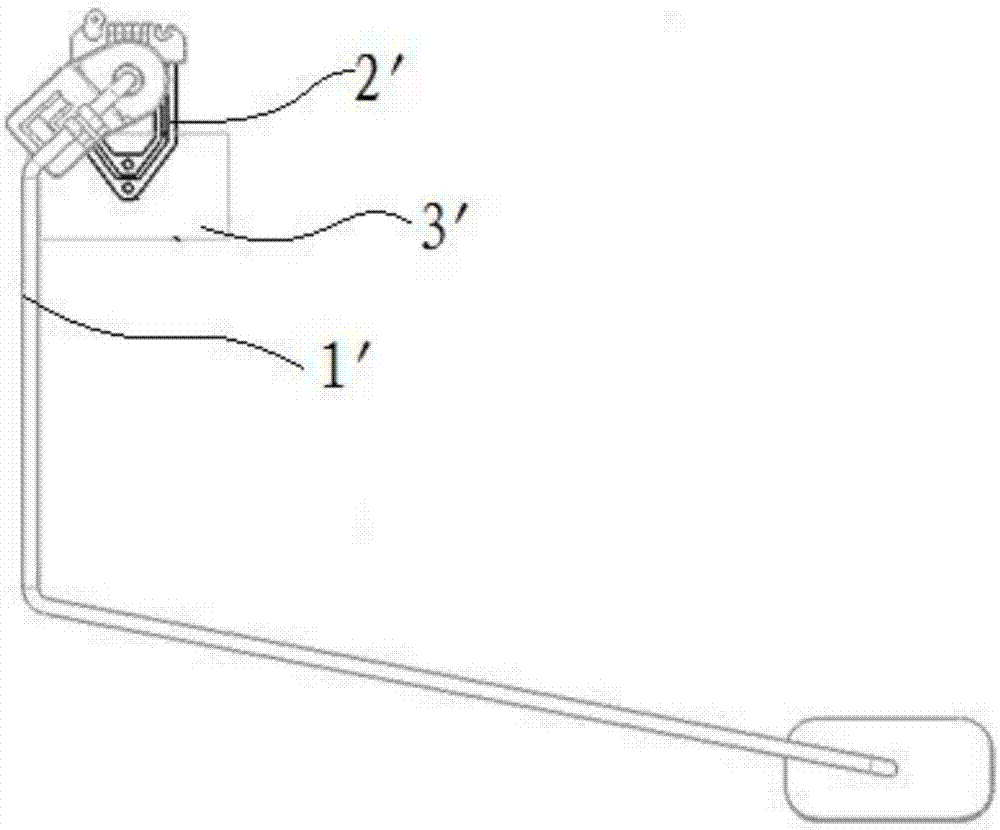

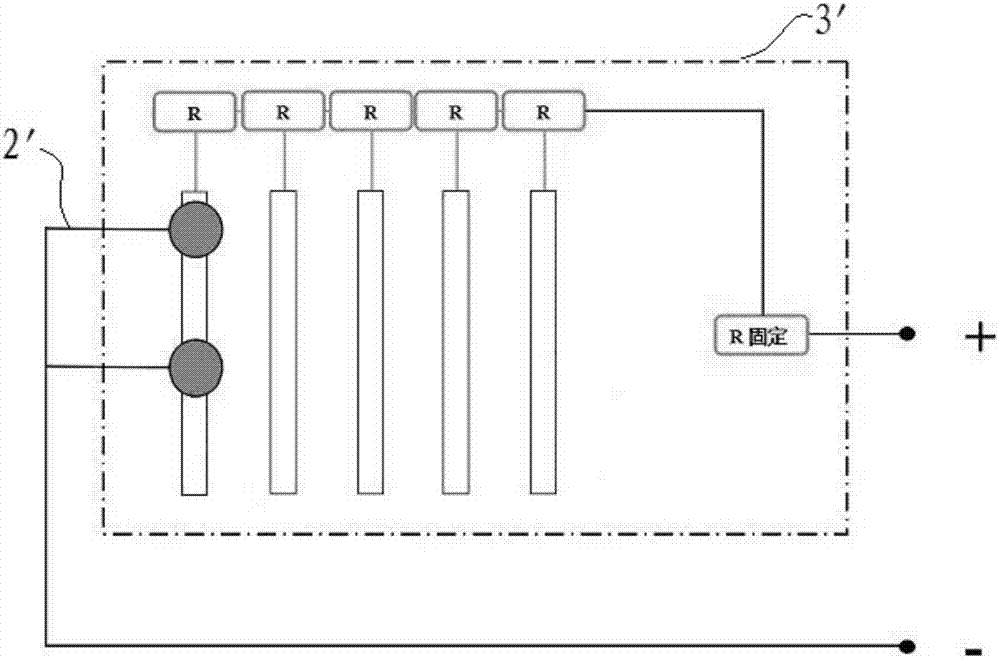

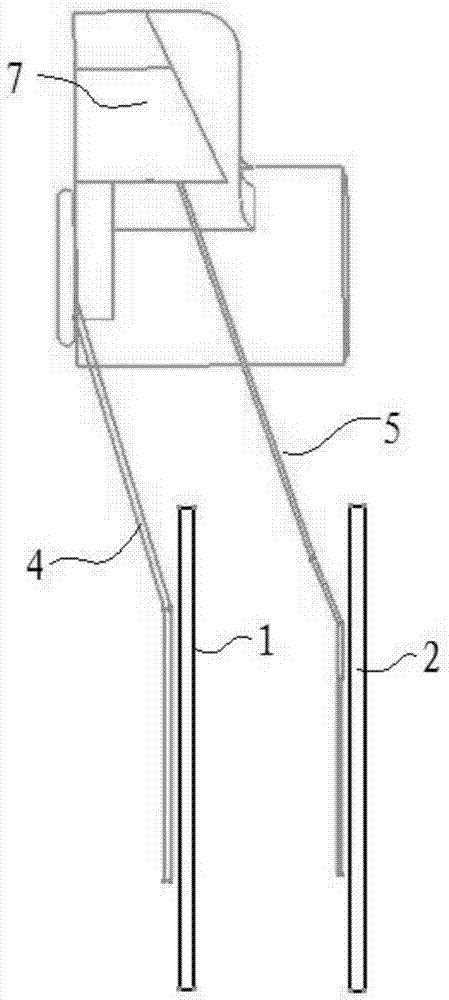

[0022] Such as Figure 3 to Figure 6 As shown, the embodiment of the present invention provides a fuel pump sensor, including a casing and a float rod assembly 7 hinged on the casing, the float rod assembly 7 is rotatably fixed on the casing through a bearing, and the float One end of the rod assembly 7 is connected with a float, and when the oil level changes, the float rod assembly 7 is controlled by the float to rotate, and the housing is provided with a first resistance sheet 1 and a second resistance sheet 2, and the first resistance sheet 1 and the The second resistance piece 2 is electrically connected to the input lead 3 after being connected in parallel, and the electrical connection end of the float rod assembly 7 is equipped with a first reed 4 for contacting with the first resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com