Uniform-thickness 3mm high-light-transmission zero-temperature-drift optical structure and imaging method thereof

A technology of optical structure and large-pass light, applied in optics, optical components, installation, etc., can solve problems such as difficult high resolution, day and night confocal, high and low temperature sensitivity, and large day and night defocus, achieving small day and night defocus, The effect of low sensitivity and low color distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

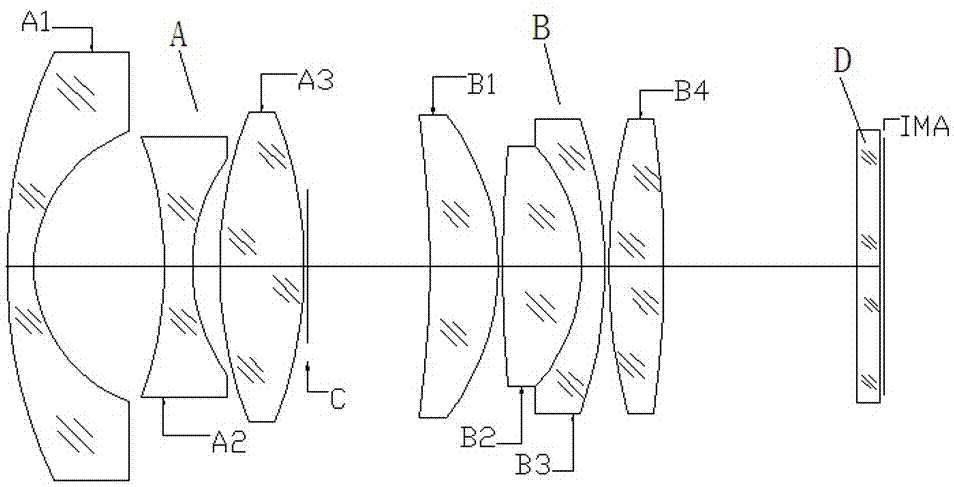

[0022] like figure 1 As shown, the present invention has an equal-thickness 3mm Datong optical zero-temperature-drift optical structure, including a front group of lenses A, a diaphragm C, and a rear group of lenses B that are sequentially arranged along the incident direction of light from left to right, and the front group of lenses A It includes a meniscus negative lens A1, a biconcave negative lens A2, and a biconvex positive lens A3 arranged in sequence from left to right; A cemented group consisting of lens B2 and meniscus negative lens B3 in close contact, and biconvex positive lens B4.

[0023] In this embodiment, the air gap between the front lens group A and the rear lens group B is 2.7mm.

[0024] In this embodiment, the air interval between the meniscus negative lens A1 and the biconcave negative lens A2 is 3.2mm, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com