A kind of low-impedance flame-retardant supercapacitor electrolyte and preparation method thereof

A supercapacitor and electrolyte technology, applied in the direction of hybrid capacitor electrolyte, etc., can solve problems such as potential safety hazards and easy safety accidents, and achieve the effects of avoiding accidents, improving electrochemical performance, and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

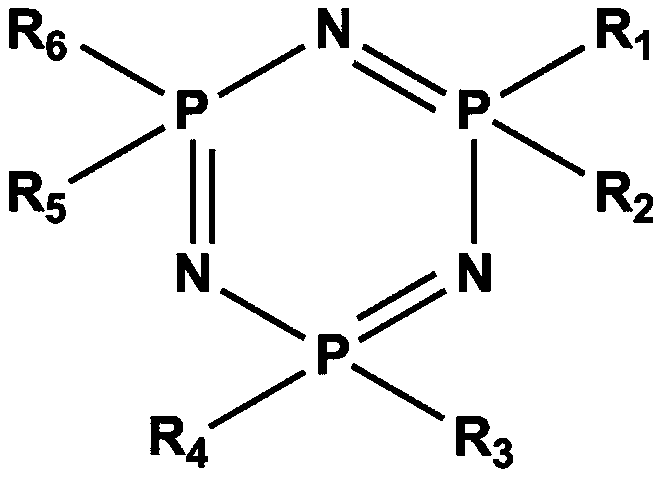

[0055] Preparation of siloxypentafluorocyclotriphosphazene: add 50g NaF to 100g of acetonitrile with siloxypentafluorocyclotriphosphazene, and carry out fluorination reaction at 70°C for 4 hours, then distill Siloxypentafluorocyclotriphosphazene is obtained.

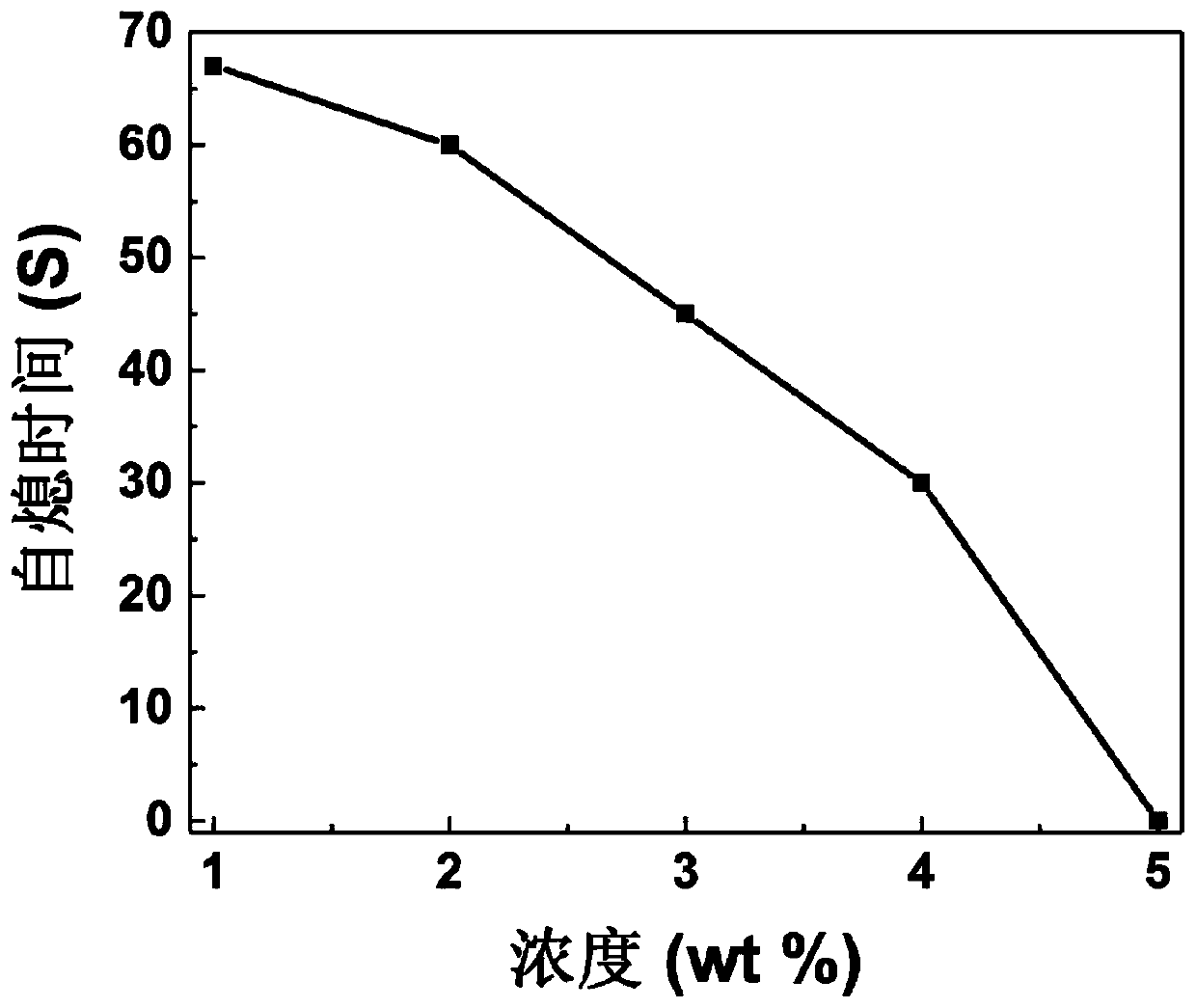

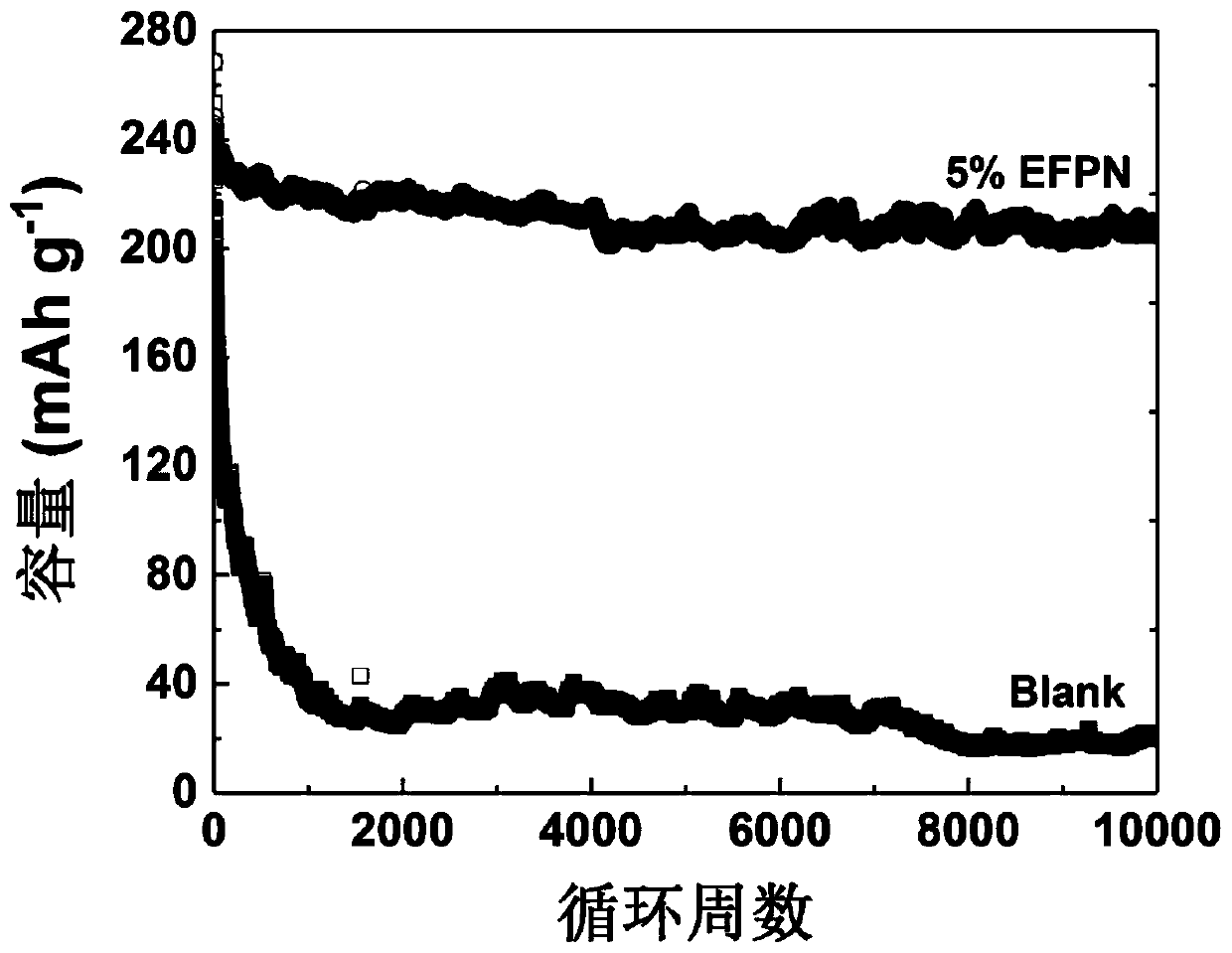

[0056] The above-mentioned siloxy pentafluorocyclotriphosphazene was prepared into an electrolyte solution, and its flame retardancy and cycle performance were tested. The results were as follows: Figure 1-2 shown.

Embodiment 2

[0058] The preparation process of 1-propoxy-pentafluorocyclotriphosphazene: put 15g of hexafluorocyclotriphosphazene in 180ml of chlorobenzene, add the catalyst ferric chloride and 3.2 grams of sodium propoxide under constant stirring, and set the temperature at 80°C , reacted for 5 hours, and distilled under reduced pressure to obtain a phosphazene derivative: 1-propoxy-pentafluorocyclotriphosphazene.

Embodiment 3

[0060] The preparation process of hexaphenoxycyclotriphosphazene: 34.8g of hexachlorocyclotriphosphazene crystals and hexane are placed in a 500ml three-necked bottle with a stirrer, a thermometer, and a back distillation condenser, and stirred until it dissolves evenly. React with 50g of sodium phenate for 10 hours at 80°C, distill and refine to obtain a phosphazene derivative: hexaphenoxycyclotriphosphazene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com