Motor and electric tool

A power tool, working technology, applied in the field of power tools, motors that drive power tools to work, and power tools of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0199] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the attached drawings are only for reference and description, and are not used to limit the present invention.

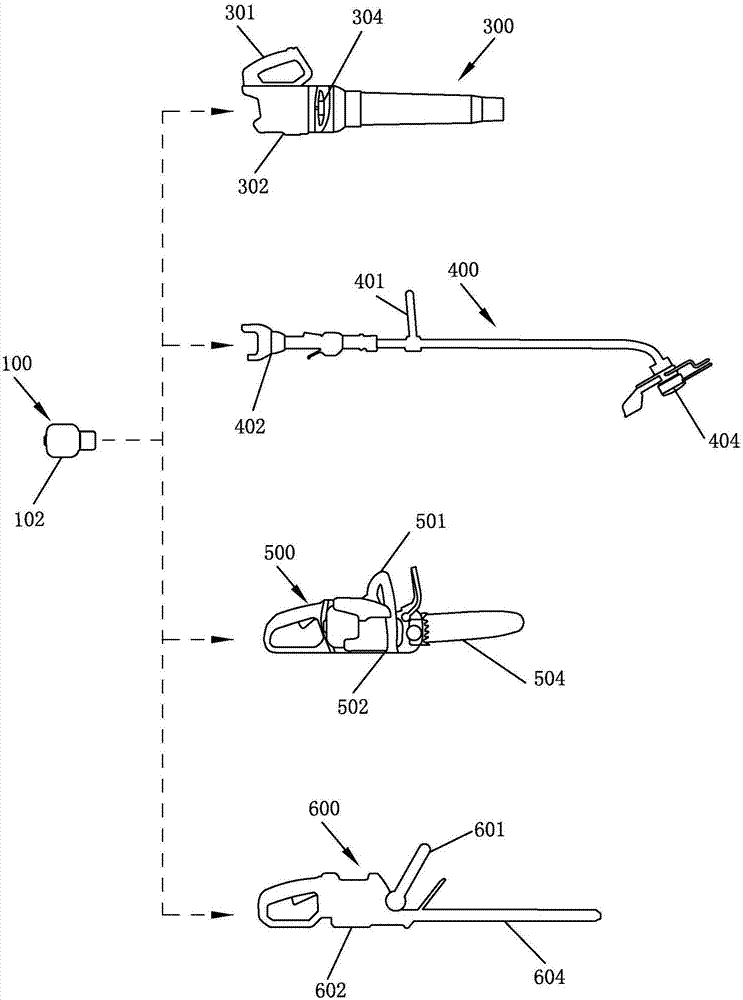

[0200] Such as figure 1 Shown is a schematic structural diagram of an electric tool system in a preferred embodiment. The power tool system includes a power device 100 and at least two tool bodies of the power tool, wherein the power device 100 is detachably installed with the tool bodies of the at least two power tools to provide power for the tool bodies of the at least two power tools. In this embodiment, there are four kinds of tool bodies included in the power tool system, which are respectively a blower tool body 300, a lawnmower tool body 400, a chainsaw tool body 500, and a pruning shears tool body 600. All four kinds of tool bodies are provided with the same interface for installing the power device 100. The aforementioned...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap