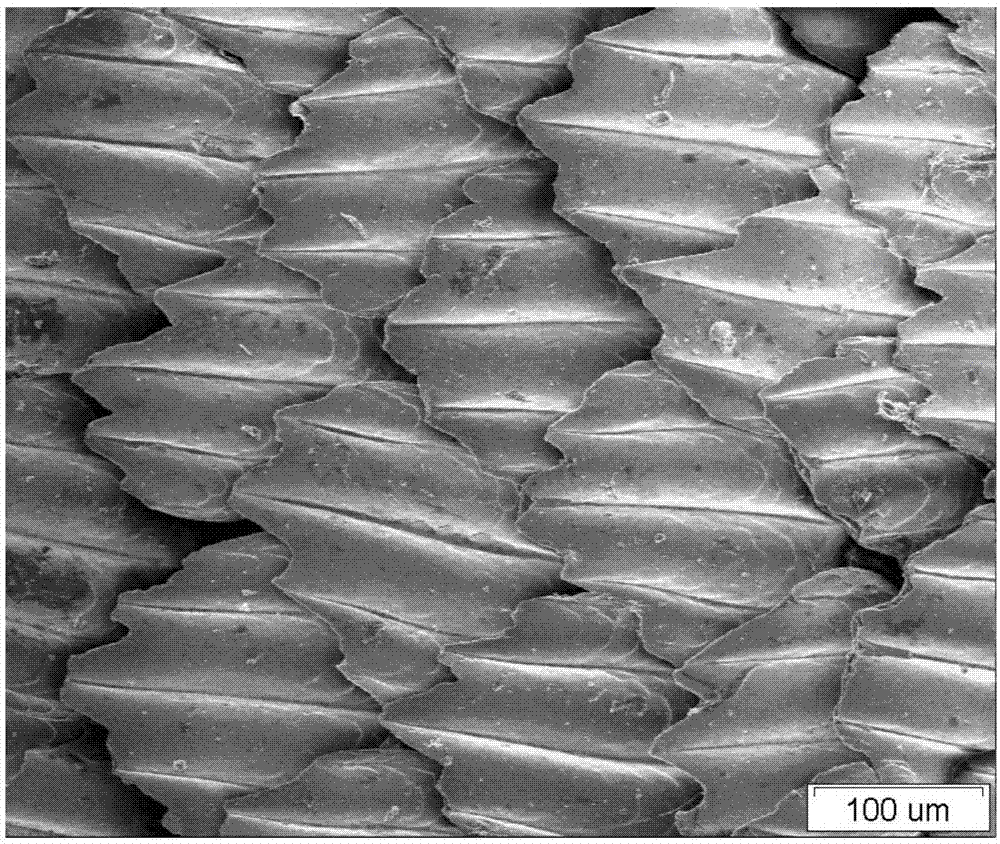

Shark scale-like fisheye screen

A technology imitating sharks and fish eyes, applied in the direction of filter screen, solid separation, grille, etc., can solve the problem of low efficiency of one-way material push, achieve the goal of improving conveying efficiency and screening speed, reducing resistance, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

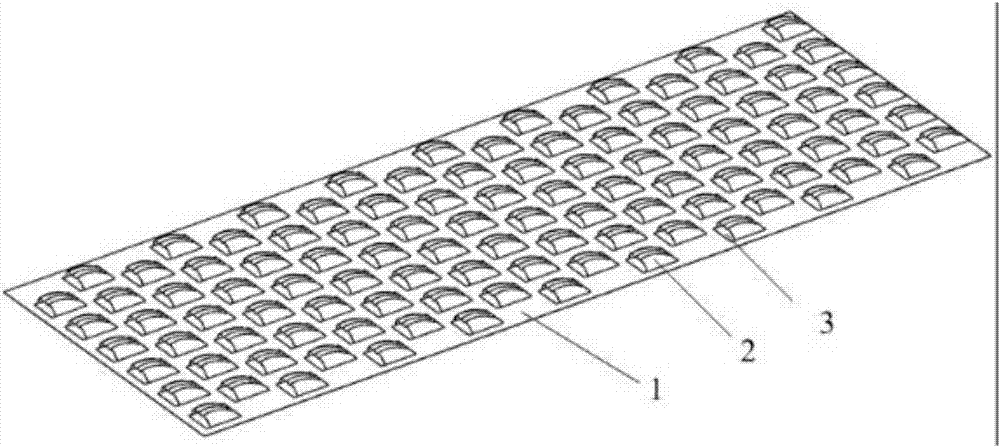

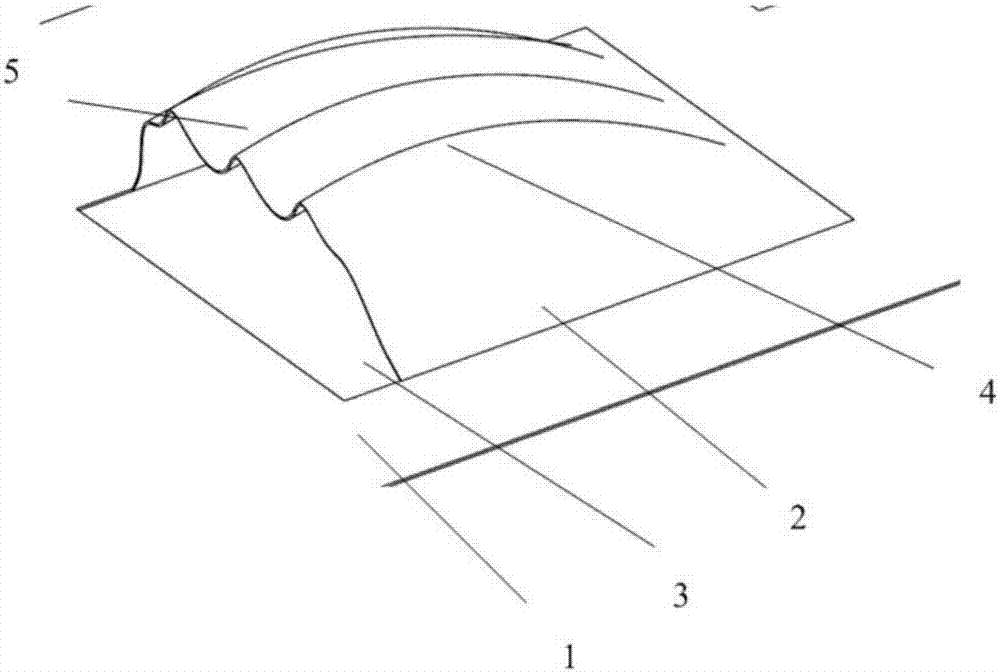

[0023] to combine Figure 1-3 Describe this embodiment, a fisheye sieve imitating shark scales in this embodiment, the fisheye sieve includes a sieve plate 1 and a fisheye sieve sheet 2; wherein: the sieve plate 1 is regularly provided with several fisheye sieves 2; the sieve plate 1 is also provided with a fisheye sieve 3 below each fisheye sieve 2; the fisheye sieve 2 is in the shape of a shark scale, and each fisheye sieve 2 is provided N protrusions 4 and N-1 grooves 5, wherein N is an integer ≥ 2.

[0024] In this embodiment, the preferred number of protrusions 4 is 2-5, and within this range better material pushing efficiency can be obtained, among which 3 have the best effect.

[0025] In this embodiment, the ratio of the width to the depth of the groove 5 is preferably (1-4):1, and better material pushing efficiency can be obtained within this range, and the effect of 2:1 is the best.

[0026] The working principle of the present invention is: the fisheye sieve is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com