Noise reduction and dust removal device for machining

A dust removal device and mechanical processing technology, which is applied in metal processing equipment, grinding/polishing safety devices, sounding equipment, etc., can solve the problems of polluting the processing environment, serious noise, and affecting the processing quality of workpieces, etc., to solve the problem of incomplete chip removal , reduce noise pollution, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

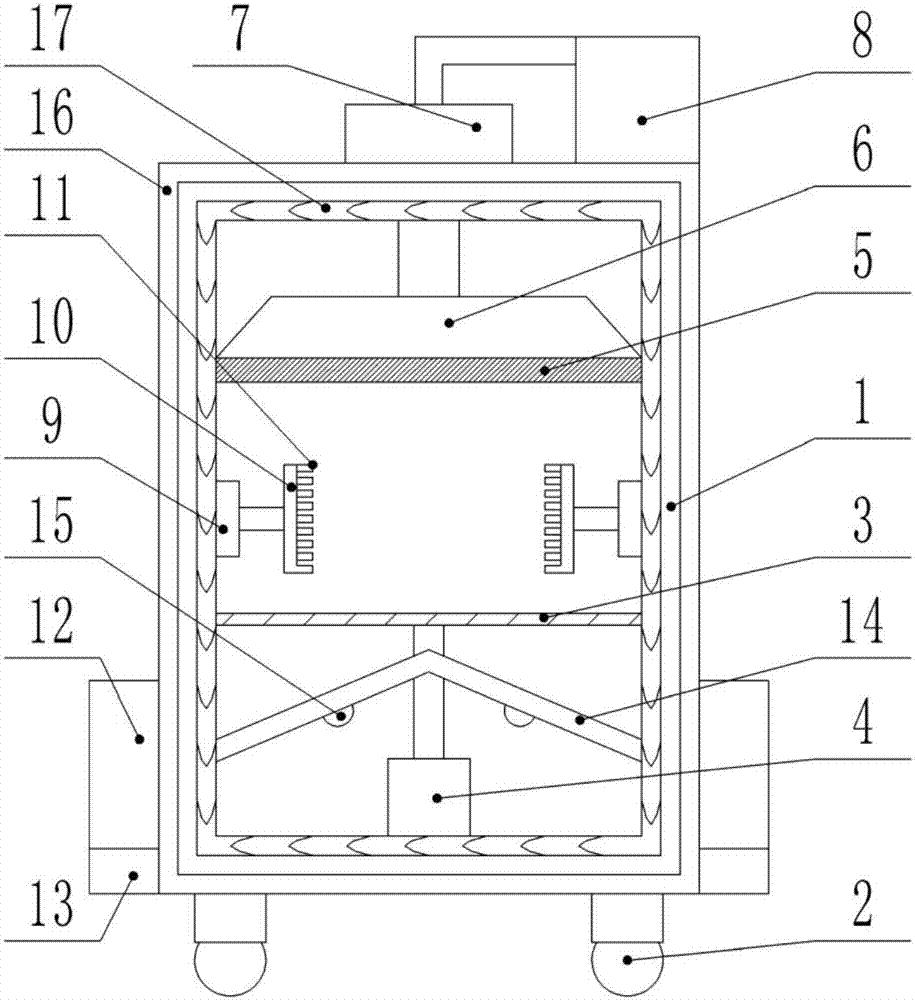

[0013] like figure 1 As shown, a noise reduction and dust removal device for mechanical processing includes a body 1, which is characterized in that, the inner wall of the body 1 is provided with a noise reduction layer 17 that is compatible with it, and the noise reduction layer 17 is filled with resistance Burning polyurethane, the noise reduction layer 17 is provided with a number of arc-shaped sound-transmitting holes, the outer wall of the body 1 is covered with a sound-absorbing cover 16, and the sound-absorbing cover 16 is made of glass fiber sound-absorbing cotton. Several rollers 2 are vertically arranged, and the rollers 2 are located below the sound-absorbing cover 16. The inside of the body 1 is provided with a guide plate 14 with a cone-shaped umbrella structure, and the guide plate 14 is installed on the body 1. On the inner wall of the guide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com