Rotary rolling die-cutting device

A rolling die and pressurizing device technology, applied in metal processing and other directions, can solve the problems of reduced strength, easily damaged die-cutting devices, cumbersome adjustments, etc., and achieve the effects of increasing service life, improving die-cutting accuracy, and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

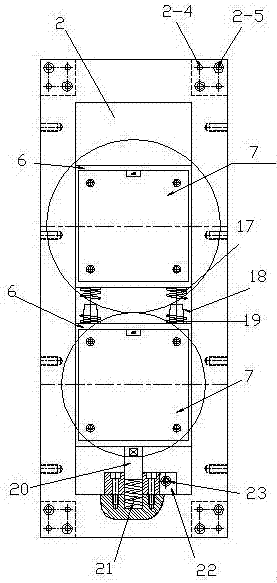

[0082] Such as figure 1 A rotary rolling die-cutting device shown, outer frame 1, inner frame 2, upper knife roller 3, lower knife roller 4, multiple sliding devices, pressure device, pressure relief device, position adjustment device, limit device , as well as the roller body cleaning device and the servo transmission device, the upper cutter roller 3 and the lower cutter roller 4 are arranged inside the inner frame, the sliding devices are respectively arranged at the two ends of the upper cutter roller 3 and the lower cutter roller 4, and the pressure relief device is arranged on Between the two sliding devices, the position adjustment device is set under the two ends of the lower knife roller, the servo transmission device is fixed on the outside of the inner frame, and the pressure device is fixed on the outer frame, wherein:

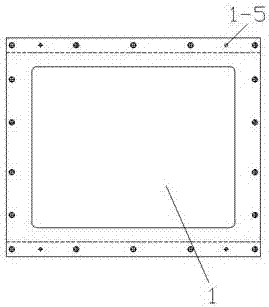

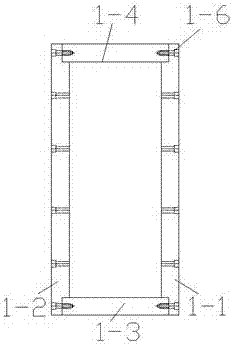

[0083] Outer frame 1 includes outer frame side plate a1-1, outer frame side plate b1-2, outer frame bottom plate 1-3, outer frame top plate 1-4, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com