Energy-saving automatic stereoscopic warehouse

A three-dimensional warehouse, three-dimensional technology, applied in conveyors, storage devices, transportation and packaging, etc., can solve problems such as a large amount of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

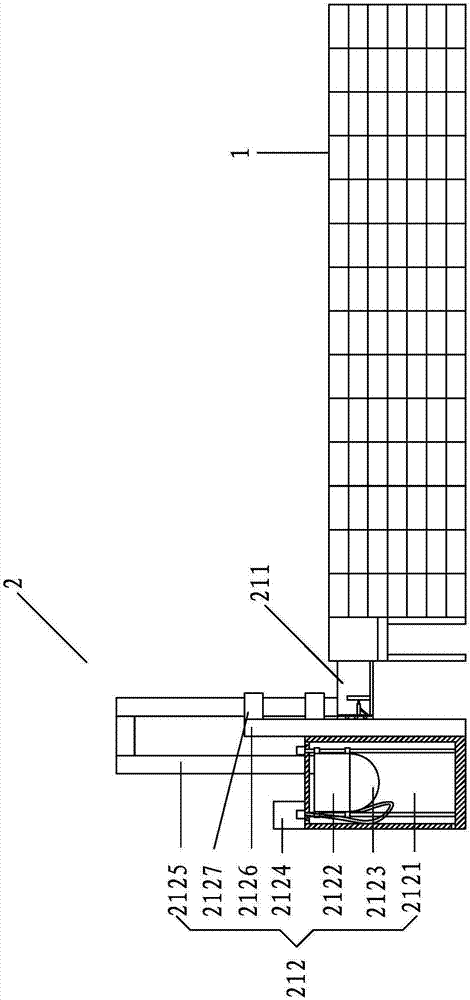

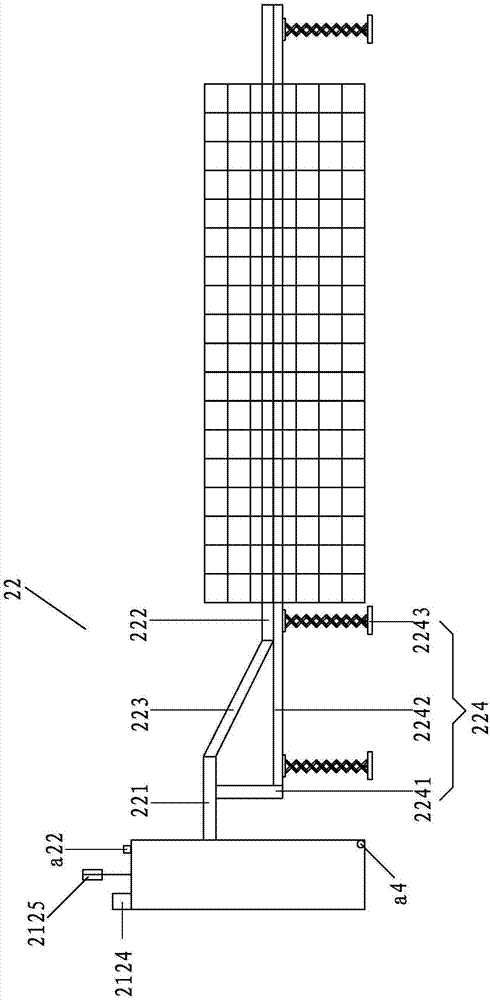

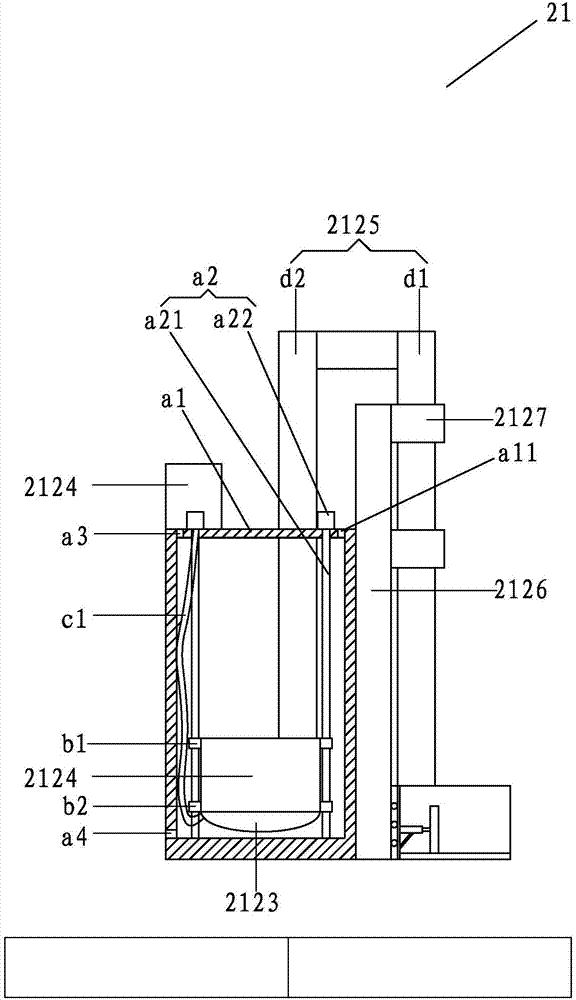

[0052] A kind of energy-saving automatic three-dimensional warehouse of the present invention, as Figure 1-5 As shown, it includes a three-dimensional storage bin 1 and a delivery mechanism 2 for transporting goods to the three-dimensional storage bin 1 .

[0053] The three-dimensional storage warehouse 1 includes a support frame and a multi-layer storage layer placed on the support frame and arranged up and down, and the storage layer includes a plurality of storage channels arranged horizontally and parallel to each other;

[0054] Cargo transport mechanism 2 is located at the incoming end of three-dimensional storage warehouse 1; cargo transport mechanism 2 includes a lifting device 21 that lifts the goods to the corresponding storage layer, and a conveying slide 22 that can be lifted to the corresponding storage layer for the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com