Construction method of a pile machine

A construction method and the technology of a pile machine, which are applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve hidden dangers of operation safety, increased construction costs, and difficulties in ensuring the vertical accuracy and straightness accuracy requirements of implanted piles And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

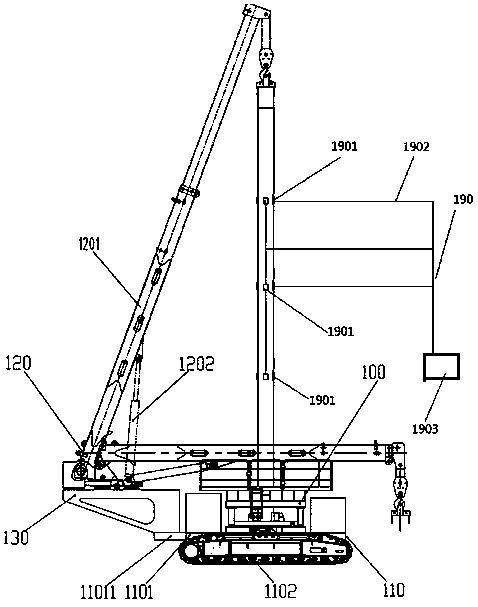

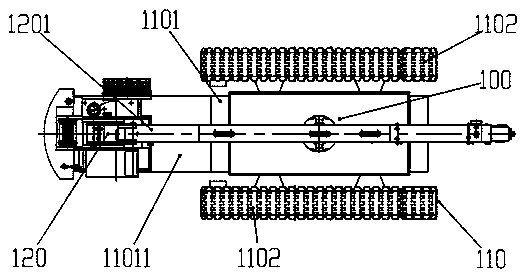

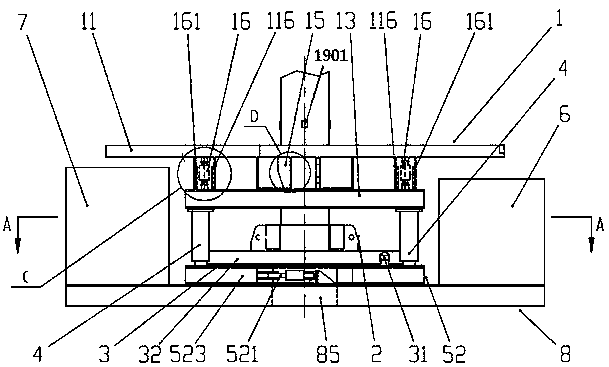

[0019] Such as Figure 1-8 As shown, a pile planting machine includes: a traveling mechanism 110, a lifting mechanism 120, a support frame 130, a clamping mechanism 100 and a pile body monitoring system 190; wherein: the clamping mechanism 100 includes an upper frame 1, a lower clamping mechanism 2. Slewing mechanism 3, fine-tuning mechanism 52, lower frame 8, vertical jacking cylinder 4, hydraulic system 6 and electric welding machine warehouse 7 containing gas storage cylinder, wire feeding device and carbon dioxide gas shielded automatic welding machine, in which: upper machine The frame 1 includes a working platform 11 with a flange inner ring 112 and a fixed sleeve 116, a plurality of clamping wedges 15, a clamping ring 12, an upper chassis 13 with a sleeve 161, an upper clamping cylinder 16 and a connecting plate 17 The lower clamping mechanism 2 includes a lower clamping oil cylinder 21, an arc ring 23, two symmetrically arranged lower clamping arms 22, 22' and a blocki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com