A method for controlling the overflow opening of steam turbine supplementary steam valve

A technology for opening control and supplementary valves, applied in mechanical equipment, engine components, machines/engines, etc., it can solve the problems of inability to supply heat, and the unit cannot carry full load and rise, so as to improve thermal efficiency, ensure full load, and improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

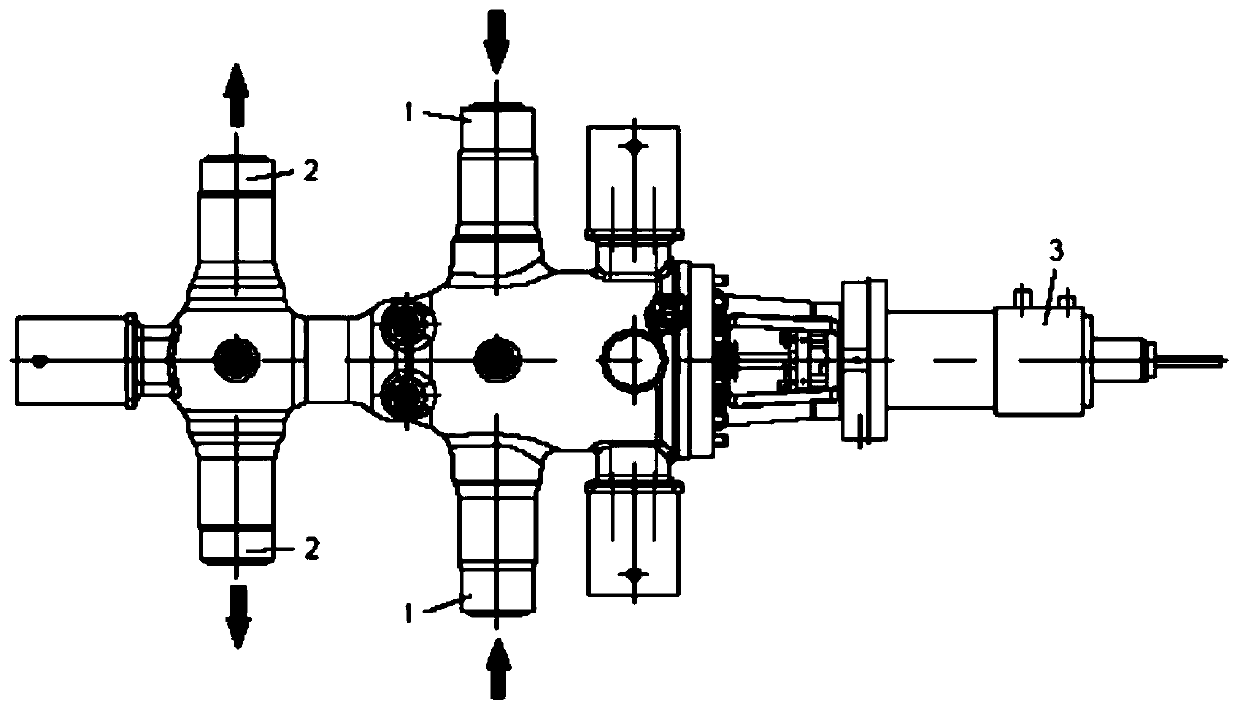

[0025] Schematic diagram of the gas supply valve structure of the steam turbine figure 1 shown. The supplementary steam technology is a unique technology of Siemens. It starts from a certain working condition to draw some new steam (5-10% of the rated steam intake) from behind the main steam valve and in front of the main regulating valve. After the steam temperature is reduced by about 30°C, it enters the space behind the high-pressure fifth-stage rotor blade, and the mainstream is mixed with this steam, which is a measure that continues to expand and do work in subsequent stages. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com