Pipeline device for slag lock hopper and coal water slurry gasification slag removal system

A slag lock and pipeline technology, applied in the field of coal-water slurry gasification project equipment, can solve problems such as accidents, equipment instability, pipeline ruptures, etc., and achieve the effects of less turning, stable structure, and uniform stress on pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

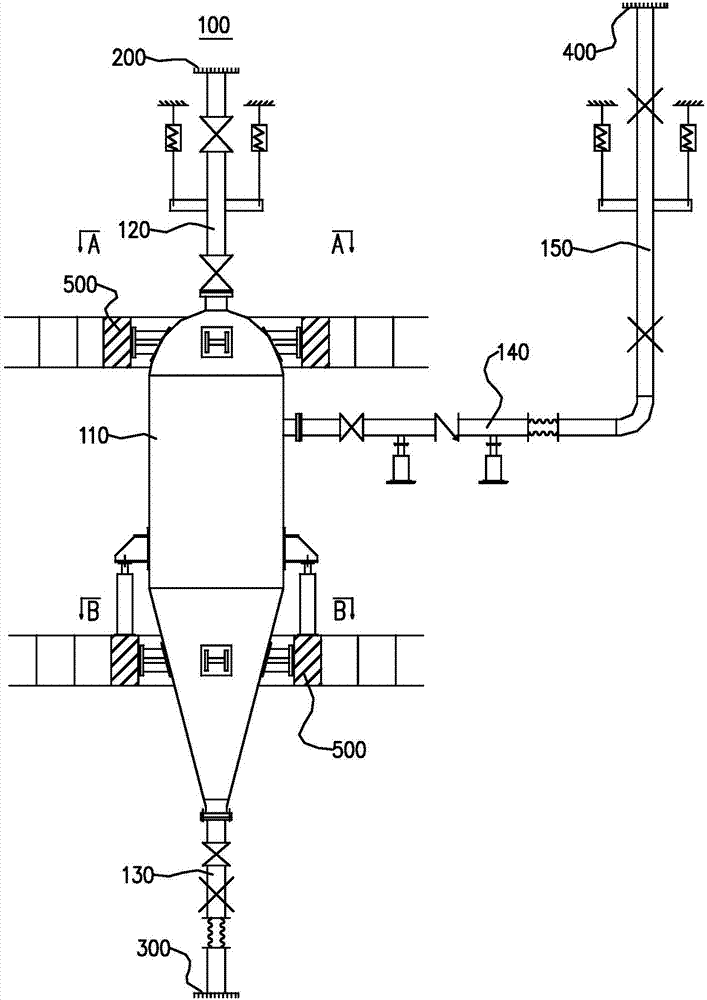

[0044] see figure 1 , this embodiment provides a slag lock hopper pipeline device 100 , including a slag lock hopper 110 , a first vertical pipe section 120 , a second vertical pipe section 130 , a horizontal pipe section 140 and a third vertical pipe section 150 .

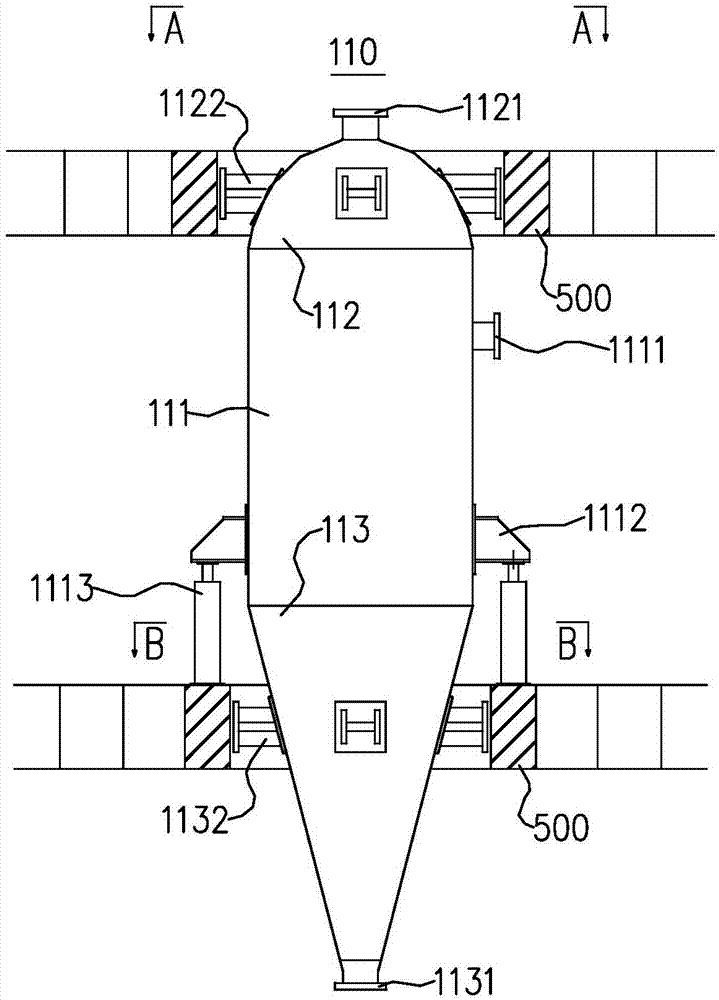

[0045] see figure 2 , The slag lock bucket 110 includes a central cylinder 111 , an upper head 112 and a lower head 113 . The middle cylinder 111 is provided with a water inlet. The upper head 112 is arranged on the top of the middle cylinder 111 , and the top of the upper head 112 is provided with a slag inlet 1121 . The lower head 113 is arranged at the bottom of the middle cylinder 111 , and the bottom of the lower head 113 is provided with a slag outlet 1131 .

[0046] The slag lock bucket 110 is installed and fixed by cooperating with the civil construction beam 500 through the upper head 112 and the lower head 113 respectively.

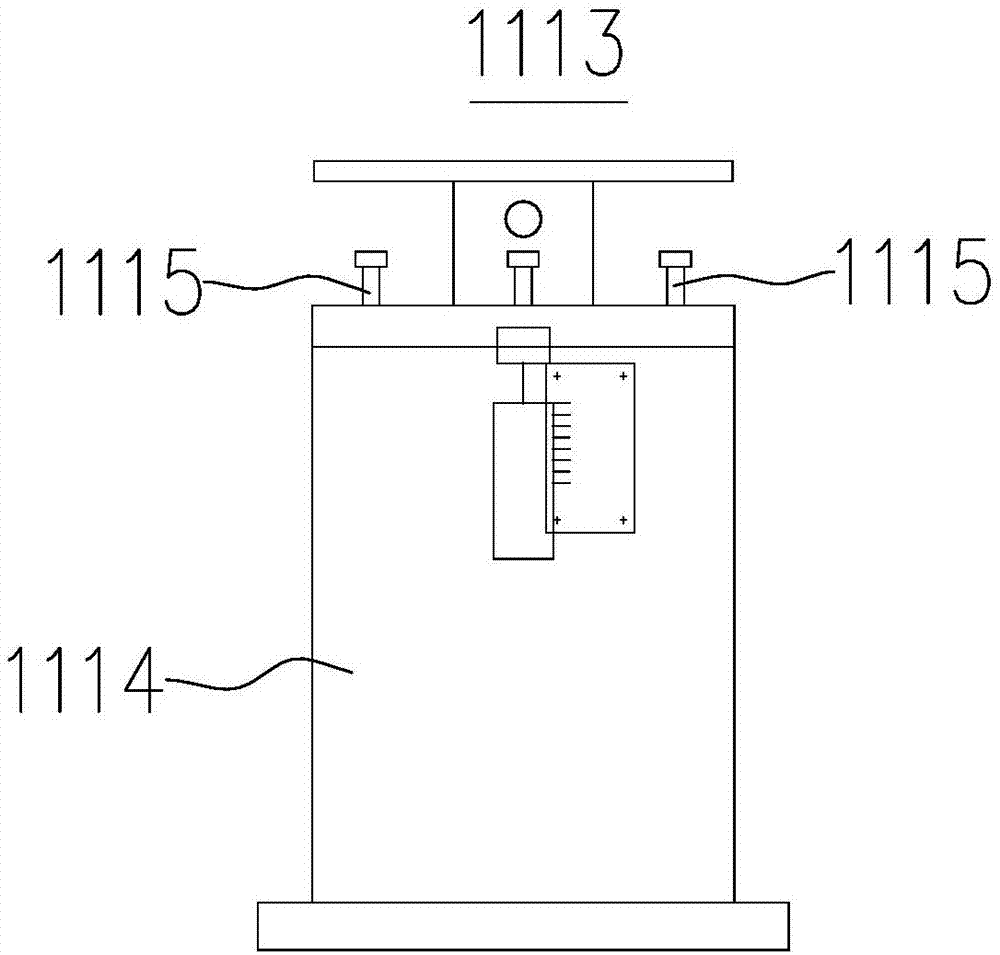

[0047] In this embodiment, four lugs 1112 are provided at the end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com