Cooling device of transformer substation power transmission line

A cooling device and transmission line technology, applied in temperature control, non-electric variable control, instruments, etc., can solve the problems of increased energy consumption, inability to detect the temperature of transmission lines, long length of transmission lines, etc., to reduce use and energy consumption , increase the heat dissipation effect, the effect of low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further detailed explanation through specific implementation mode below:

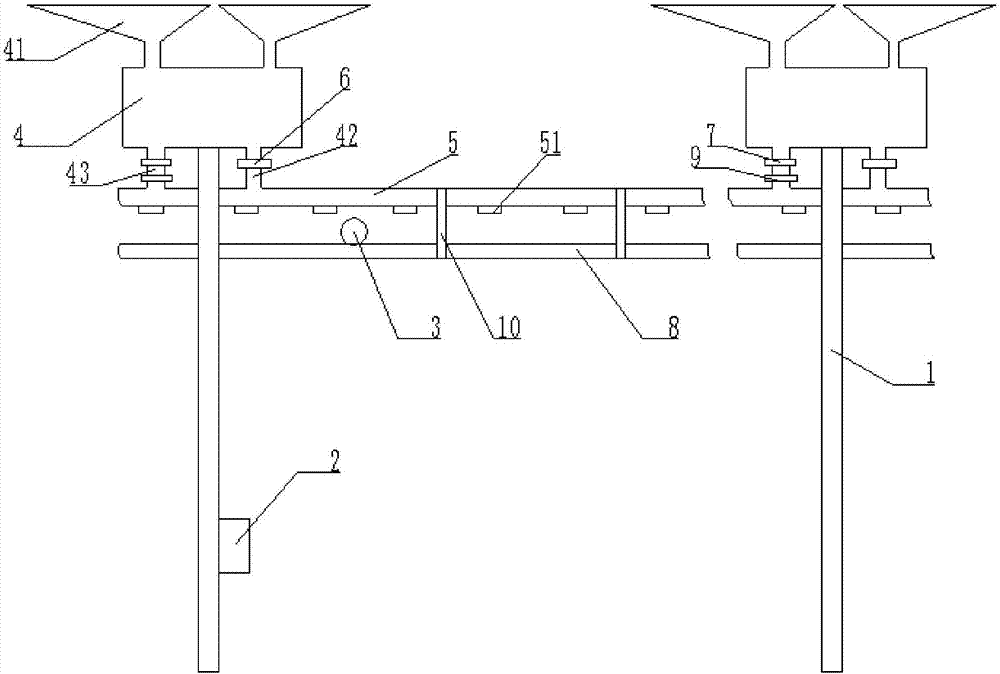

[0020] The reference signs in the drawings of the description include: electric pole 1, microcontroller 2, temperature sensor 3, insulated water storage tank 4, rainwater receiving tank 41, water inlet conduit 42, water outlet conduit 43, water pipe 5, sprinkler head 51, solenoid valve 6. One-way valve 7, wire 8, water pump 9, wire clamp 10.

[0021] Such as figure 1 Shown is a schematic diagram of the structure of the power line cooling device of the substation, including a power supply and a microcontroller 2, wherein the power supply is a solar power generation device, which is pollution-free and has low operating costs. An insulating water storage tank 4 is fixedly installed on the top of the pole 1, and two rainwater receiving tanks 41 are fixedly installed above the insulating water storage tank 4, and the rainwater receiving tank 41 is a funnel shape, which increases the area for receivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com