Recognition method for operating state of industrial equipment and server

A technology of industrial equipment and operating status, applied in the field of information, can solve the problems of cumbersome operation process, and achieve the effect of simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

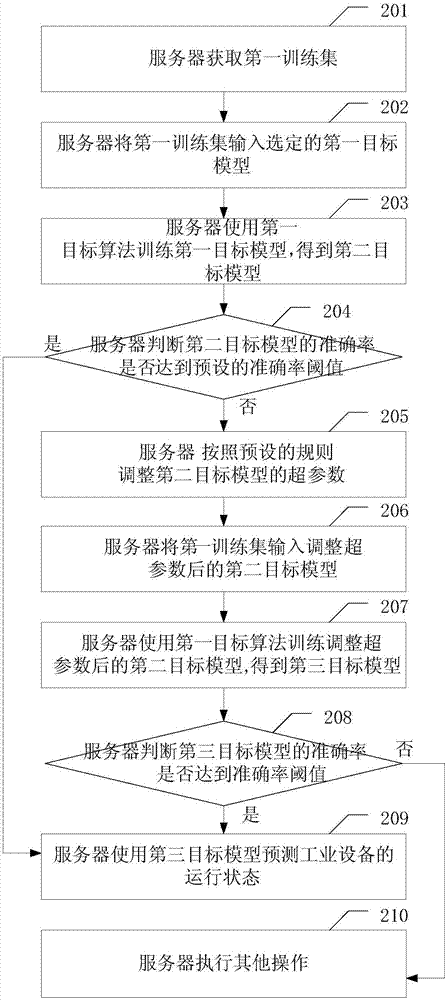

[0102] The embodiment of the present application provides a method for identifying the operating state of industrial equipment and a server. For the second target model that does not reach the preset accuracy threshold, the server adjusts the parameters of the second target model according to the preset rules. Compared with the current There are techniques that require human adjustment, which simplifies the operation process.

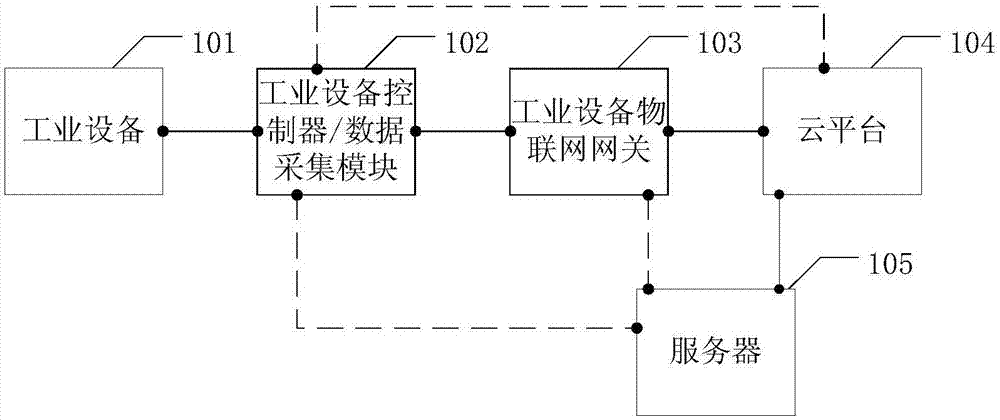

[0103] see figure 1 , the system architecture for identifying the operating status of industrial equipment includes industrial equipment 101 , industrial equipment controller / data acquisition module 102 , industrial equipment IoT gateway 103 , cloud platform 104 and server 105 . As a controller, the industrial equipment controller can include sensors and other units with functions such as data transmission control. The data acquisition module can include other units such as sensors and controllers. It is a communication module based on the remote data a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com