Motor counter electromotive force sampling system and method

A technology of motor current sampling and back electromotive force, which is applied in the field of wire feeding speed regulation system and motor back electromotive force sampling system, can solve the problems affecting the accuracy of back electromotive force sampling, reduce control complexity, ensure sampling accuracy, and improve sampling The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

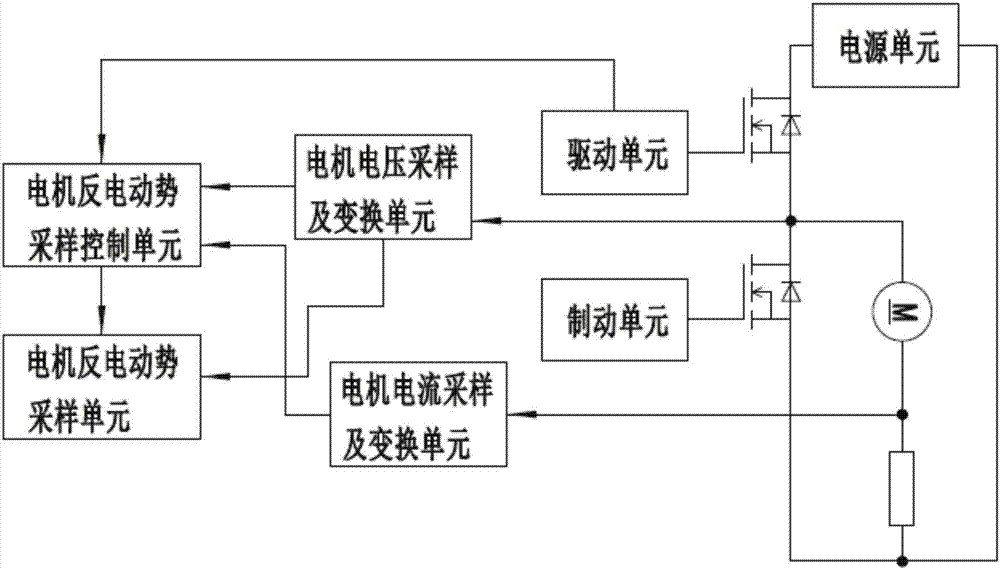

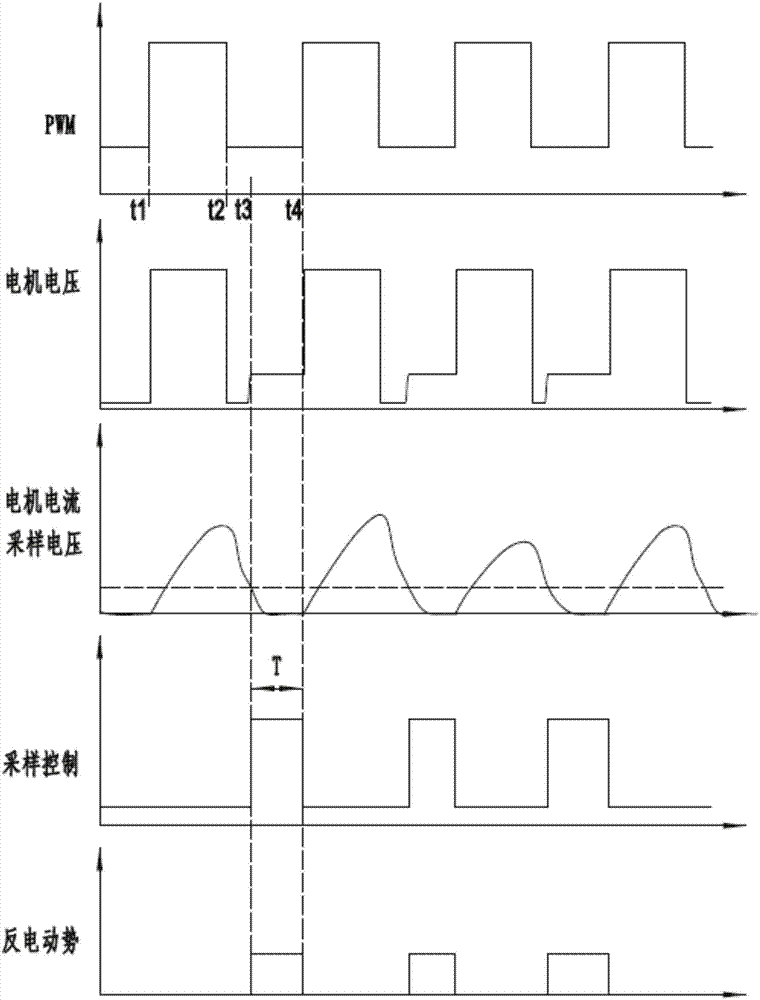

[0030] see figure 2 The motor back electromotive force sampling system includes a motor, a motor back electromotive force sampling unit and a motor back electromotive force sampling control unit connected to the motor back electromotive force sampling unit, the motor back electromotive force sampling control unit acquires the working state data of the motor, and According to the acquired working state data, the acquisition state of the motor back electromotive force sampling unit is controlled, so that the motor back electromotive force sampling unit samples the back electromotive force of the motor within the time period when the motor generates back electromotive force.

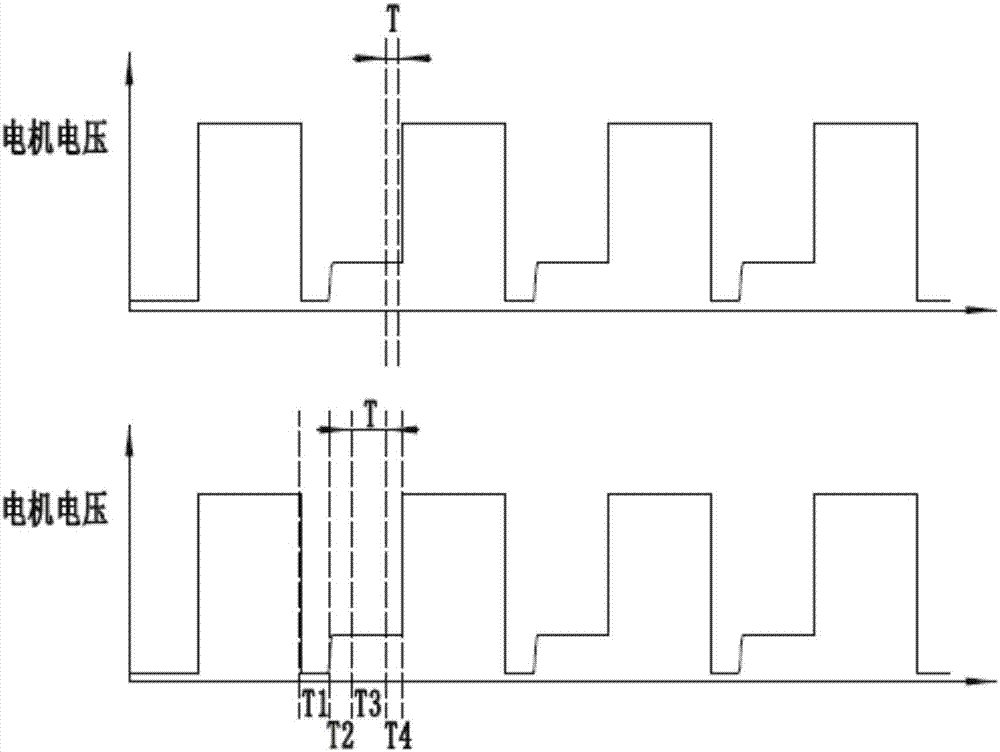

[0031] In a preferred embodiment, the motor back electromotive force sampling control unit includes three input terminals, and obtains the PWM driving state of the motor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com