Green hedge pruning machine

A technology for a hedge trimmer and a hedge, applied in the field of garden machinery, can solve the problems of high labor intensity, dull effect, scratched branches, etc. for operators, and achieve the effects of reducing labor intensity, avoiding efficiency, and beautiful green belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

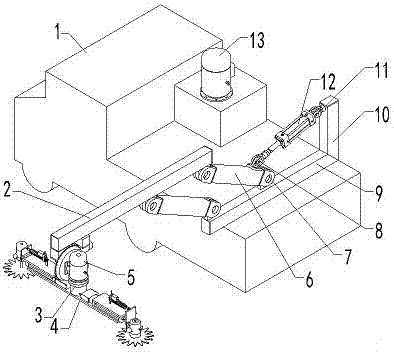

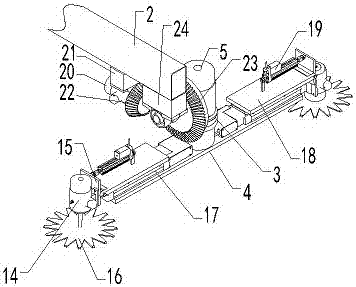

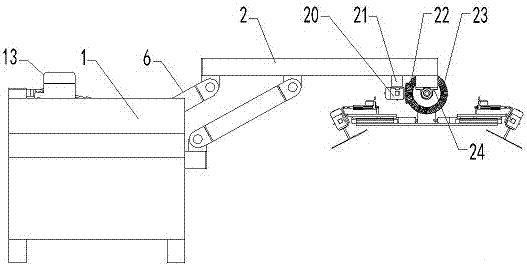

[0025] Examples such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a hedge trimmer includes a tractor 1, a cantilever device parallel to the tractor 1 is provided near the rear end of the tractor 1, one end of the cantilever device is located on one side of the tractor 1, and a cantilever device is installed. The multi-angle trimming device is used to trim hedges. The other end of the cantilever device is connected to the tractor 1 through the adjustment device. The height position of the trimming device and the multi-angle adjustment of the trimming device are adjusted by the cantilever device to trim hedges of different shapes.

[0026] The cantilever device includes a cantilever rod 2 arranged horizontally, and two connecting rods 6 are arranged in translation at a certain distance below one end of the cantilever rod 2 close to the tractor 1, and the two connecting rods 6 are respectively connected to the cantilever rod 2 through the hinge shaft 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com