A coaxial cylindrical dbd reactor with adjustable eccentricity

A reactor, eccentricity technology, applied in chemical instruments and methods, chemical/physical/physical-chemical processes, chemical/physical/physical-chemical processes of energy application, etc. Simple and convenient effects of electrodes and barrier media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

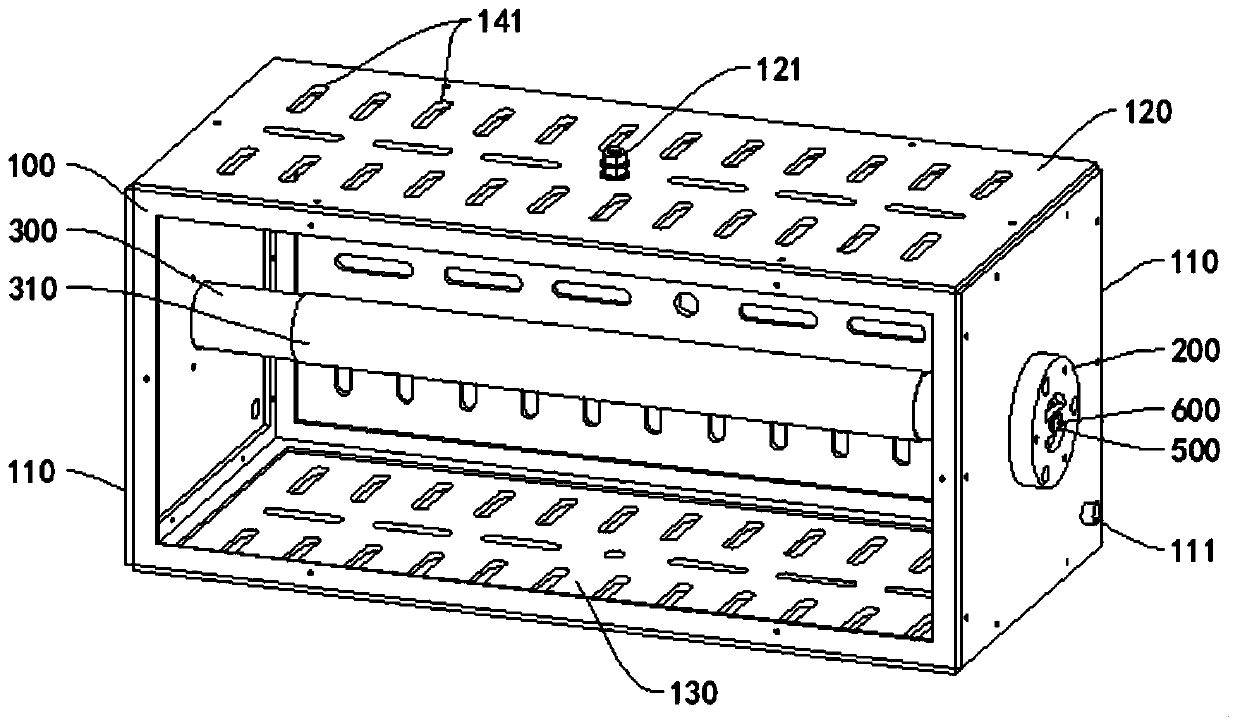

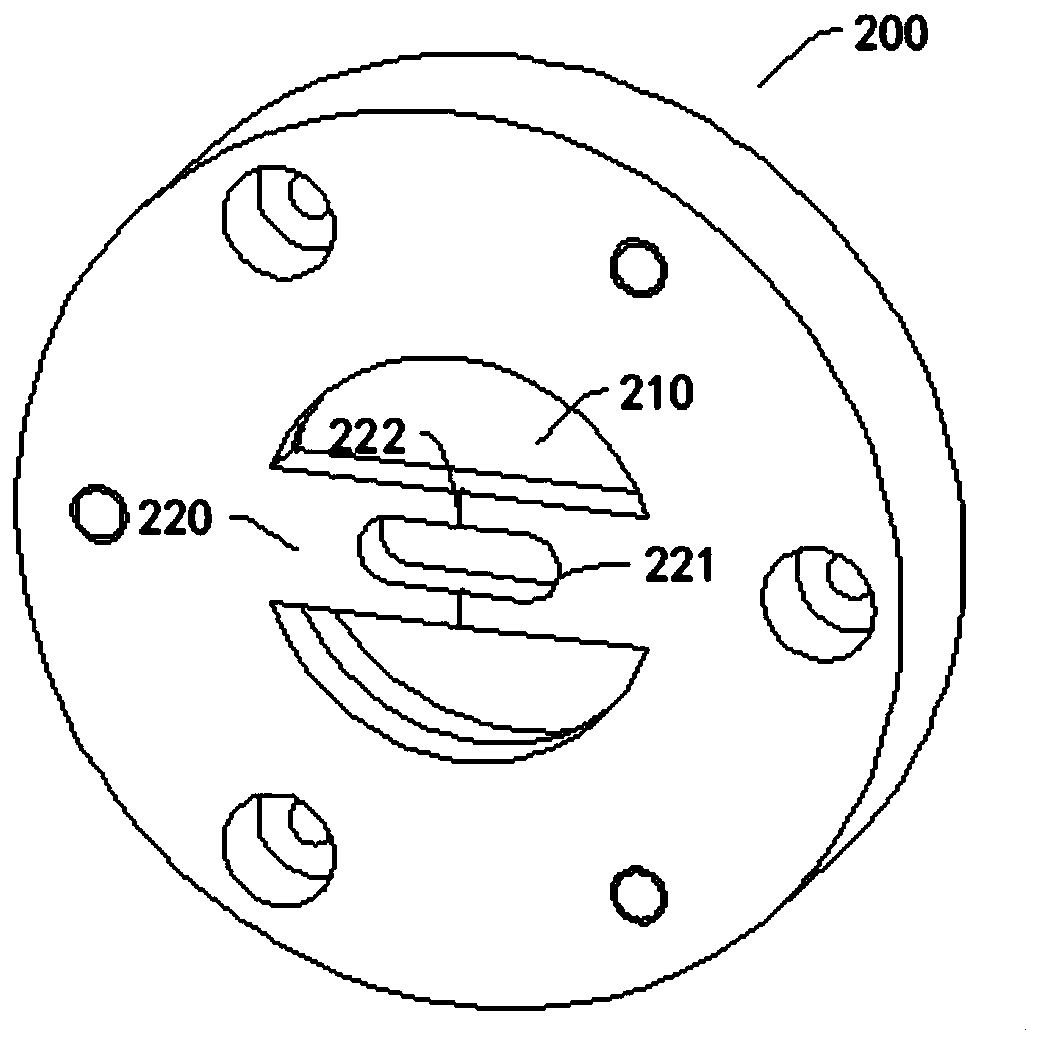

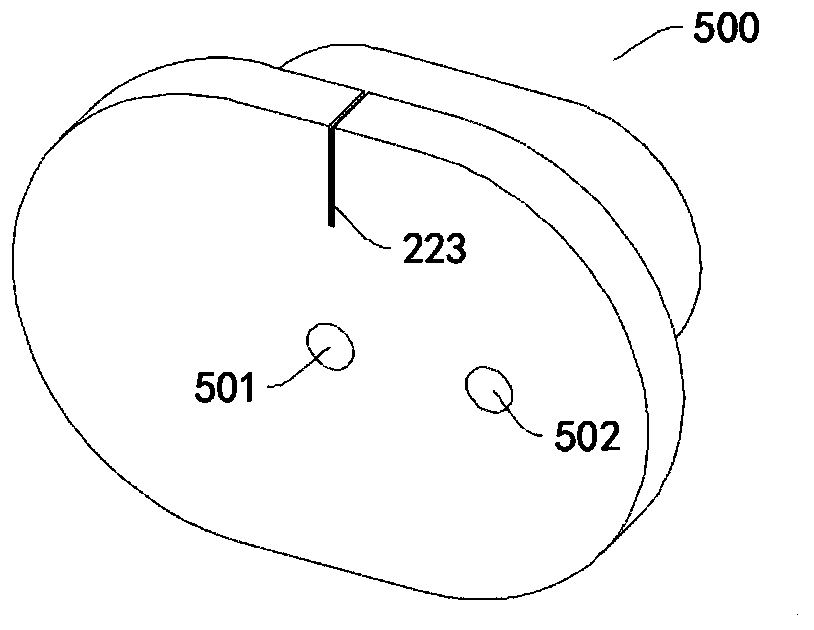

[0027] Embodiment 1: A coaxial cylindrical DBD reactor with adjustable eccentricity, constituted as figure 1 As shown, including the frame body 100, the two ends of the frame body 100 are symmetrically provided with a fixed plate 110, the fixed plate 110 is provided with a fixed cover 200, a blocking medium 300 is provided between the two fixed covers 200, and the fixed cover 200 is provided with The stepped hole 210, the stepped hole 210 includes a large hole 211 located inside the fixed cover 200 and a small hole 212 located outside the fixed cover 200, the two ends of the blocking medium 300 are fixed in the large hole 211; the fixed cover 200 is provided with a horizontal The crossbeam 220 that wears aperture 212, is provided with straight groove 221 in the middle of crossbeam 220; The straight groove 221 of a fixed cover 200 is provided with adjustment base 400, is provided with adjustment screw 410 in the middle of adjustment base 400, and the small end of adjustment scre...

Embodiment 2

[0034] Embodiment two: if Figure 6 As shown, the barrier medium 300 is provided with a columnar internal electrode 700, and the center of the two ends of the columnar internal electrode 700 is provided with a screw hole 701, and the straight grooves 221 of the two fixed covers 200 are provided with plug screws 240. The screw 240 is connected with the screw hole 701 .

[0035] In this embodiment, the structure of the frame part is the same as that of Embodiment 1, and the filament internal electrode 600 is replaced by a columnar internal electrode 700, and the two ends of the columnar internal electrode 700 are screwed through the plug screws 240 in the straight groove 221. fixed.

[0036] The columnar inner electrode 700 is not limited to a cylinder, as long as both ends can be threaded.

[0037] The head of the plug screw 240 is provided with a third scoring line 241 . The advantage of using the plug screw 240 is that the plug screw 240 itself has a high geometric accurac...

Embodiment 3

[0039] Embodiment three: as Figure 7 As shown, the large hole 211 is provided with a seat 320, and the seat 320 is provided with a secondary stepped hole 321, and the two ends of the barrier medium 300 are set in the secondary stepped hole 321.

[0040] In this embodiment, both ends of the barrier medium 300 are fixed on the seat 320 , and the seat 320 is fixed on the fixed cover 200 . The inner diameter of the auxiliary stepped hole 321 on the seat 320 changes with the diameter of the barrier medium 300 , but the outer diameter of the seat 320 is constant. Therefore, by replacing the supporting seat 320 and the barrier medium 300 in the device of this embodiment, it is very convenient to study the influence of the diameter of the barrier medium 300 on the dielectric barrier discharge. At the same time, what is changed in this embodiment is the barrier medium, which does not conflict with the changed inner electrodes in the first and second embodiments.

[0041] In addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com