An Eccentric Adjusting Vibration Damping Device for Non-contact Sealing

A technology of eccentric adjustment and vibration damping device, which is applied in the direction of shock absorbers, spring/shock absorber design features, shock absorbers, etc., can solve the problem of increasing effective medium loss and waste of power energy, and cannot solve the problem of rotor eccentricity. To reduce or eliminate the problem of unequal pressure, reduce or eliminate rotor eccentricity, reduce or eliminate eccentricity, and weaken the effect of fluid excitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

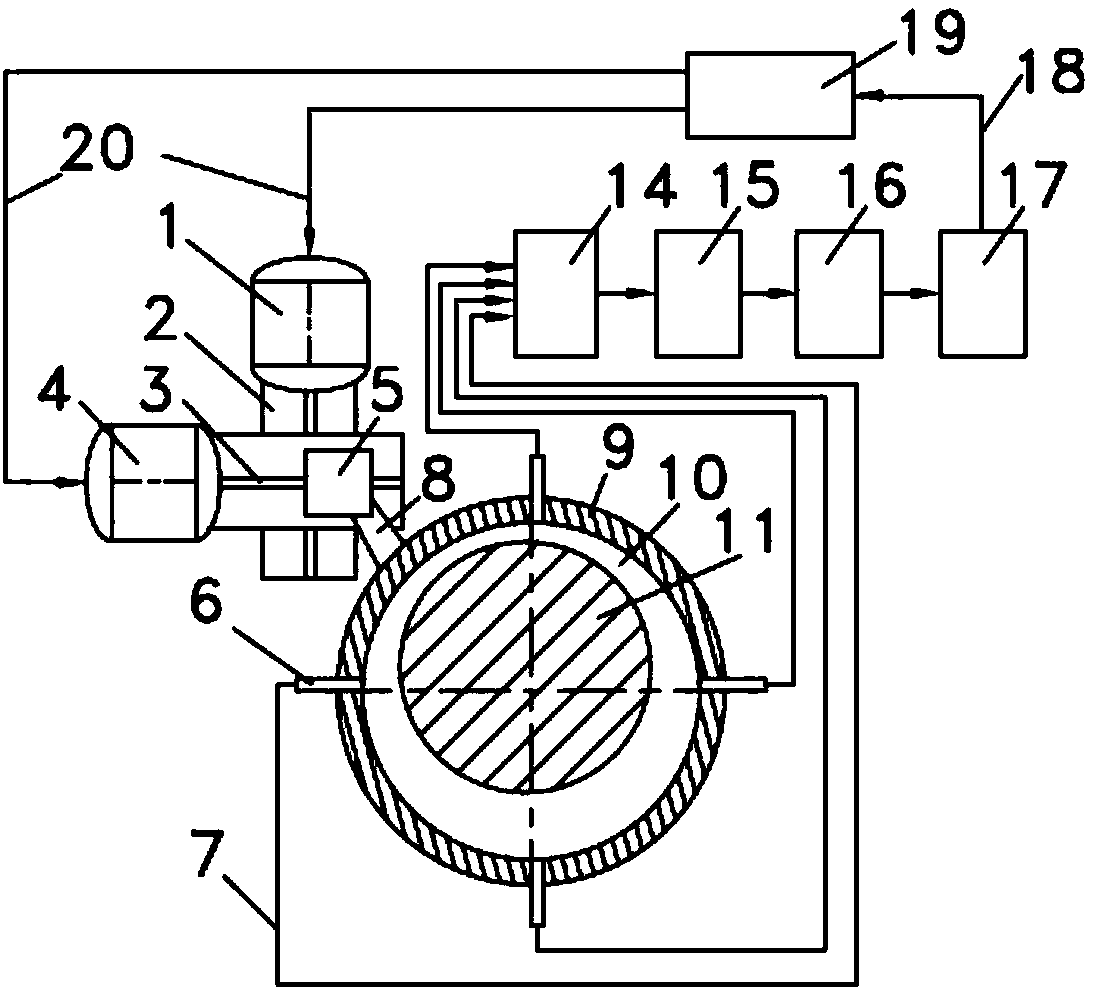

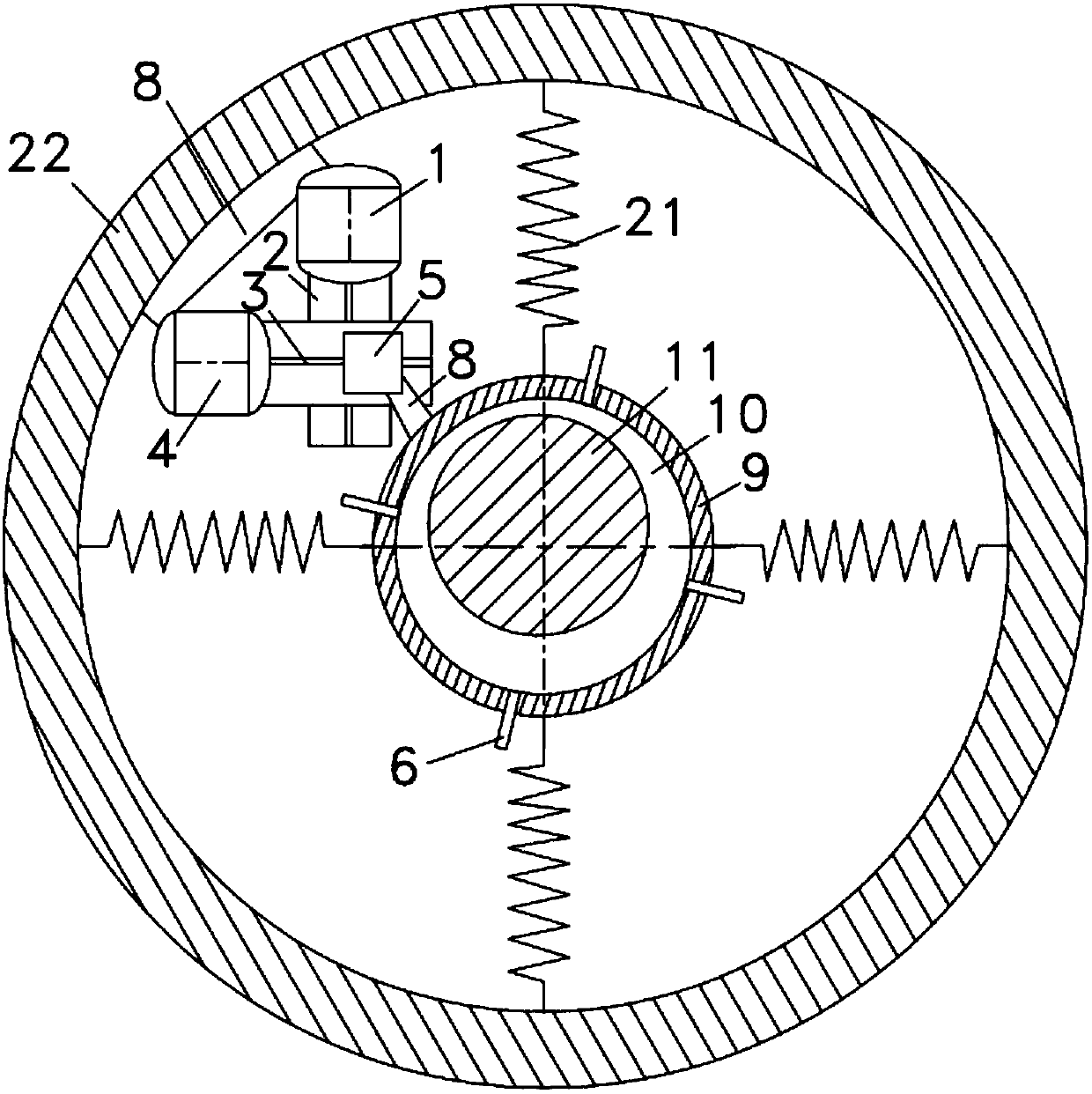

[0038] The sealing eccentricity adjustment vibration damping device of the present invention will be described in detail below in conjunction with the accompanying drawings.

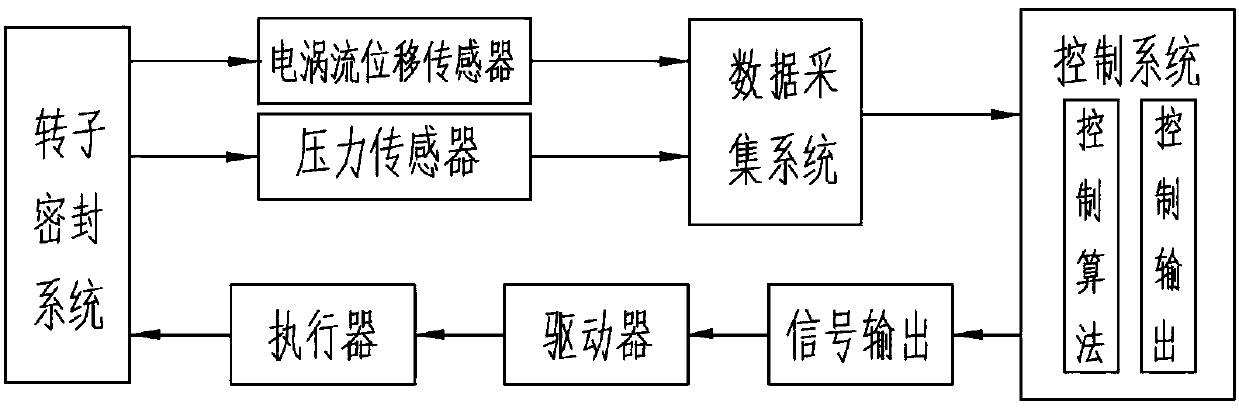

[0039] An eccentric adjustment damping device for non-contact sealing, which includes two parts: a real-time signal detection and analysis control system and an execution system.

[0040] The real-time signal detection analysis control system is composed of a pressure sensor 6 , an eddy current displacement sensor 12 , a connection terminal 14 , a signal conditioning module 15 , a data acquisition card 16 and a computer 17 .

[0041] The number of pressure sensors 6 is four to six, and the number of eddy current displacement sensors 12 is one to two.

[0042] The pressure sensor 6 and the eddy current displacement sensor 12 are connected to the computer 17 through wires; the pressure sensor 6 is screwed tightly on the sealing stator 9, and is evenly arranged along the circumferential direction, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com