A mine multi-purpose vertical shaft pipeline material conveying system

A conveying system and multi-purpose technology, which can be used in fillings, mining equipment, underground transportation, etc., can solve the problems of high excavation cost, long construction period, increased mine burden, etc., to achieve strong adaptability, reduce production costs, and easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings. The following embodiments are only used to explain the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

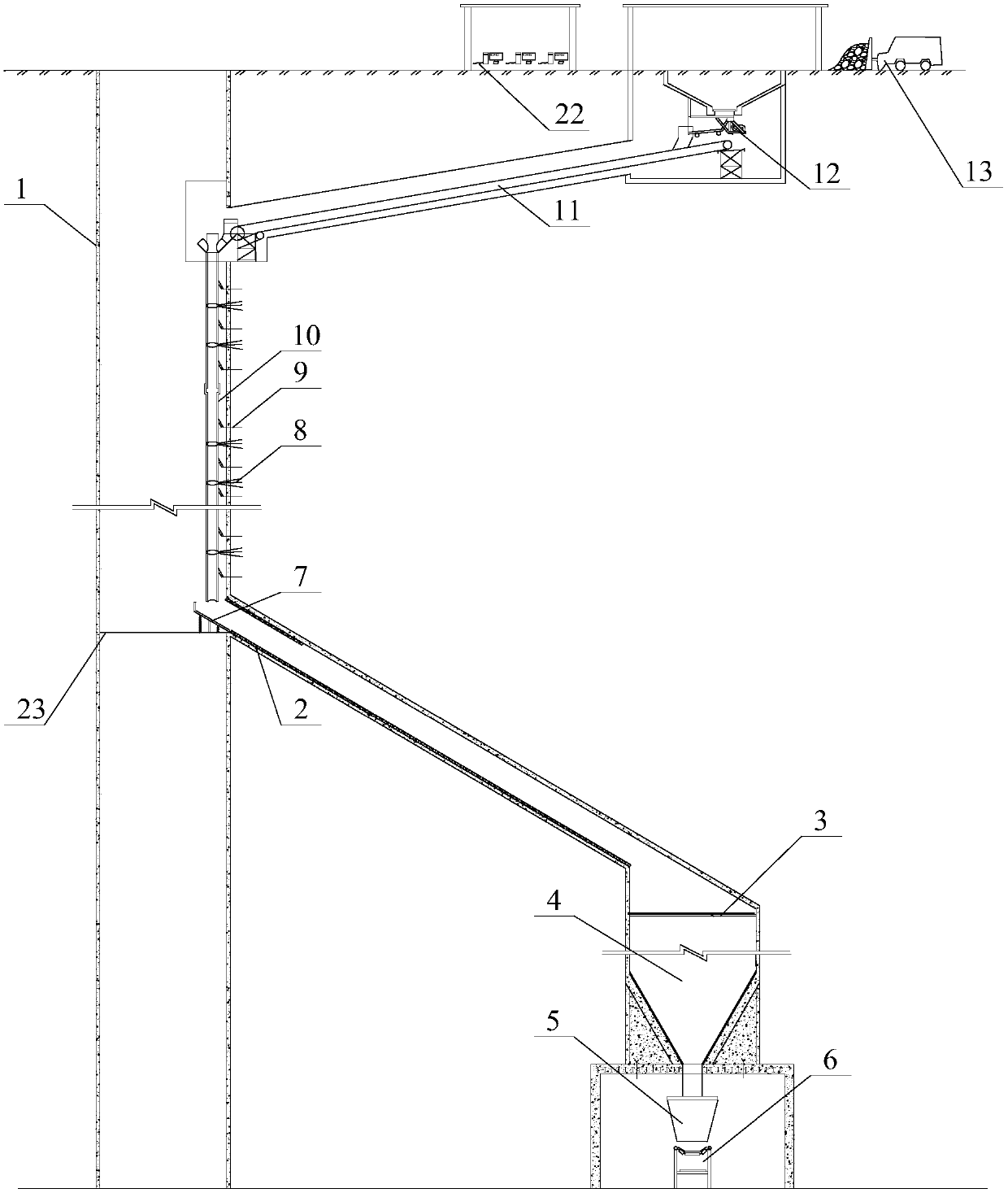

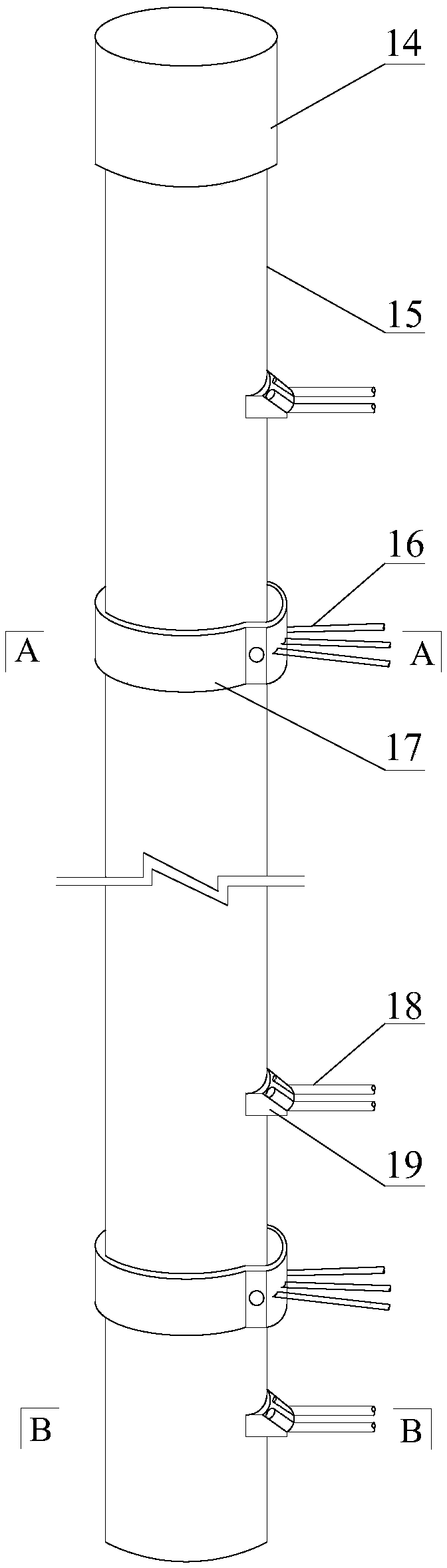

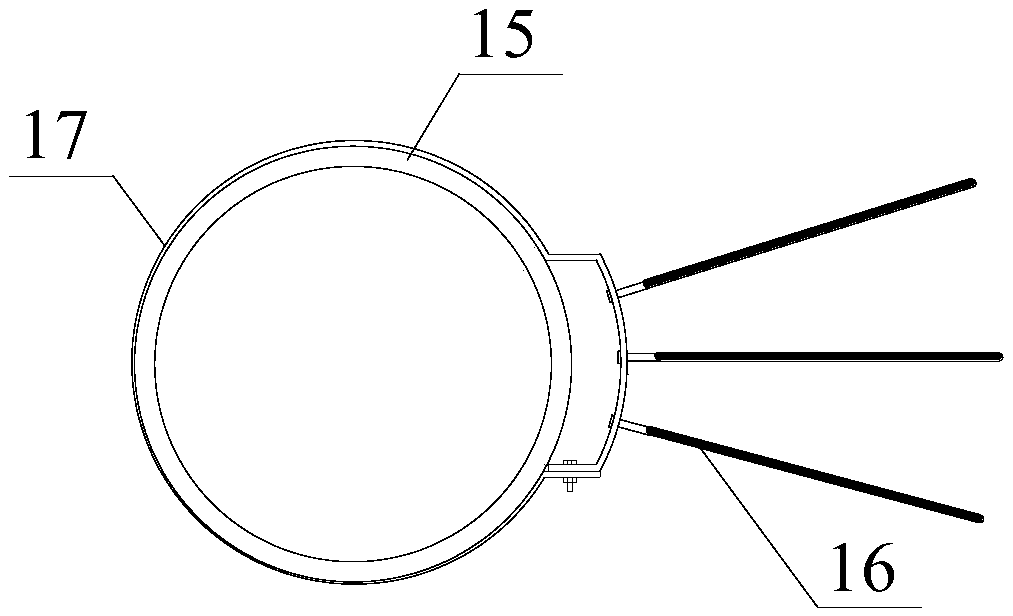

[0024] Such as Figure 1 to Figure 6 As shown, the system includes an uphole material transportation system, a vertical pipeline transportation system, a material retarding system, an anti-overflow storage system, an underground material transportation system, and a pipeline settlement early warning system modified on the original functional vertical shaft.

[0025] The modified in-well material transportation system includes a trackless feeder 13, a ground feeder 12, and an in-well belt conveyor 11. The trackless vehicle 13 transports the bulk filling materials to the ground feeder 12 in the receiving pit, and It is transported to the wear-resistant vertical pipeline 10 by the uphole conveyor belt c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com