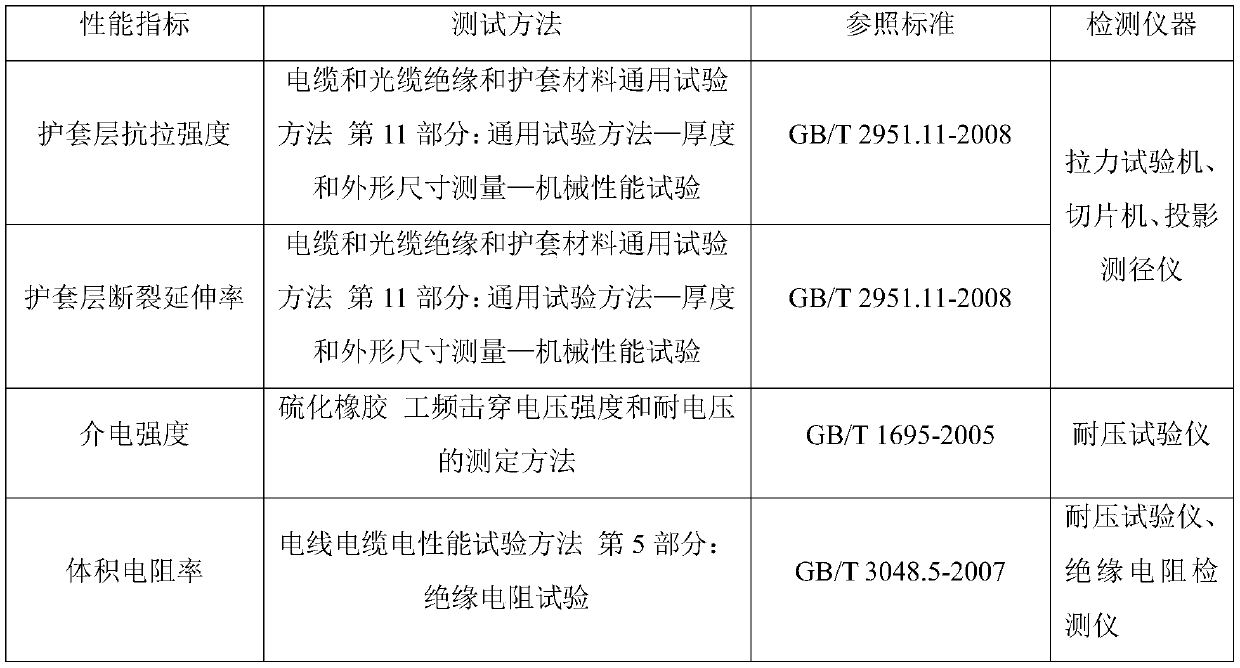

Sheath material, fire-resistant flame-retardant cable and preparation method thereof

A fire-retardant, flame-retardant, sheathing material technology, applied in rubber insulators, organic insulators, etc., can solve the problems of high cost, poor installation and laying performance, complex cable structure, etc., and achieve the effect of excellent insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Use annealed copper material to make stranded conductors;

[0025] 2. Use synthetic mica tape for multi-layer overlapping wrapping on the outside of the stranded conductor. The wrapping angle of the mica tape is 28°, the overlap rate is 25%, and the heat-resistant cross-linked polyethylene insulation layer is extruded on the outside of the mica. , The core is made;

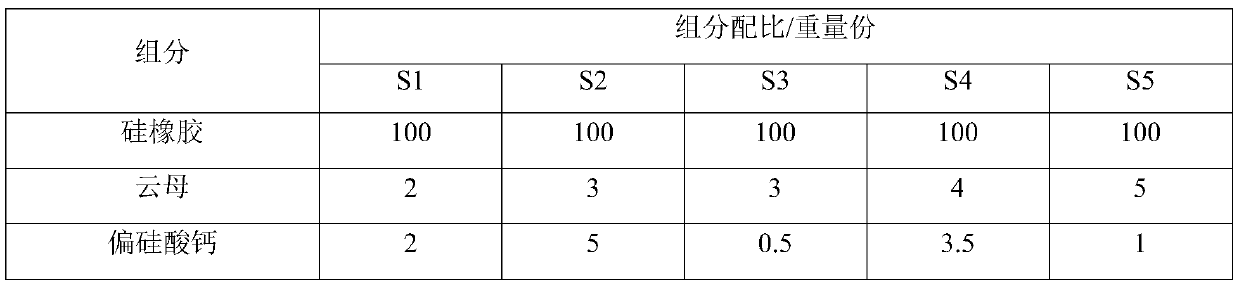

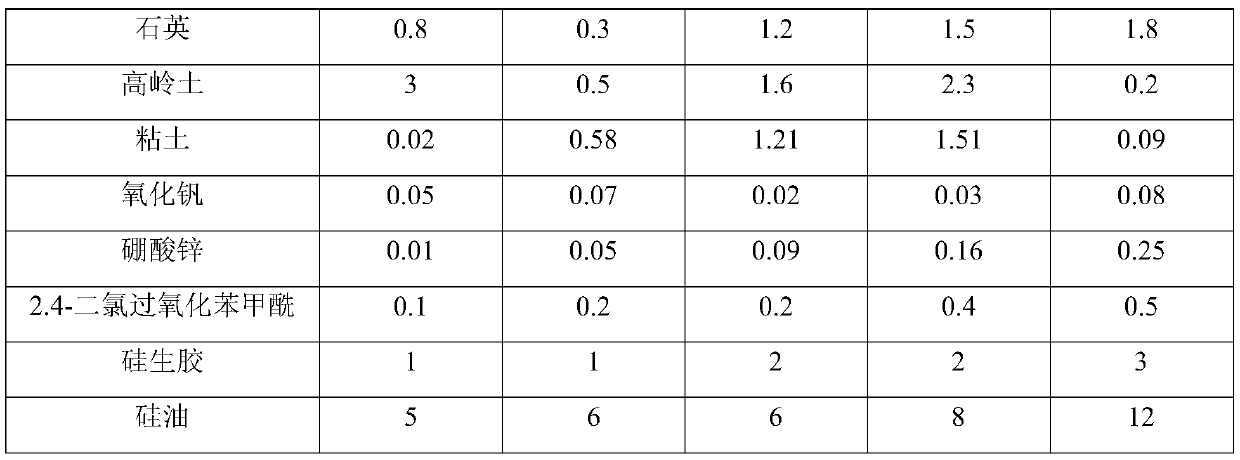

[0026] 3. According to parts by weight, the following components: 100 parts by weight of silicone rubber, 2 parts by weight of mica (average particle size 15-25μm), 2 parts by weight of calcium metasilicate, 0.8 parts by weight of quartz, 3 parts by weight of kaolin, 0.02 parts by weight of clay Parts by weight, 0.05 parts by weight of vanadium oxide, 0.01 parts by weight of zinc borate, 0.1 parts by weight of 2.4-dichlorobenzoyl peroxide, 1 part by weight of raw silicone rubber, and 5 parts by weight of silicone oil, for compounding;

[0027] 4. The silicone rubber is smelted and mixed thoroughly with other c...

Embodiment 2

[0030] 1. Use annealed copper material to make stranded conductors;

[0031] 2. The synthetic mica tape is used for multi-layer overlapping wrapping on the outside of the stranded conductor. The wrapping angle of the mica tape is 30°, the overlap rate is 15%, and the heat-resistant cross-linked polyethylene insulation layer is extruded on the outside of the mica , The core is made;

[0032] 3. According to parts by weight, the following components: 100 parts by weight of silicone rubber, 3 parts by weight of mica (average particle size 15-25μm), 5 parts by weight of calcium metasilicate, 0.3 parts by weight of quartz, 0.5 parts by weight of kaolin, 0.58 parts by weight of clay Parts by weight, 0.07 parts by weight of vanadium oxide, 0.05 parts by weight of zinc borate, 0.2 parts by weight of 2.4-dichlorobenzoyl peroxide, 1 part by weight of raw silicone rubber, and 6 parts by weight of silicone oil, for compounding;

[0033] 4. The silicone rubber is smelted and mixed thoroughly wit...

Embodiment 3

[0036] 1. Use annealed copper material to make stranded conductors;

[0037] 2. Adopt synthetic mica tape for multi-layer overlapping wrapping on the outside of the stranded conductor. The wrapping angle of the mica tape is 35°, the overlap rate is 30%, and the heat-resistant cross-linked polyethylene insulation layer is extruded on the outside of the mica , The core is made;

[0038] 3. According to parts by weight, the following components: 100 parts by weight of silicone rubber, 3 parts by weight of mica (average particle size of 15-25μm), 0.5 parts by weight of calcium metasilicate, 1.2 parts by weight of quartz, 1.6 parts by weight of kaolin, 1.21 parts by weight of clay Parts by weight, 0.02 parts by weight of vanadium oxide, 0.09 parts by weight of zinc borate, 0.2 parts by weight of 2.4-dichlorobenzoyl peroxide, 2 parts by weight of raw silicone rubber, and 6 parts by weight of silicone oil, for compounding;

[0039] 4. The silicone rubber is smelted and mixed thoroughly wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com