Pressure adjustable reciprocating synchronization alternating current and direct current electromagnetic pump

A reciprocating and synchronous handover technology, applied in the field of electromagnetic pumps, can solve problems such as energy loss, inability to adjust, and energy waste, and achieve good social and economic benefits, automatic adjustment of output pressure, and novel and unique structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

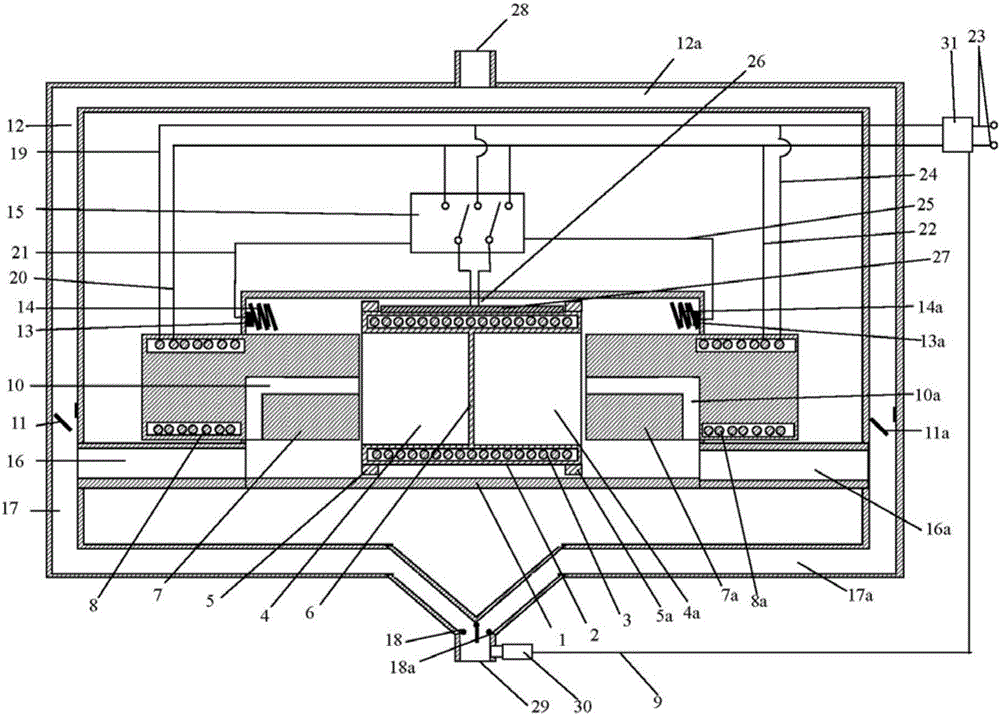

[0010] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] Depend on figure 1 Given, the present invention comprises pump body, pipeline part and control part, and pump body 1 is cylindrical hollow structure, and pump body 1 two ends are fixed with the first electromagnetic column 7 and the second electromagnetic column 7a that are arranged symmetrically opposite, the first electromagnetic column Both the post 7 and the second electromagnetic post 7a are half placed outside the pump body, and half are placed inside the pump body. The first electromagnetic post and the second electromagnetic post on the external part of the pump body are respectively wound with a first electromagnetic coil 8 and a second electromagnetic post. The coil 8a, between the first electromagnetic column and the second electromagnetic column, is provided with an electromagnetic plug tube 2 sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com