Pipe fitting for conveying high pressure acetylene

A technology of pipe fittings and acetylene, which is applied in the direction of pipe components, pipes/pipe joints/pipe fittings, pipes, etc., can solve the problems of large waste, difficult processing, and long processing time of small filling pipes, so as to reduce waste, realize safe transportation, The effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

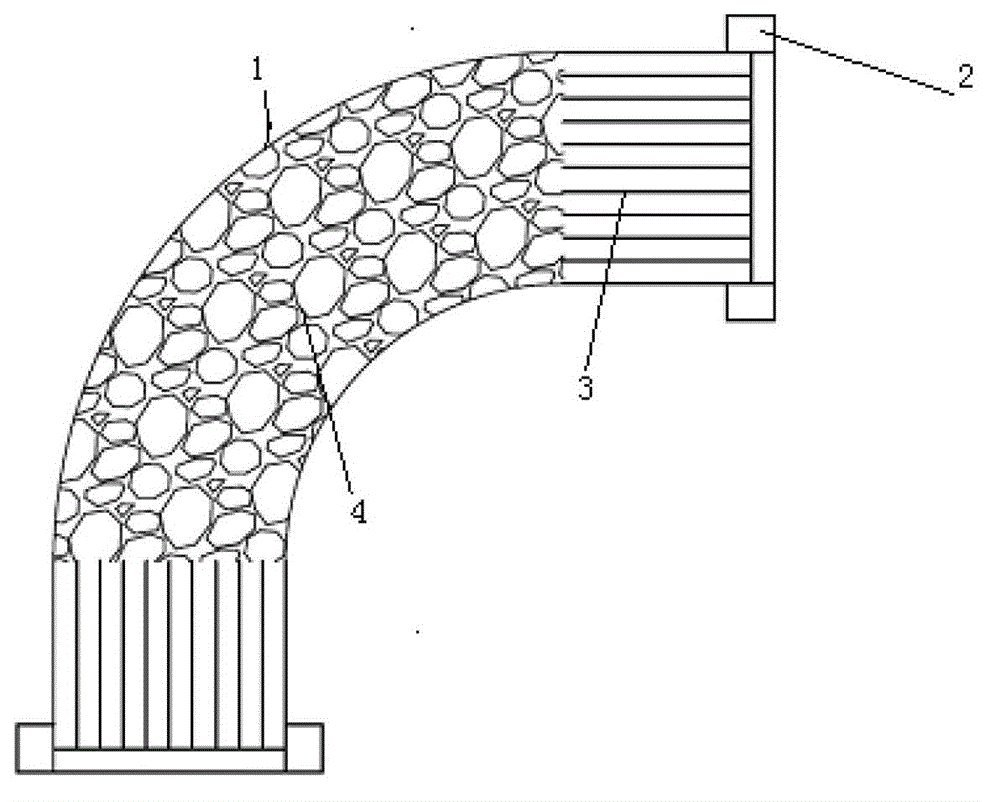

[0018] see figure 1 , which is the longitudinal section structure diagram of the elbow in the pipe fittings for high-pressure acetylene transportation. Among them, flange 2, tube bundle mother tube, tube bundle 3, packing 4, etc. are connected in sequence as shown in the figure, and the tube bundle near the flange end is flush with the flange surface. The filler adopts φ6×6mm plastic Raschig rings, the outer diameter of the tube bundle parent tube is 500mm, and the wall thickness of the tube bundle is 12mm; the tube bundle outer diameter is 10mm, the tube bundle wall thickness is 0.5mm, and the material of the tube bundle is stainless steel thin-walled tube; After 6 months of trial operation, the pipe fittings are running normally.

Embodiment 2

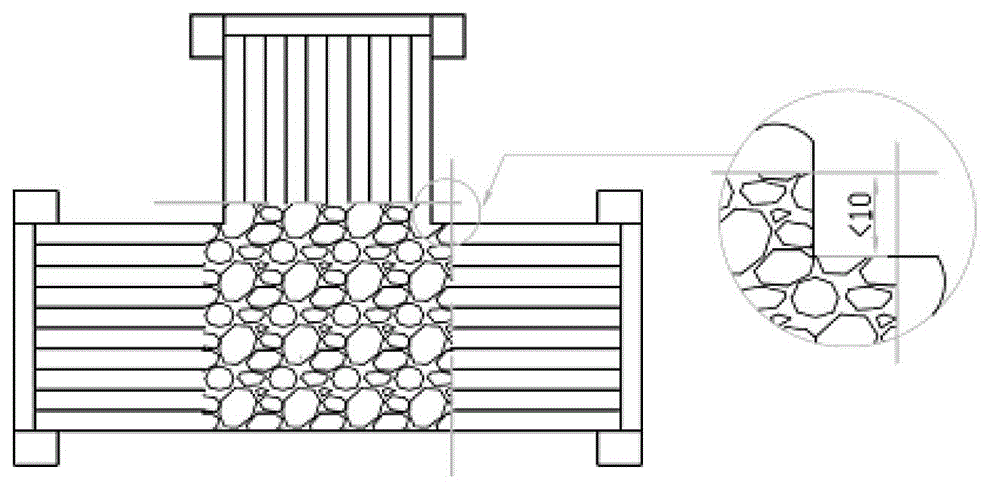

[0020] see figure 2 , which is the vertical cross-sectional structural diagram of the tee in the pipe fittings for high-pressure acetylene transportation. Among them, the distance between the tube bundle and the filler contact end in the branch main pipe and the outer wall of the main pipe main pipe shall not be greater than 10mm. The filler adopts φ6×6mm plastic Raschig rings, the outer diameter of the main tube of the tube bundle is 500mm, and the wall thickness of the main tube is 12mm; the outer diameter of the tube bundle is 10mm, the wall thickness of the tube bundle is 0.5mm, and the material of the tube bundle is stainless steel thin-walled tube; the tube bundle in the branch tube main tube is in contact with the filler The end is flush with the outer wall of the main pipe in charge. Under the acetylene pressure of 2.5MPa, after 6 months of trial operation, the pipe fitting operates normally.

Embodiment 3

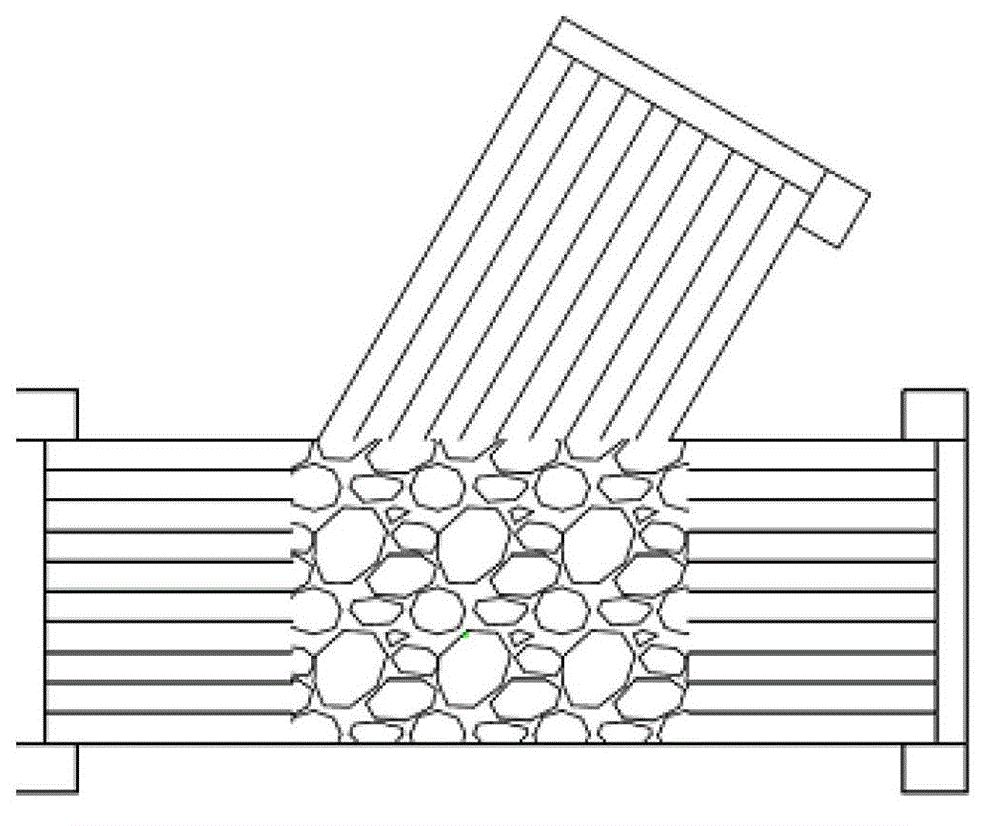

[0022] see image 3 , which is the vertical cross-sectional structure diagram of the oblique tee in the pipe fittings for high-pressure acetylene transportation. The angle between the inclined tube and the straight tube can be any angle between 0-90°, which is determined according to the process requirements. The angles between the inclined pipe and the straight pipe used in this example are 30° and 60°. The filler adopts φ6×6mm plastic Raschig rings, the outer diameter of the tube bundle parent tube is 500mm, and the wall thickness of the tube bundle is 12mm; the tube bundle outer diameter is 10mm, the tube bundle wall thickness is 0.5mm, and the material of the tube bundle is stainless steel thin-walled tube; After 6 months of trial operation, the pipe fittings are running normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com