Method of using gear measuring center to measure and evaluate gear surface roughness

A gear measurement and roughness technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of limited automation, manual adjustment of stylus rough positioning, complicated data processing, etc., to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions in the embodiments of the present invention will be described in more detail below in conjunction with the drawings in the embodiments of the present invention.

[0051] The technical terms involved in the description of the present invention are described as follows;

[0052] Trajectory profile: When measuring the surface, the track of the center point of the stylus in the cross-section of the surface to be measured, other profiles are derived from this profile.

[0053] Raw Profile: Passed λs The total contour after contour filtering.

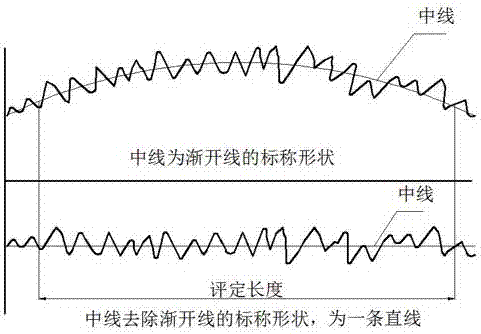

[0054] Roughness profile: for the original profile λc The contour filter is the contour formed after suppressing the long-wave components.

[0055] S 1 , Using the gear shape measuring instrument to implement the measurement method of surface roughness.

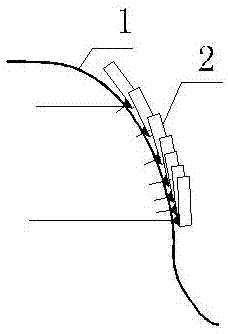

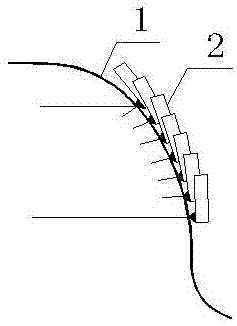

[0056] S 11 1. Install a stylus dedicated to measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com