A Method of Measuring the Lateral Force of Anchor Rod Using Fiber Bragg Grating

A technology of fiber gratings and fiber grating strings, which is applied in the field of force measurement using fiber grating sensors to measure the lateral force of anchor rods. It can solve the problems of inaccurate measurement, small number of settings, and low reliability, so as to increase the amount of data, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described below.

[0028] Implementation of the present invention provides a method for measuring the lateral force of the anchor rod using fiber gratings, which is realized by arranging several fiber grating strain sensors on the anchor rod according to certain rules. The situation proceeds as follows:

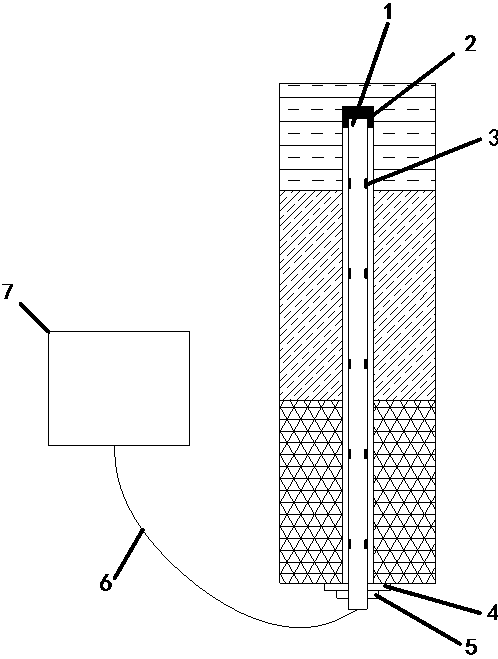

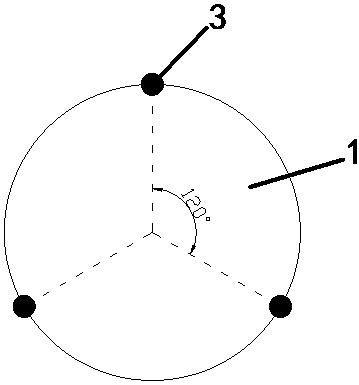

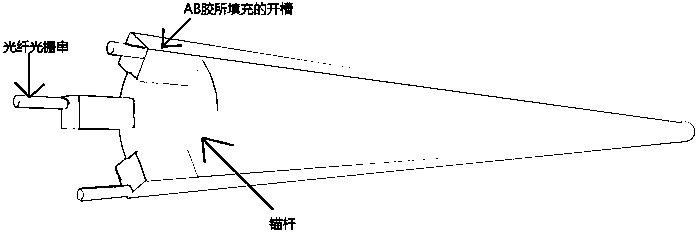

[0029] 1) Process three grooves on the longitudinal surface of a solid anchor rod 1 at 120° to each other, arrange three strings of fiber gratings in it, arrange five fiber gratings equidistantly on each string of fiber gratings, and fix them with AB glue , and then use the anchoring agent 2 and the backing plate 4 to fix the anchor rod 1 in the groove.

[0030] 2) Then the rock formation is in contact with the bolt 1, and when the rock formation changes, a force is applied to the bolt 1, which causes the bolt 1 to deform. Then the fiber grating 3 arranged at the corresponding position on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com