A method for evaluating the homogeneity of molten glass

A glass fluid and homogeneity technology, which is applied in image analysis, data processing applications, instruments, etc., can solve problems such as difficulty in judging areas with similar colors, analysis errors, and urgent need to improve the accuracy of medium homogenization evaluation, etc., to achieve easy operation , avoid large errors, eliminate the effect of human interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

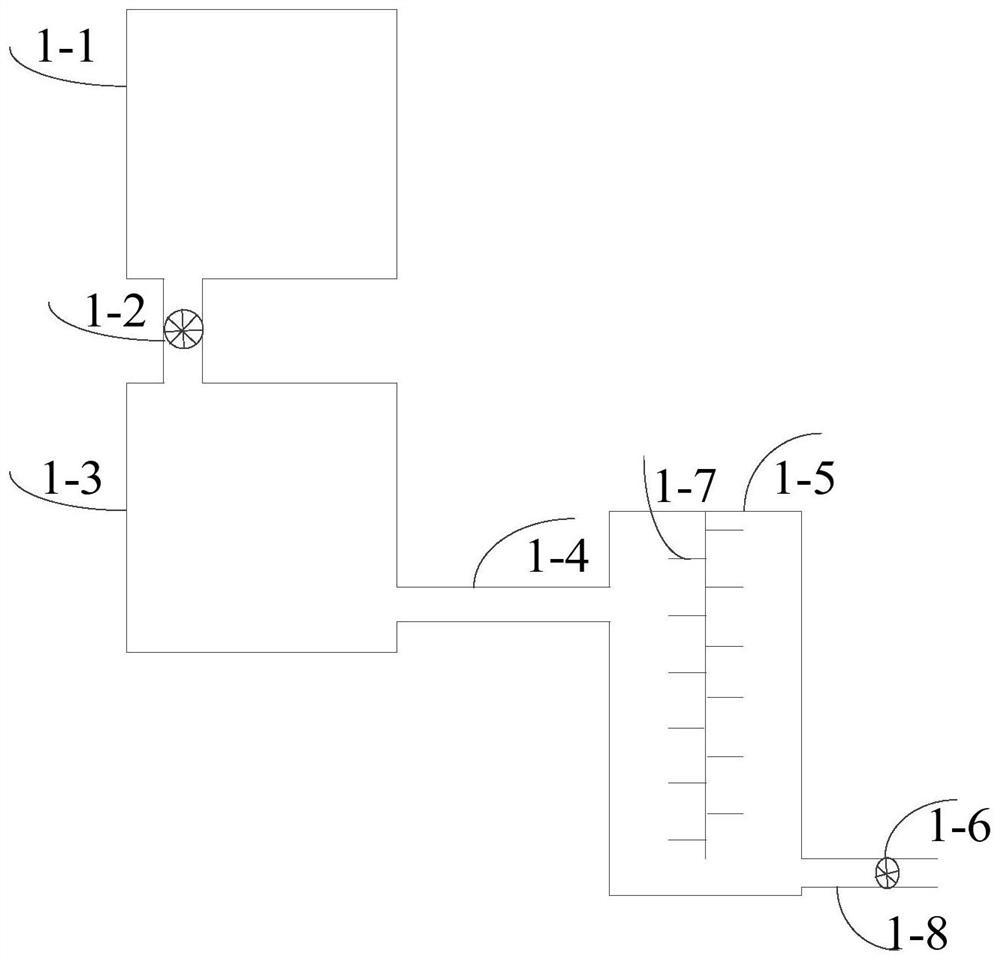

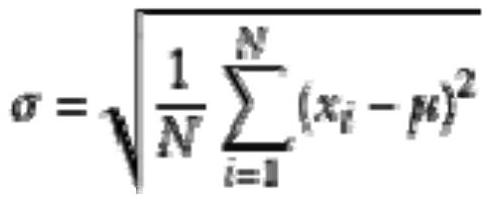

[0052] Select the mixing process of red silicone oil and colorless silicone oil to simulate the homogenization process of the glass melt, and use the process parameters 1 and 2 of the homogenized glass melt to simulate respectively. The flow rate of the glass melt in parameter 1 and parameter 2 is 330Kg / h. They are all located at a distance of 60mm from the bottom of the mixing tank. The difference between parameter 1 and parameter 2 lies in the stirring speed. The stirring speed of parameter 1 is 8rpm, and the stirring speed of parameter 2 is 10rpm; the mixing of red silicone oil and no Color silicone oil photos, extract the R, G, B value of each pixel, and calculate the weighted R, G, B value of each pixel: f (RGB) =R*P R +G*P G +B*P B , where P i =1 / 3, i=R, G, B, namely:

[0053] Q=1 / 3×R+1 / 3×G+1 / 3×B,

[0054] Each pixel gets a corresponding Q value, 1000 pixels are extracted and weighted for each simulation parameter, and the frequency of each Q value is counted, and t...

Embodiment 2

[0057] The mixing process of red silicone oil and colorless silicone oil is selected to simulate the homogenization process of glass liquid, and the process parameters 3 and 4 of the homogenized glass liquid are used for simulation respectively. Both are 9rpm, and the difference between parameter 3 and parameter 4 lies in the position of the stirring rod. The stirring rod of parameter 3 is located at a position 80mm away from the bottom of the mixing tank, and the stirring rod of parameter 4 is located at a position 50mm away from the bottom of the mixing tank; respectively, parameters 3 and The photo of mixed red silicone oil and colorless silicone oil under parameter 4 extracts the R, G, and B values of each pixel, and converts the R, G, and B values of each pixel into a YUV color model, namely:

[0058] Y=0.3*R+0.59*G+0.11*B

[0059] U=(B-Y)*0.493

[0060] V=(R-Y)*0.877

[0061] The Y, U, and V values obtained by each pixel are weighted to obtain the Q value corre...

Embodiment 3

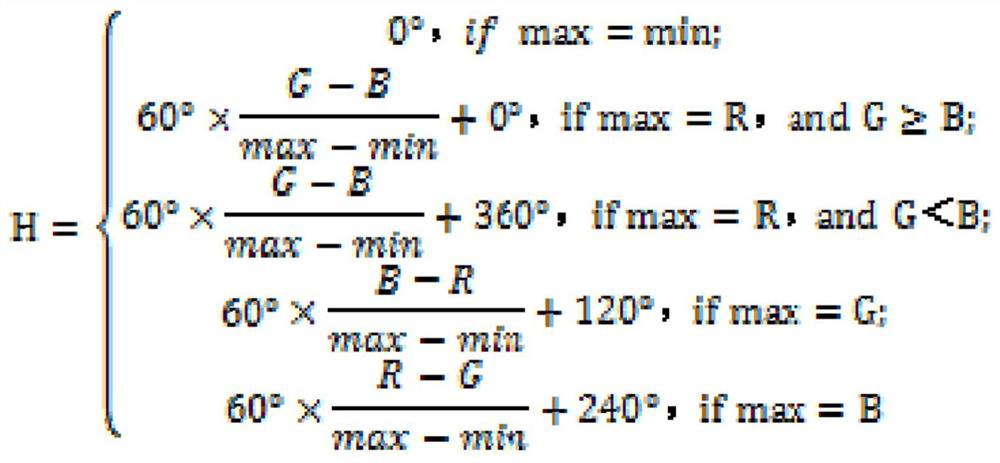

[0067] The mixing process of blue silicone oil and colorless silicone oil is selected to simulate the homogenization process of glass melt, and the process parameters 5 and 6 of the homogenized glass melt are respectively used for simulation. The stirring speed of parameter 5 and parameter 6 is 10rpm, and the stirring rods are located at At a position 60mm from the bottom of the mixing tank, the difference between parameter 5 and parameter 6 lies in the flow rate of the glass liquid, the flow rate of parameter 5 is 300kg / h, and the flow rate of parameter 6 is 350Kg / h; the blue silicone oil mixed with parameter 5 and parameter 6 was photographed respectively And the photo of colorless silicone oil, extract the R, G, B value of each pixel, convert the R, G, B value of each pixel into the HSV color model, namely:

[0068]

[0069]

[0070] V=max

[0071] Among them, max=max(R, G, B); min=min(R, G, B);

[0072] Perform weighted calculations on HSV to obtain the Q value of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com