Reflective film capable of improving photovoltaic conversion efficiency and preparation method thereof

A technology of photovoltaic conversion and reflective film, which is applied in the field of reflective film, can solve the problems of inconvenient use, difficulty in welding ribbon processing, and low efficiency, and achieve the effect of increasing the reflection area and improving the utilization rate of solar energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

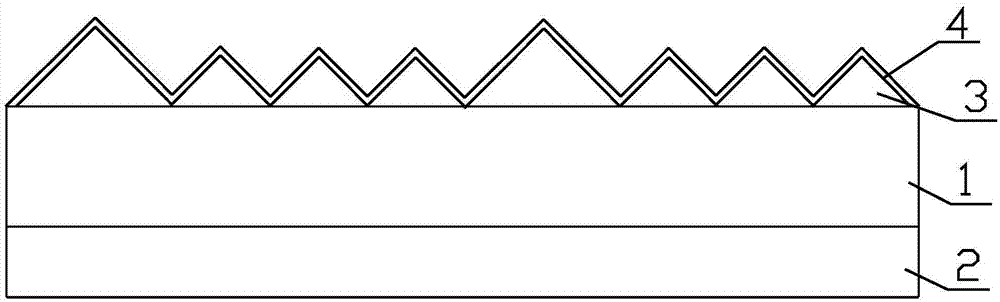

[0029] 1. Such as Figure 1-2 As shown, the reflective film for improving photovoltaic conversion efficiency of this embodiment includes a substrate layer 1 and an adhesive layer 2 provided on the lower layer of the substrate layer 2, a microstructure layer 3 provided on the upper layer of the substrate layer 1, and The light-reflecting layer 4 above the microstructure layer 3.

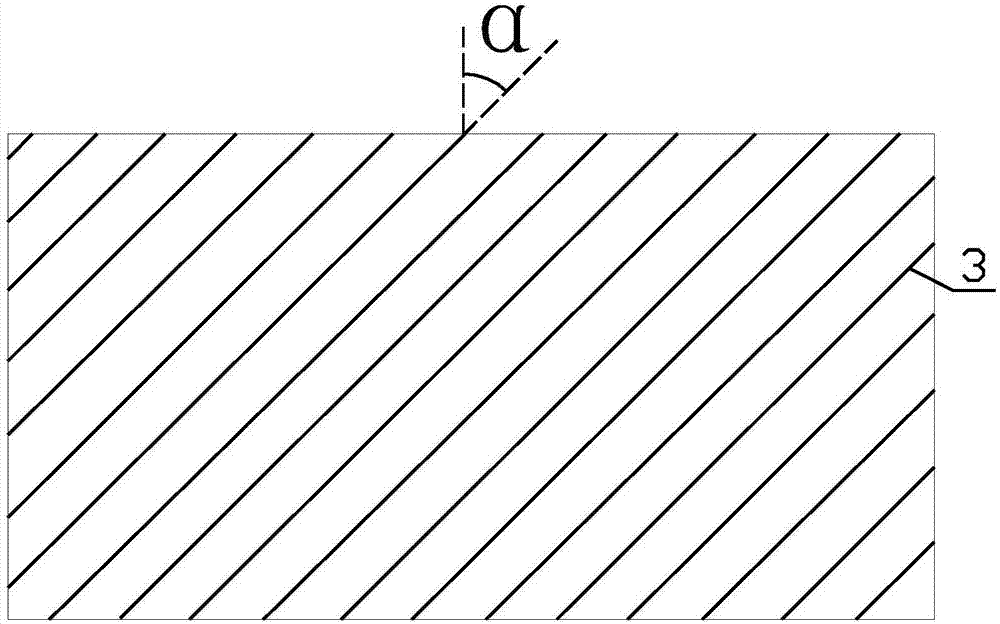

[0030] The microstructure layer 3 is composed of a plurality of parallel triangular prisms arranged in sequence. The angle between the extending direction of the triangular prism and the extending direction of the base layer 1 is α, and α is 45°. The cross section of the triangular prism is an isosceles triangle, and the vertex angle of the isosceles triangle is 120°. The apex angle of the isosceles triangle may be a sharp angle or a circular arc angle, and the radius of the circular arc angle is R, 0.5<R<5μm. The vertex angle of an isosceles triangle can also be cut by a straight line or a wavy line, ...

Embodiment 2

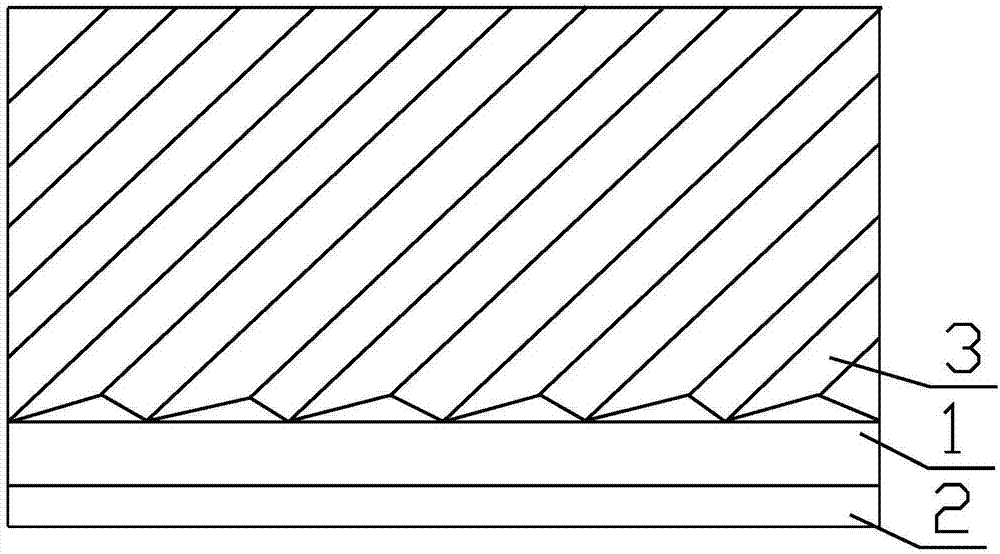

[0040] Such as Figure 3-4 As shown, the reflective film for improving photovoltaic conversion efficiency of this embodiment includes a substrate layer 1 and an adhesive layer 2 provided on the lower layer of the substrate layer 2, a microstructure layer 3 provided on the upper layer of the substrate layer 1, and The light-reflecting layer 4 above the microstructure layer 3.

[0041] The microstructure layer 3 is composed of a plurality of parallel triangular prisms arranged in sequence. The extending direction of the triangular prism is consistent with the extending direction of the base layer 1. The cross section of the triangular prism is an isosceles triangle, the vertex angle of the isosceles triangle is 60-145°, the height is 10-500 μm, and the distance between two adjacent triangular prisms is 15-300 μm. The angle between the extending direction of the triangular prism and the extending direction of the base layer 1 is α, and 0<α<90°. In this embodiment, α is 45°. The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com