Glass tube carrying manipulator

A technology for glass tubes and manipulators, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of redness on the surface, worker injury, and low efficiency of workers handling glass tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

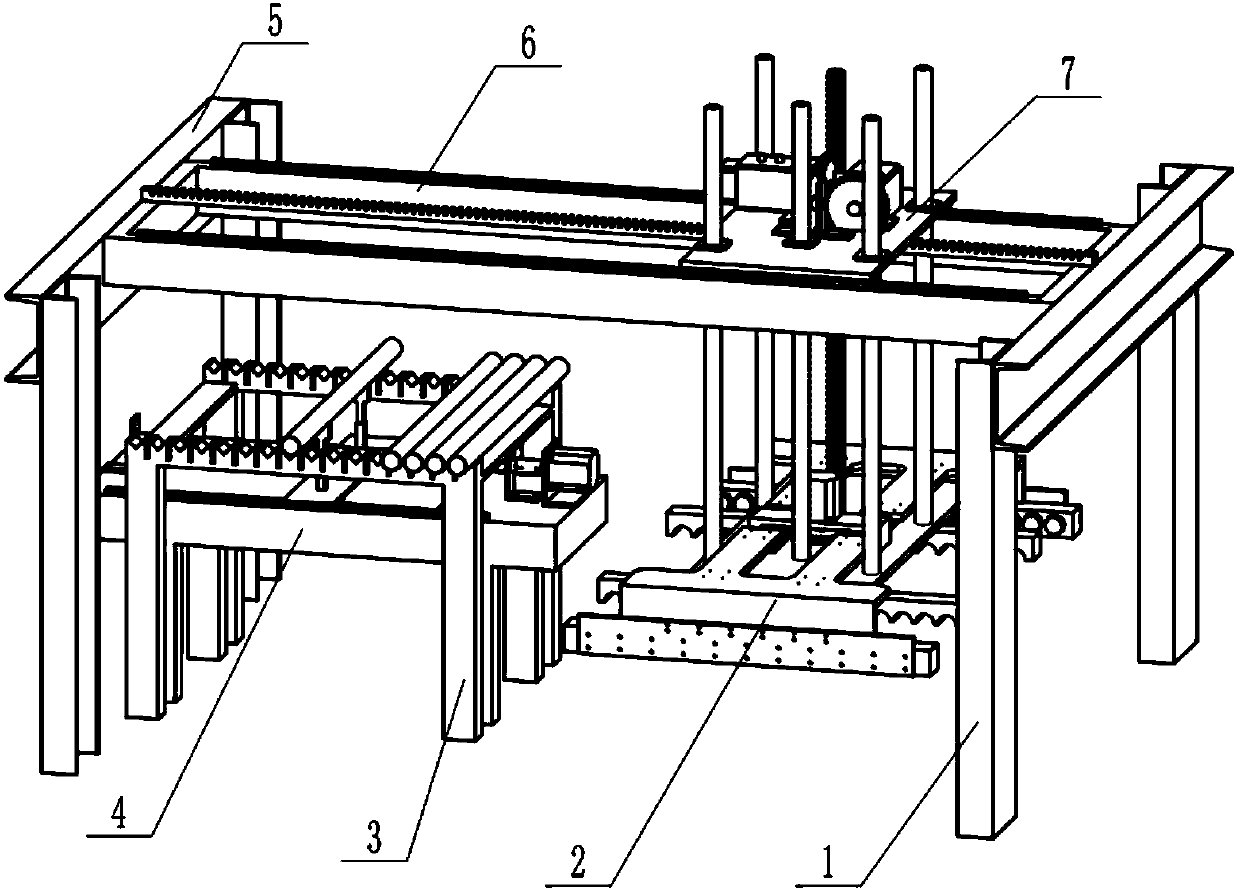

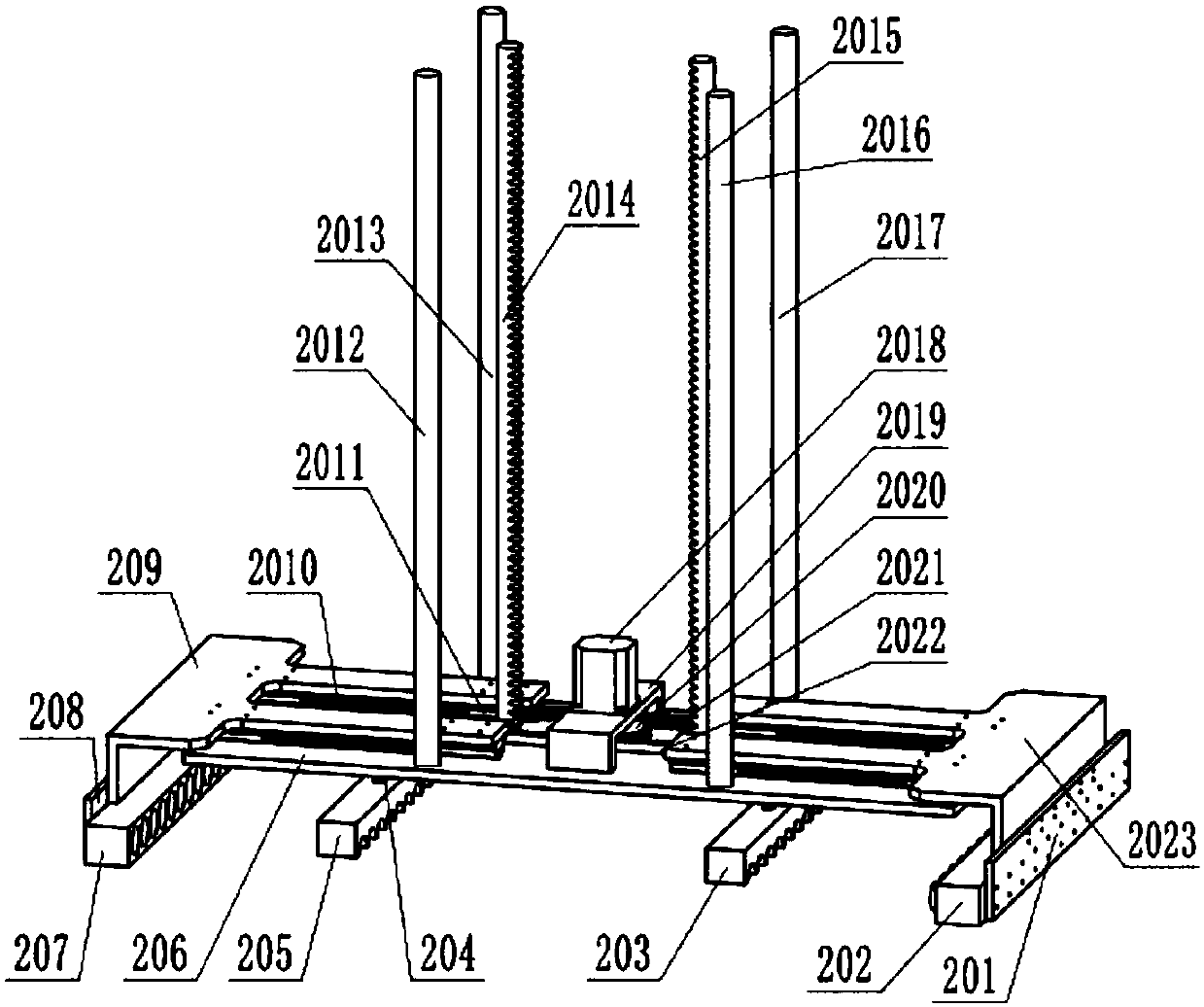

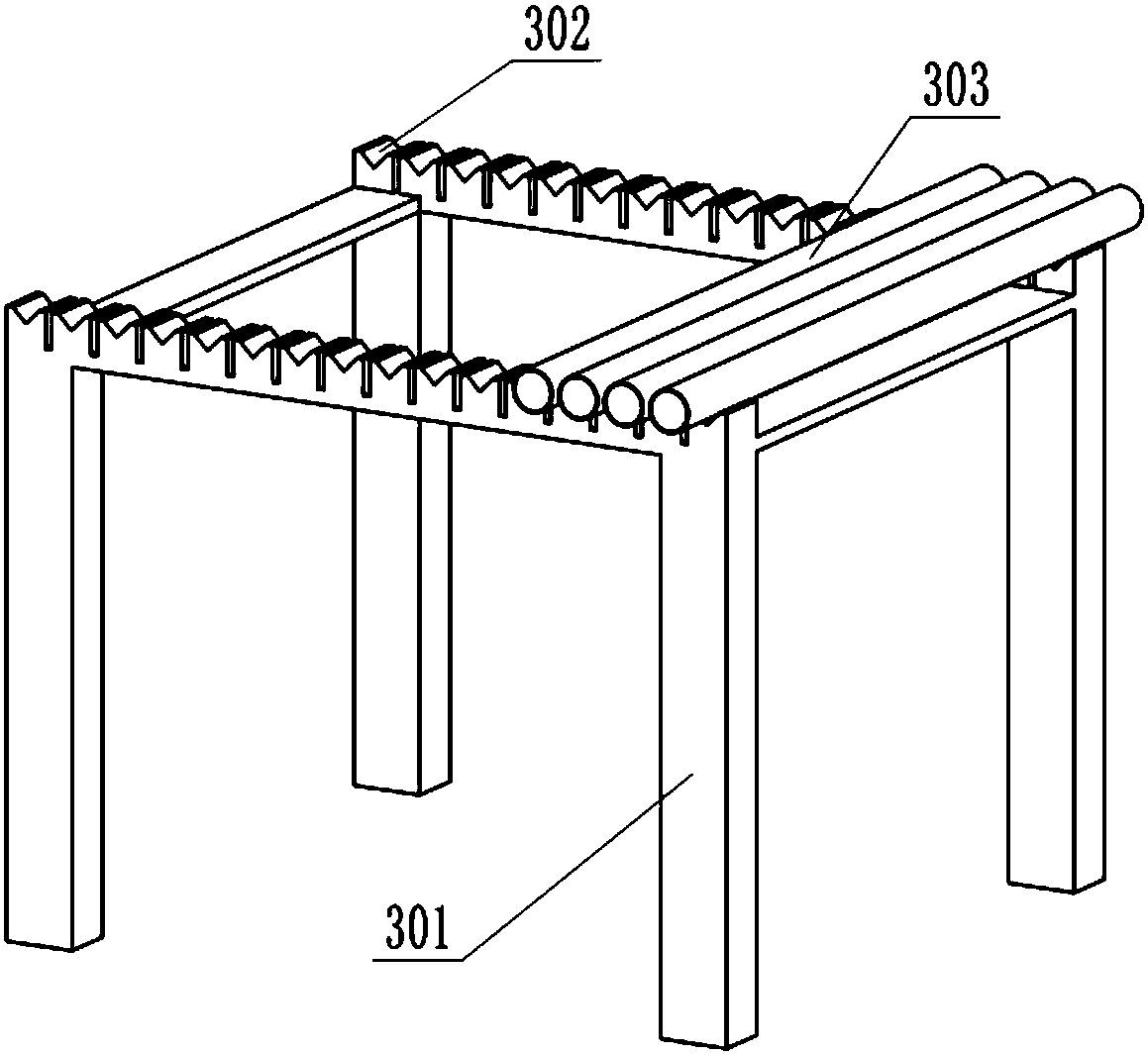

[0018] A glass tube handling manipulator, which is assembled by a first bracket 1, a glass tube clamping mechanism 2, a glass tube fixing device 3, a glass tube delivery mechanism 4, a second bracket 5, a lifting motor unit rail assembly 6 and a lifting motor unit body 7 composition. The lifting motor unit track assembly 6 is connected between the first bracket 1 and the second bracket 5, the lifting motor unit assembly 7 is on the lifting motor unit track assembly 6, and the straight line with the lifting motor unit track assembly 6 The guide rail sliders are connected, the glass tube clamping mechanism 2 is connected with the hoisting motor unit assembly 7 through hole shaft cooperation and rack and pinion cooperation, and the glass tube fixing device 3 is placed directly under the hoisting motor unit track assembly 6 and close to the second The support 5 and the glass tube delivery mechanism 4 are placed directly below the glass tube fixing device 3 .

[0019]The glass tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com