Sealing structure of bus hinge cabin door

A sealing structure and hinge technology, which is applied in the field of passenger car side cabin doors, can solve problems such as unsatisfactory sealing, door falling off, and easy aging of rubber, and achieve the effects of reducing size requirements, increasing sealing stability, and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

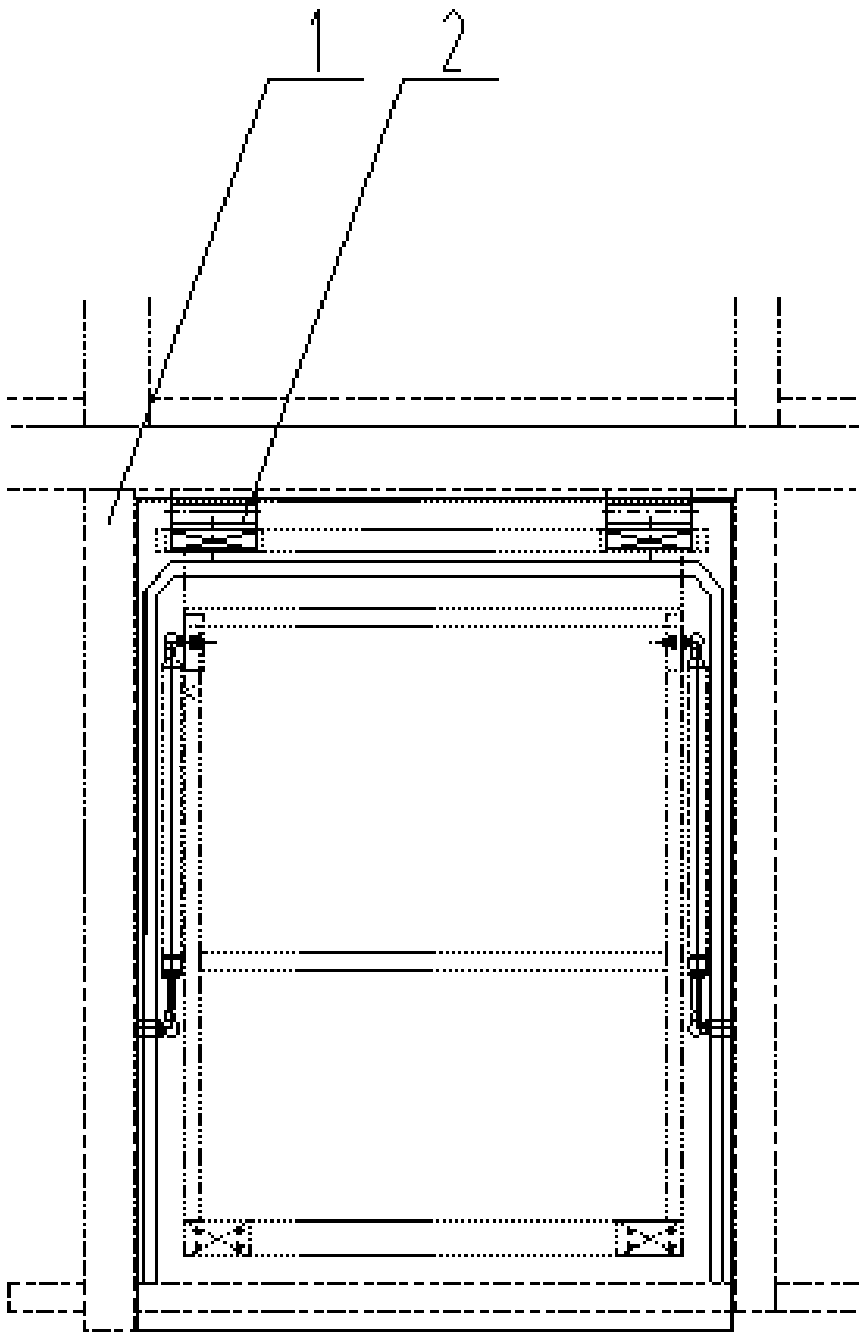

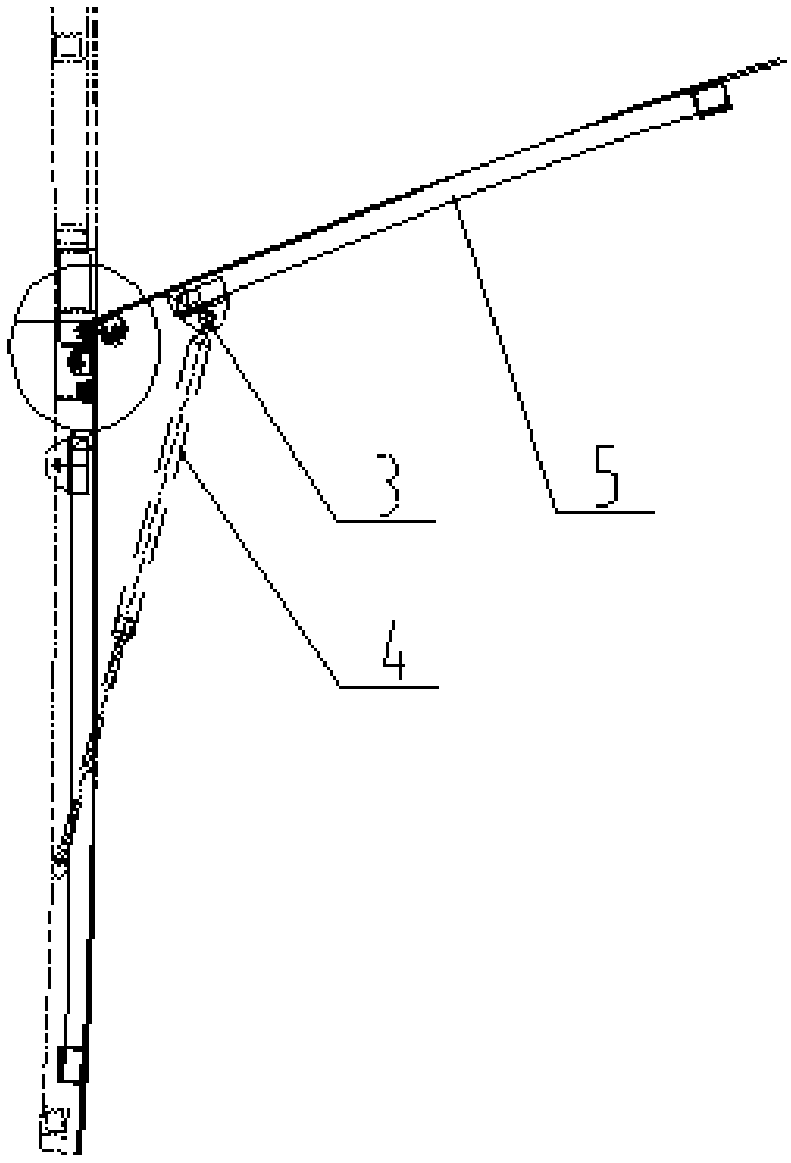

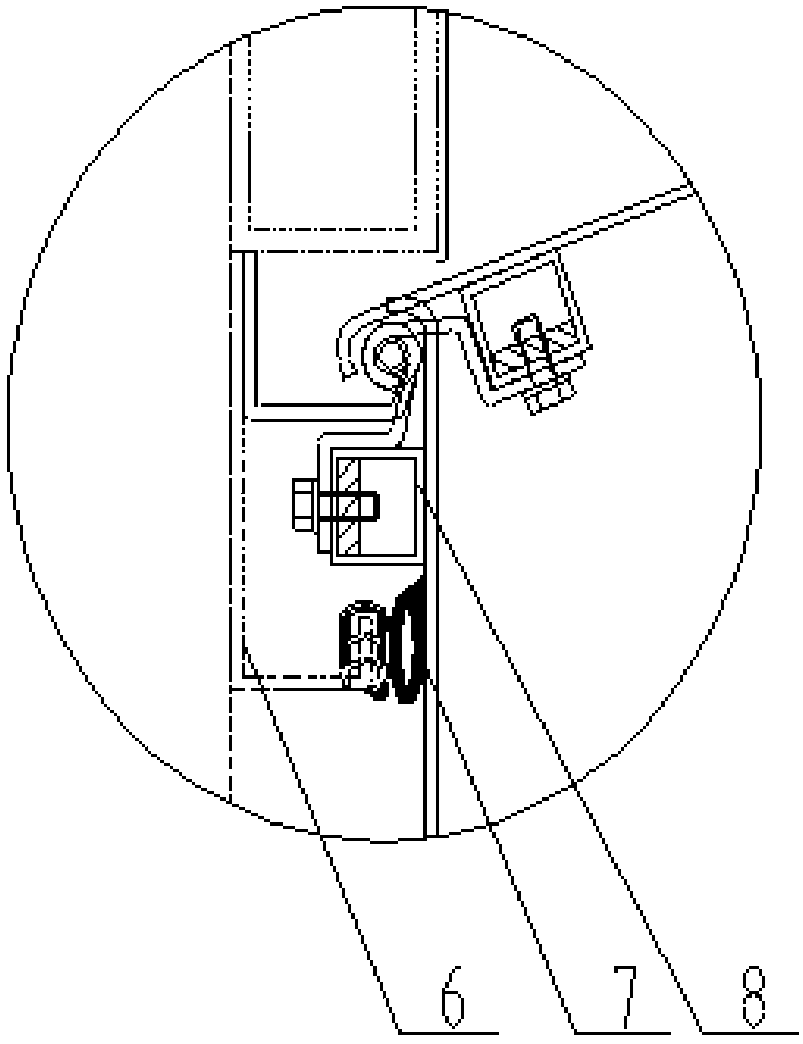

[0029] A passenger car hinged door sealing structure 5, its structure is as follows figure 1 with figure 2 Shown, comprise body frame 1, side door 5, door hinge 2, gas strut 4, body frame 1 is provided with door opening, described door hinge 2 is installed in door opening, one end of side door 5 is connected with The hatch hinge 2 is connected and turned over with the hatch hinge 2. One end of the gas strut 4 is hinged to the body frame 1, and the other end is hinged to the gas strut support 3 on the side hatch 5. The hatch hinge 2 is an iron cabin. The door hinge 2, the door opening is also provided with an L-shaped sealing stop 6 in the lower position of the hatch door hinge 2, the surrounding of the sealing stop 6 is welded and sealed with the inner edge of the door opening, and the welding seam between the sealing stop 6 and the inner edge of the door opening Can also play sealant, the seam between the front end of seal spigot 6 and vehicle body frame 1 snaps into rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com