Powder automatic weighing equipment and weighing method thereof

A technology of automatic weighing and equipment, which is applied in the direction of weighing, weighing equipment and measuring devices for materials with special properties/forms, and can solve the problems of low production efficiency, high requirements for operator proficiency, and low automation, etc. problems, to achieve the effect of improving production efficiency, saving human resources, and accurate automatic weighing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

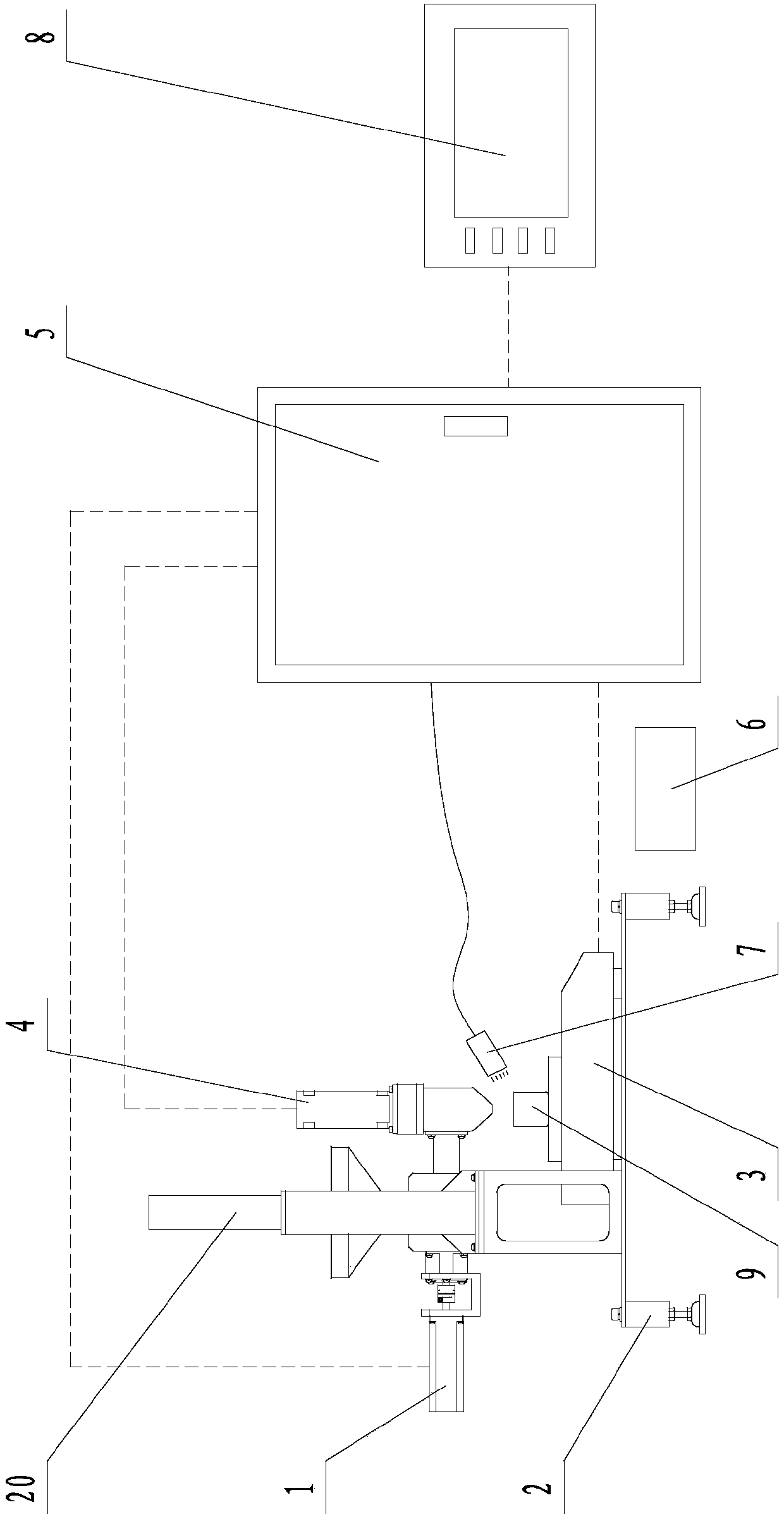

[0021] like figure 1 As shown, the present invention includes a powder feeding mechanism 1, a mounting bracket 2, a weighing sensor 3, a micro powder feeding mechanism 4, a weighing controller 5, a dust concentration detection instrument 6, a static eliminator 7, a touch screen 8 and a material cup 9, Wherein the powder feeding mechanism 1 and the weighing sensor 3 are installed on the mounting bracket 2 respectively, the material cup 9 is placed on the weighing sensor 3 , and the micro powder feeding mechanism 4 is connected with the powder feeding mechanism 1 and is located above the material cup 9 . The weighing sensor 3 can be a weighing sensor, or an electronic balance with a communication function can be used to feed back the current weight data to the control system online at all times.

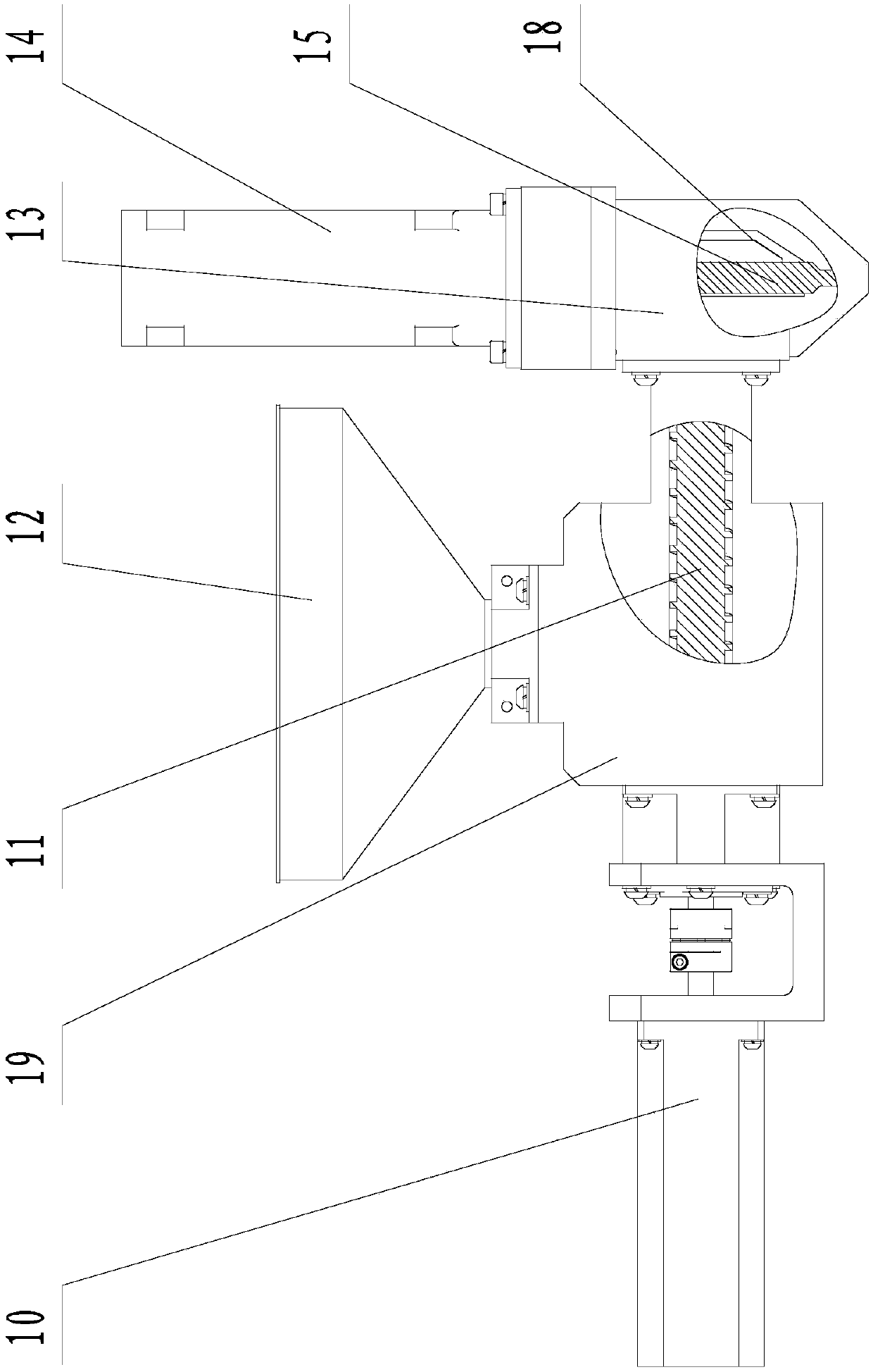

[0022] like figure 2 As shown, the powder feeding mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com