Laser beam bunching secondary reflection structure

A technology of secondary reflection and laser beam, which is applied in optics, optical components, instruments, etc., can solve the problems that the application of light sources cannot be widely promoted, the size of the light source system is large, and the cross-sectional area of the light source is large. The effect of entrance pupil diameter, reduced spot diameter, and overall structure setting is reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

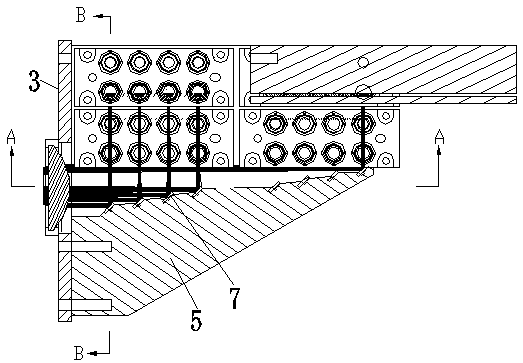

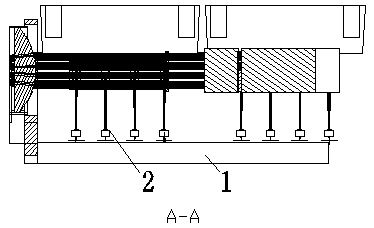

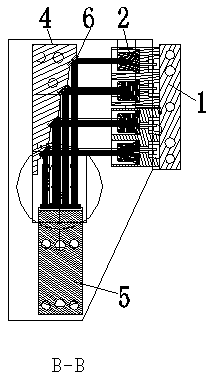

[0015] Such as figure 1 , figure 2 and image 3 As shown, a laser focusing secondary reflection structure according to the present invention includes a laser light source base 1, a laser light source 2 is arranged on the laser light source base 1, and a laser light source 2 is vertically arranged on one side of the laser light source base 1. There is a connecting plate 3, a first mirror seat 4 is provided on one side of the connecting plate 3, a second mirror seat 5 is provided at the other end, and a first mirror 6 is arranged on the first mirror seat 4 , a second reflector 7 is arranged on the second reflector seat 5, the first reflector 6 is arranged correspondingly to the exit of the laser light source 2, and the second reflector 7 is arranged correspondingly to the first reflector 6, The working surface angle between them is 60 °; The first ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com