Electrode assembly, lithium-oxygen thin film battery and preparation method

A technology of electrode assembly and positive electrode film, which is applied in the field of electrochemistry, can solve the problems of increasing the difficulty of electrode materials and electrolytes, affecting battery performance, and high time costs, so as to achieve high utilization of battery materials, reduce time costs, and reduce research costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

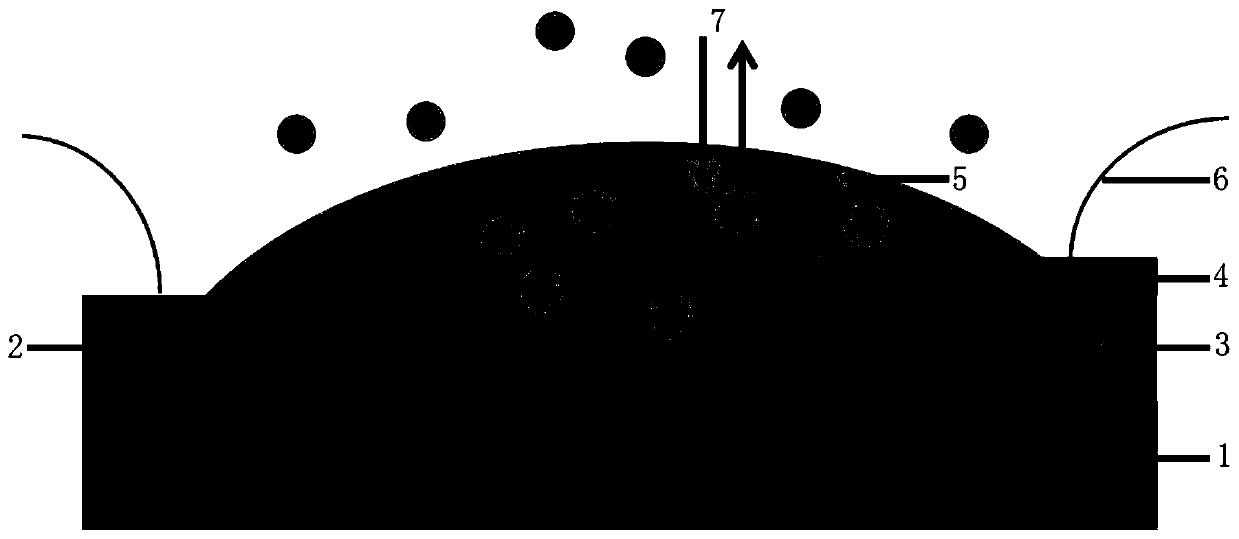

[0044] figure 1 A schematic structural view of the lithium-oxygen thin-film battery provided in this embodiment is shown. The lithium-oxygen thin-film battery is placed in a dry oxygen environment 7, which includes an electrode assembly, an electrolyte 5 and a wire 6. The electrolyte 5 in this embodiment is Ionic liquid, the electrode assembly includes an insulating substrate 1, a positive electrode film layer 2, a negative electrode film layer 3 and a protective layer 4, the positive electrode film layer 2 and the negative electrode film layer 3 are located on the same surface of the insulating substrate 1, and there is a certain distance between the two. spacing, the protective layer 4 is positioned on the upper surface of the negative film layer 3, the insulating substrate 1 of the present embodiment is a silicon wafer, and the area of the upper surface is about 1cm 2 , the positive electrode film layer 2 is a gold film, the area of the upper surface is about 0.5cm 2 ,...

Embodiment 2

[0054] The structure of the electrode assembly of this embodiment and the structure of the lithium-oxygen thin film battery are the same as in Example 1, and the preparation method of the electrode assembly is as follows:

[0055] 1) Use weak adhesive double-sided tape to cover about 1cm 2 A silicon substrate of the same size is adhered to a stainless steel substrate and covered with an aluminum foil strip about 0.5×1cm 2 a rectangular area of the silicon substrate so that the other half is about 0.5 x 1cm 2 The substrate area of the substrate is exposed, fix the two ends of the aluminum foil strip on the double-sided tape, iron the aluminum foil strip with a toothpick or other soft objects, and then transfer it into the vacuum preparation system;

[0056] 2) Using the thermal evaporation coating method, heat the tungsten boat with gold particles in a vacuum with a current of about 150A to liquefy and boil the gold particles. After the rate is stable, open the baffle, and...

Embodiment 3

[0062] The structure of the electrode assembly of this embodiment and the structure of the lithium-oxygen thin film battery are the same as in Example 1, and the preparation method of the electrode assembly is as follows:

[0063] 1) Use weak adhesive double-sided tape to cover about 1cm 2 A silicon substrate of the same size is adhered to a stainless steel substrate and covered with an aluminum foil strip about 0.5×1cm 2 a rectangular area of the silicon substrate so that the other half is about 0.5 x 1cm 2 The substrate area of the substrate is exposed, fix the two ends of the aluminum foil strip on the double-sided tape, iron the aluminum foil strip with a toothpick or other soft objects, and then transfer it into the vacuum preparation system;

[0064] 2) Using the electron beam evaporation coating method, set the voltage of the electron gun to 10kV in a vacuum, heat the gold particles and make them gasify, open the baffle after the rate is stable, and the gasified go...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com