Adjustable length connecting rod

A length-adjustable and adjustable technology, applied in the directions of connecting rods, machines/engines, mechanical equipment, etc., can solve the problem of not being able to obtain connecting rods, etc., and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

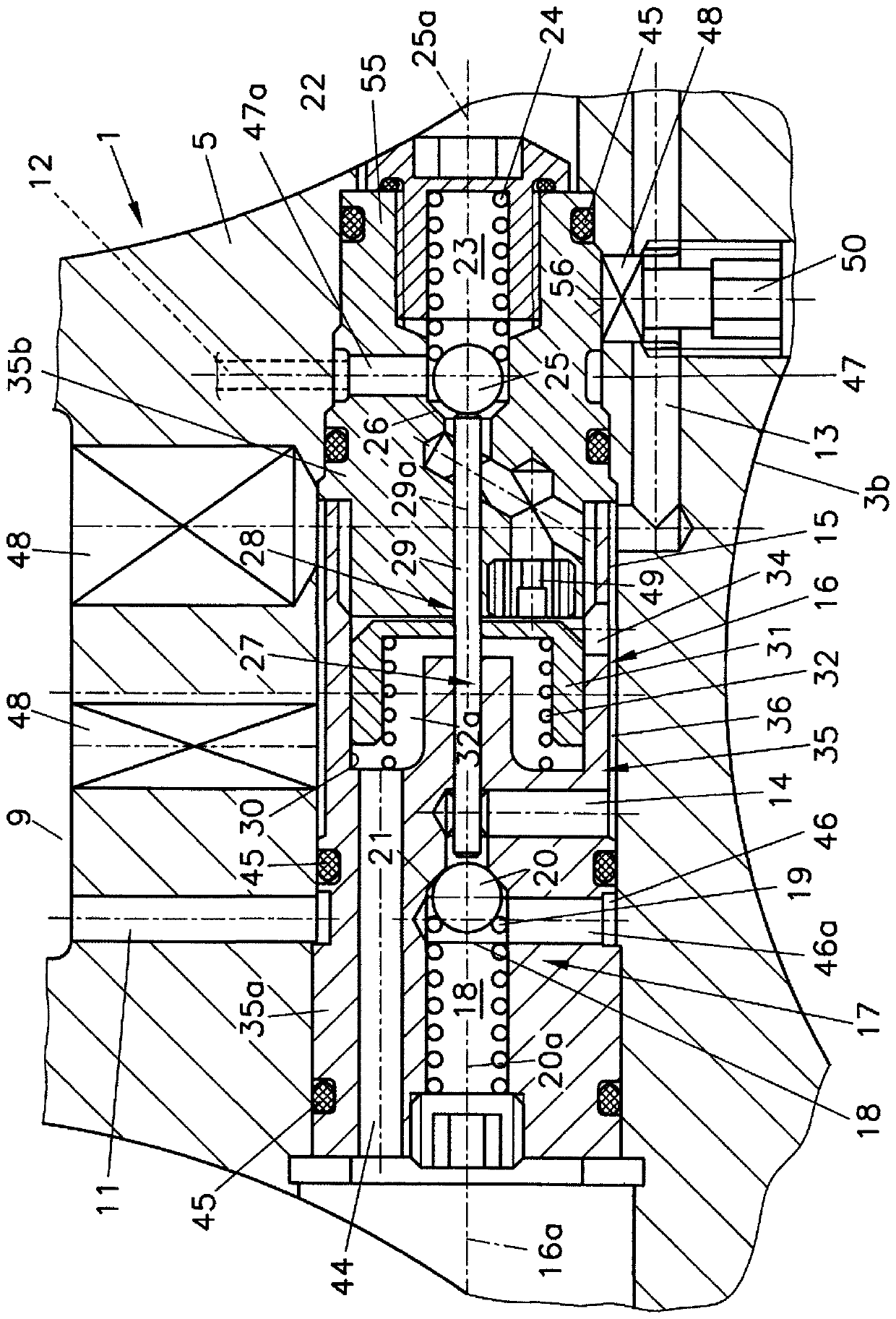

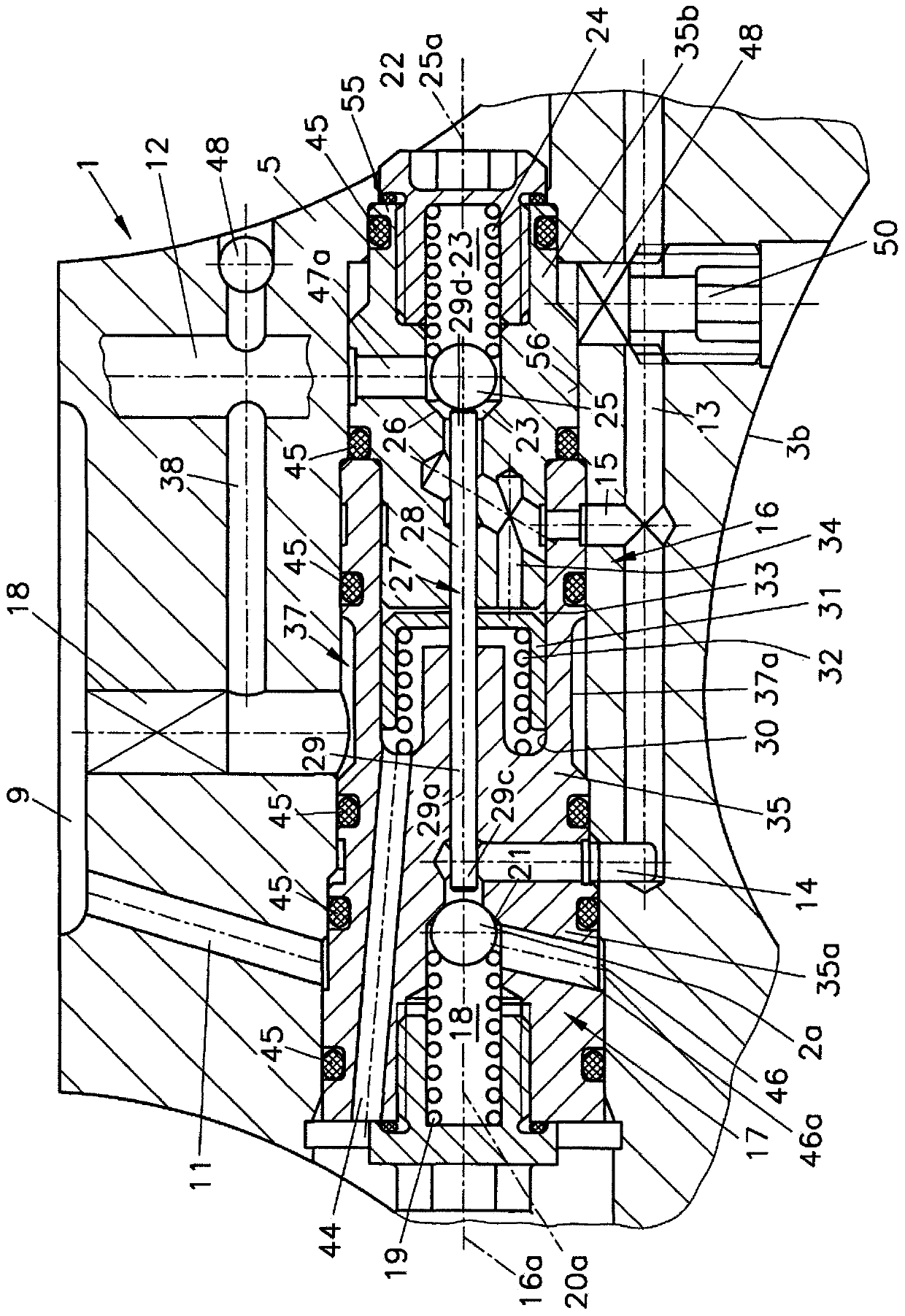

[0126] Functionally identical elements are provided with the same reference symbols in the embodiment variants shown in the figures.

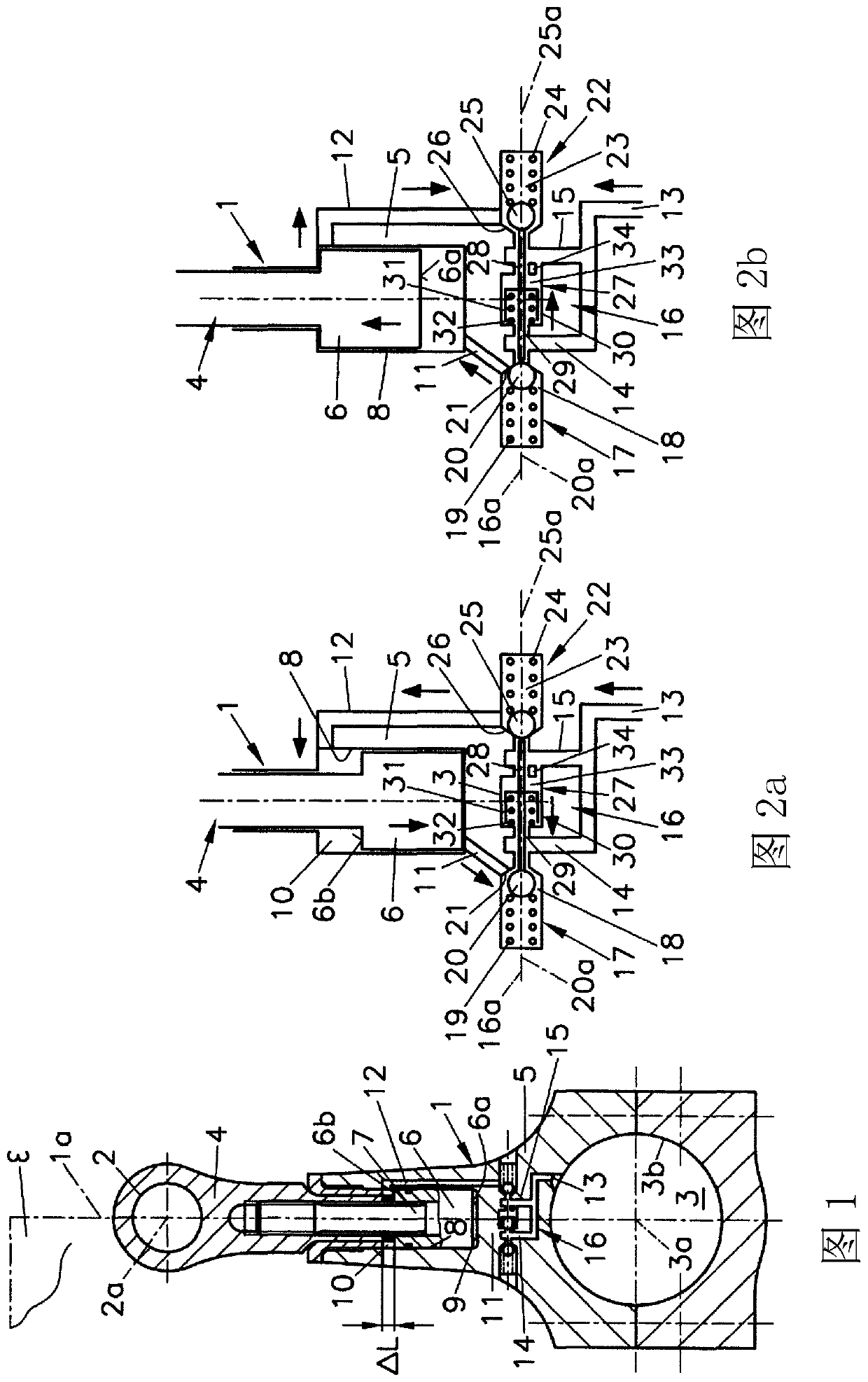

[0127] figure 1 Shown is a two-part connecting rod 1 for a piston engine, such as an internal combustion engine, with a small connecting rod 2 for a piston pin bearing (not further shown) and a large connecting rod 2 for a crankpin bearing (not further shown) for an internal combustion engine. The connecting rod 3. The axis of rotational symmetry of the small or large connecting rod 2 , 3 is indicated with 2 a or 3 a. The longitudinal axis of the connecting rod 1 is denoted by 1a, the longitudinal center plane of the connecting rod 1 normal to the axes of rotational symmetry 2a and 3a of the small and large connecting rods 2, 3 and containing the longitudinal axis 1a of the connecting rod 1 ( Swing plane) is denoted by ε.

[0128] The connecting rod 1 has an upper first rod part 4 with a small connecting rod 2 and a lower second rod part 5 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com