Semiconductor devices and methods of forming same

A semiconductor and device technology, applied in the field of forming through-substrate through-hole conductors, can solve problems such as multiple die areas, and achieve the effect of simplifying the process flow, fewer masks and process steps, and unlimited compactness and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

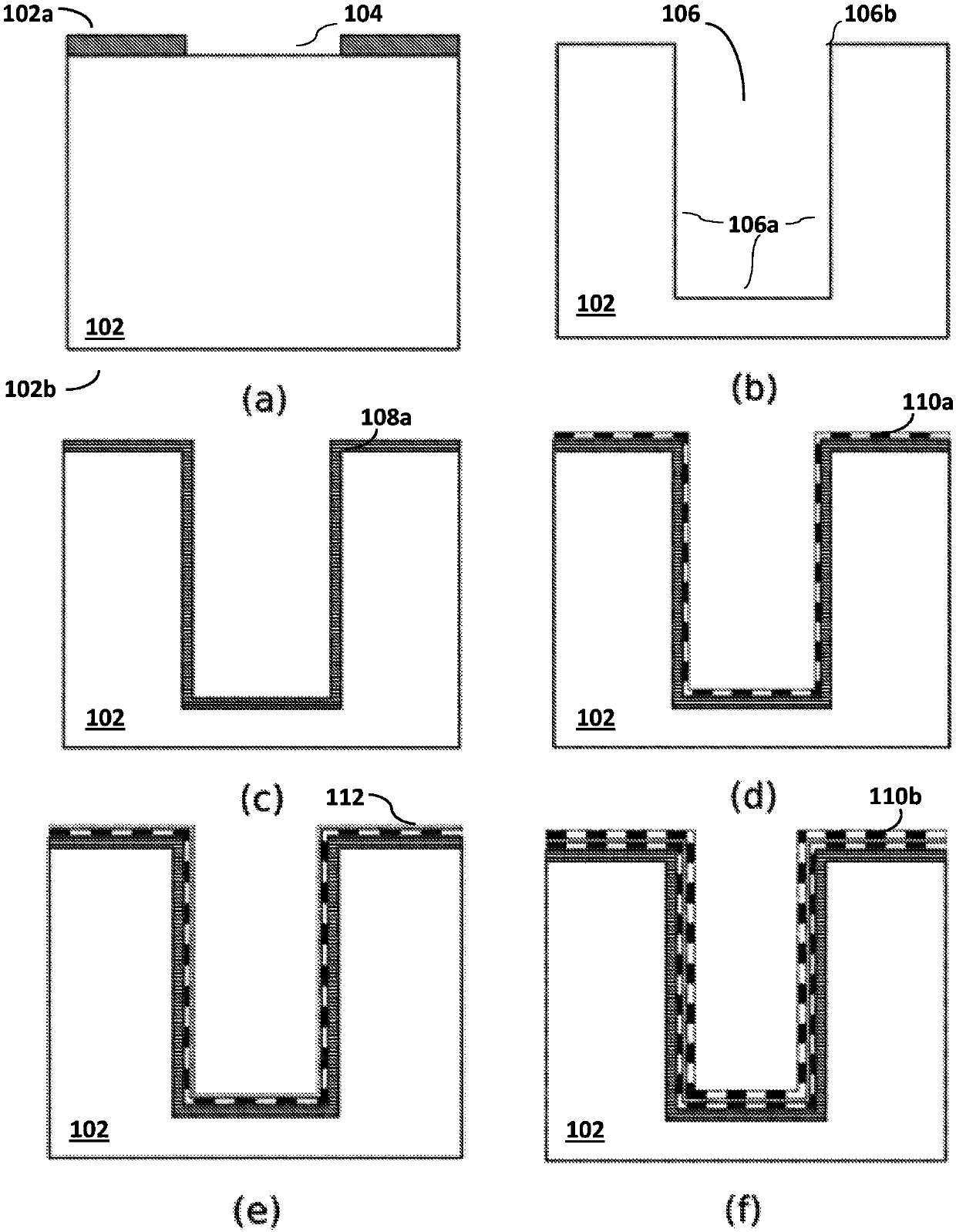

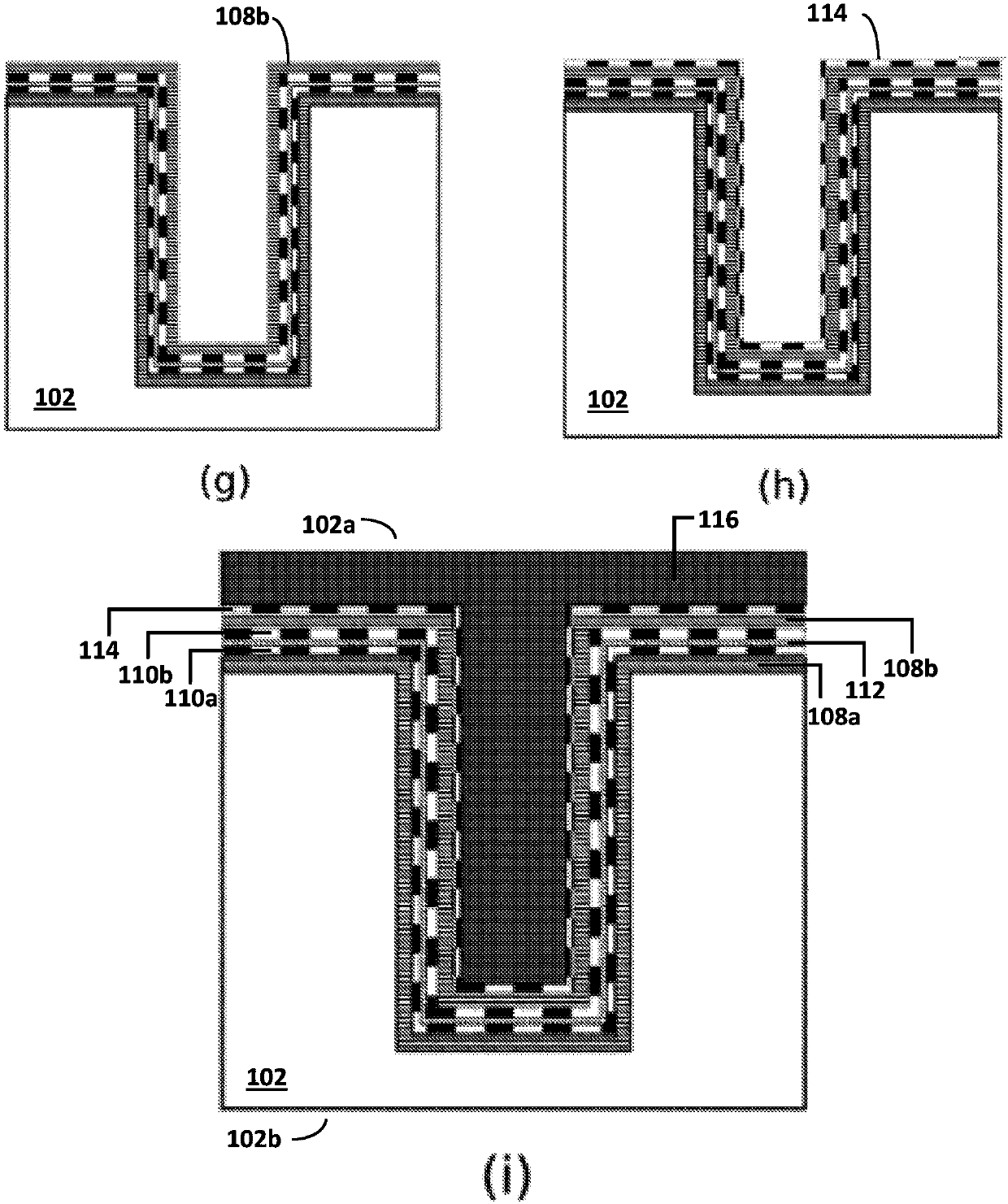

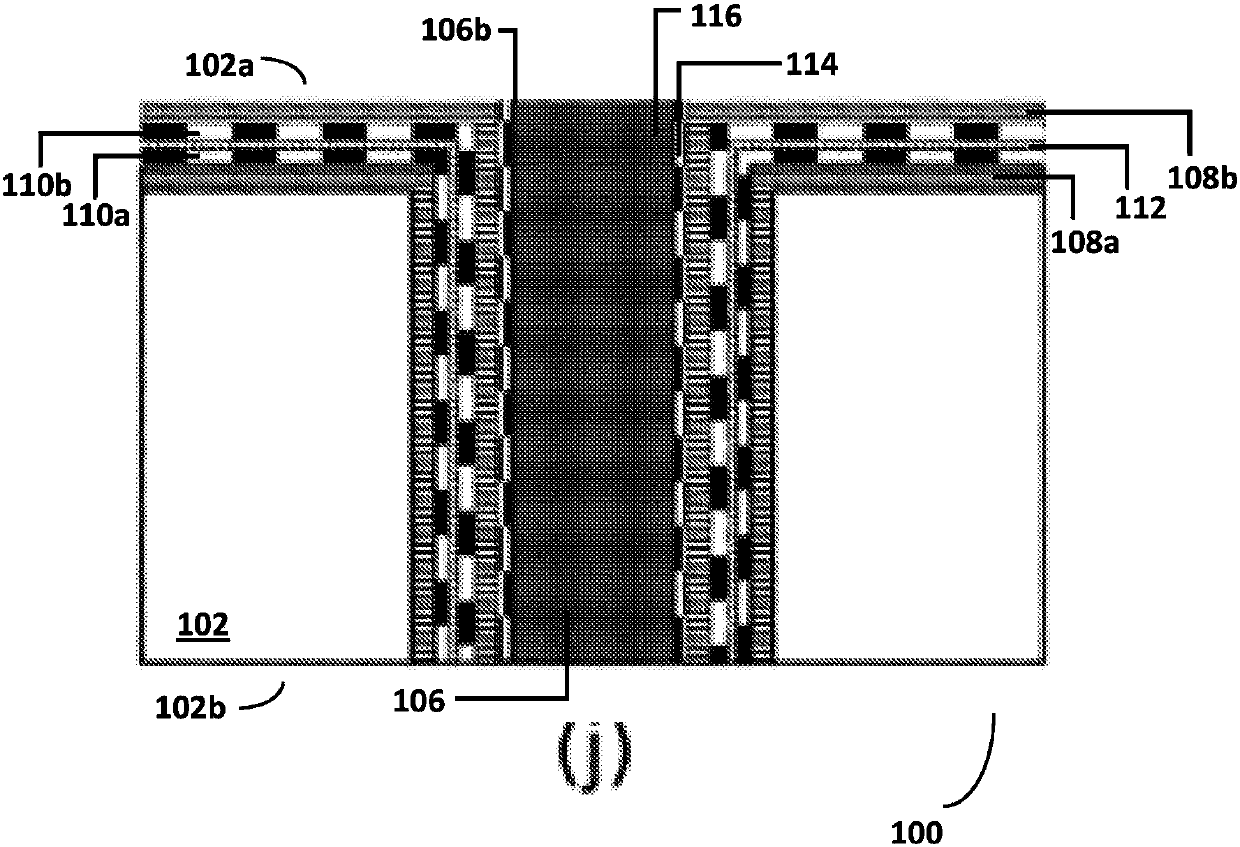

[0029] Now turning to the above mentioned figure 1 , which provides a series of figures illustrating an exemplary process flow for forming the first semiconductor device 100 . figure 1 (a) shows the substrate 102 having a first side 102a and a second side 102b. In at least one implementation, substrate 102 is at least partially formed of silicon. The window 104 is patterned from photoresist on the substrate 102, eg, by photolithography. In at least one implementation, window 104 has a square or generally square shape. In another implementation, the window 104 has a circular or generally circular shape. exist figure 1 In (b), a trench 106 is formed on the substrate 102 . In one example, trench 106 has a cross-sectional shape corresponding to the shape of the window. The groove 106 has an inner surface 106a. In this example, inner surface 106a may be the sidewall (or each sidewall) and / or the upper surface of the bottom of trench 106 . Trench 106 may be formed by a numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com