Osmunda cinnamomea blanching and conveying mechanism with self-lifting lifting tool

A technology of conveying mechanism and micro-vegetables, which is applied in the directions of conveyors, transportation and packaging, food processing, etc., can solve the problems of low work efficiency, affect the taste, fast wilting speed, etc., and achieve reliable structure, low cost of use, and efficient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below with reference to the accompanying drawings.

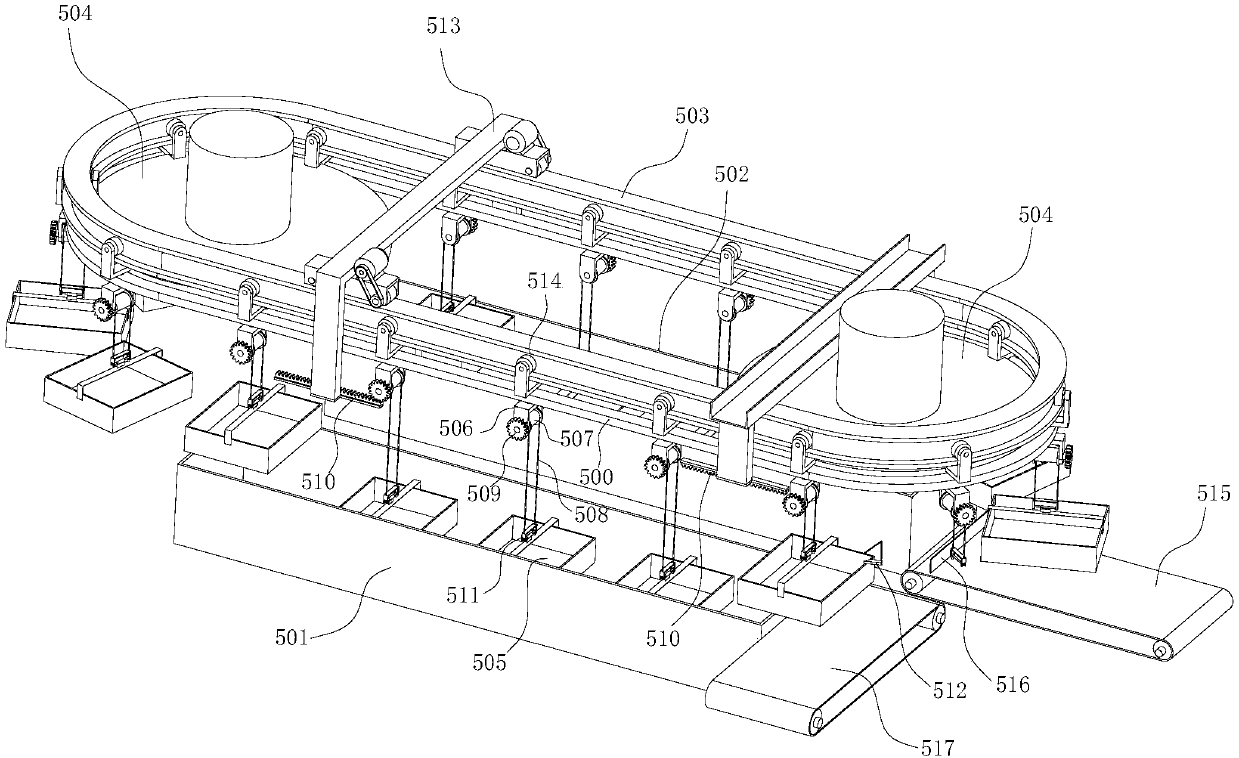

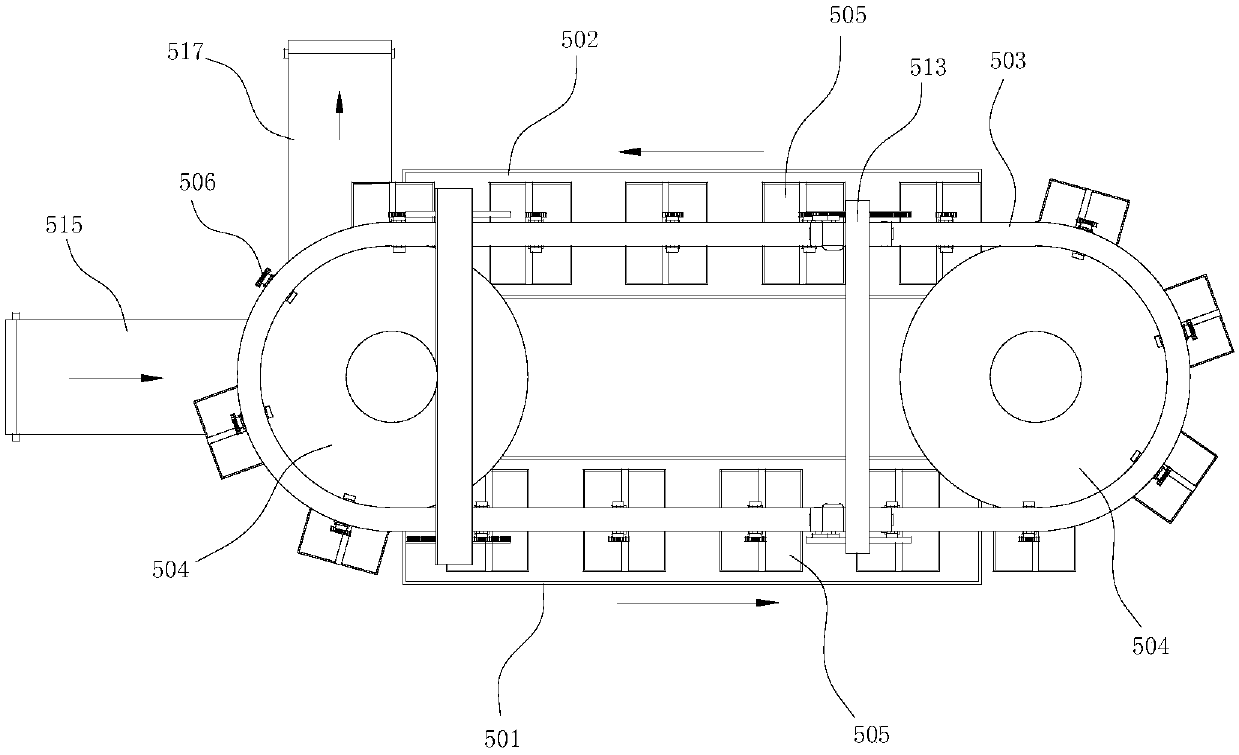

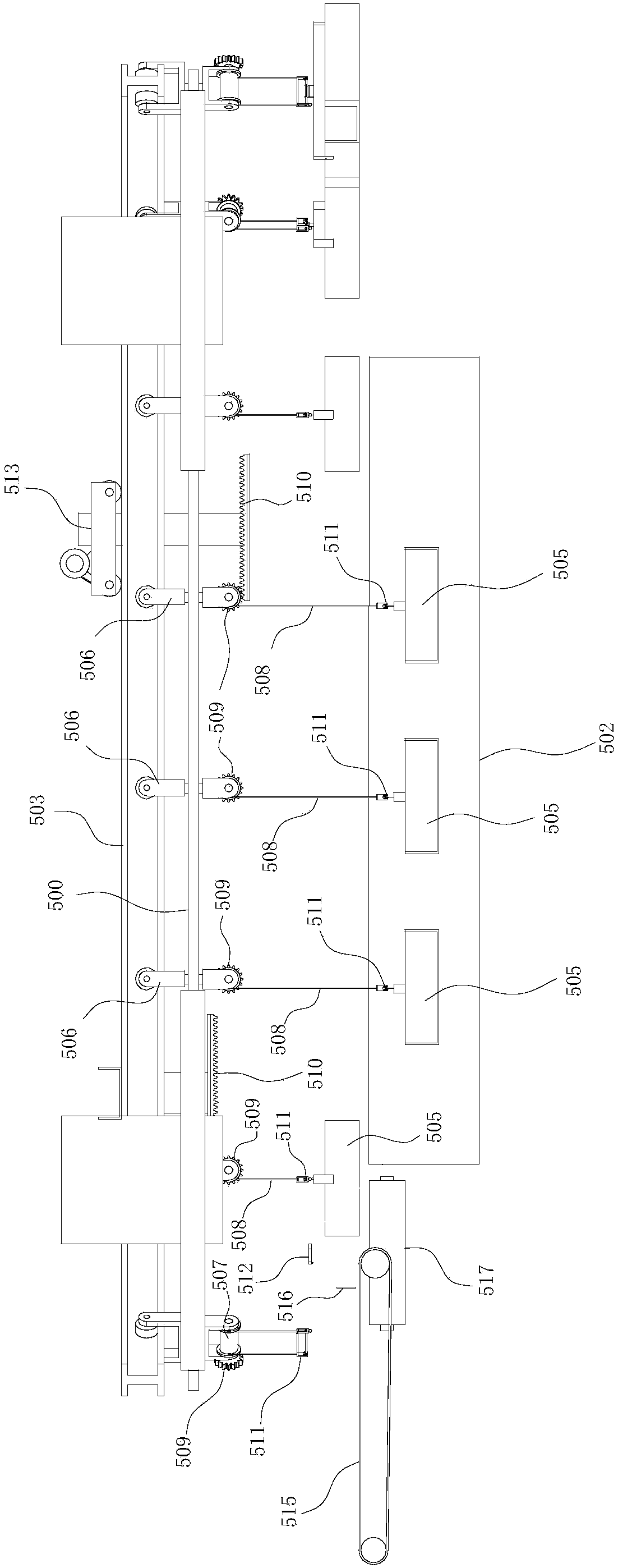

[0045] As shown in 1-9, a micro-vegetable hot-green color protection device includes a hanging conveyor chain 500 and a plurality of screen slots 505 suspended below the hanging conveyor chain 500 at intervals. The hanging conveyor chain A hot water tank 501 and a color protection tank 502 are sequentially arranged below the transportation path of 500. An independent lifting mechanism is provided between each of the sieve grooves 505 and the hanging conveyor chain 500. When the sieve groove 505 moves to the hot water tank When 501 and the color protection pool 502 are above, the lifting mechanism can lower the sieve groove 505 into the hot pool 501 and the color protection pool 502. The hot pool in the present invention is used for blanching green vegetables, and the color protection pool is used for holding special The prepared color protection liquid, the micro-vegetabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com