Equipment for dewaxing and degreasing rice oil at temperature of 0 DEG C

A rice oil, dewaxing technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of wasting cooling liquid cooling water, reducing the productivity of refined oil, etc.

Inactive Publication Date: 2018-05-15

王伟

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to solve the problem of wasting a large amount of coolant cooling water in the process of heat exchange and cooling in the prior art, and the use of crystal aids and filter aids in the process of dewaxing and degreasing, causing crystal aids and Filter aid entrains oil, which reduces the production rate of refined oil to a certain extent, and a 0-degree rice oil dewaxing and degreasing equipment is proposed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

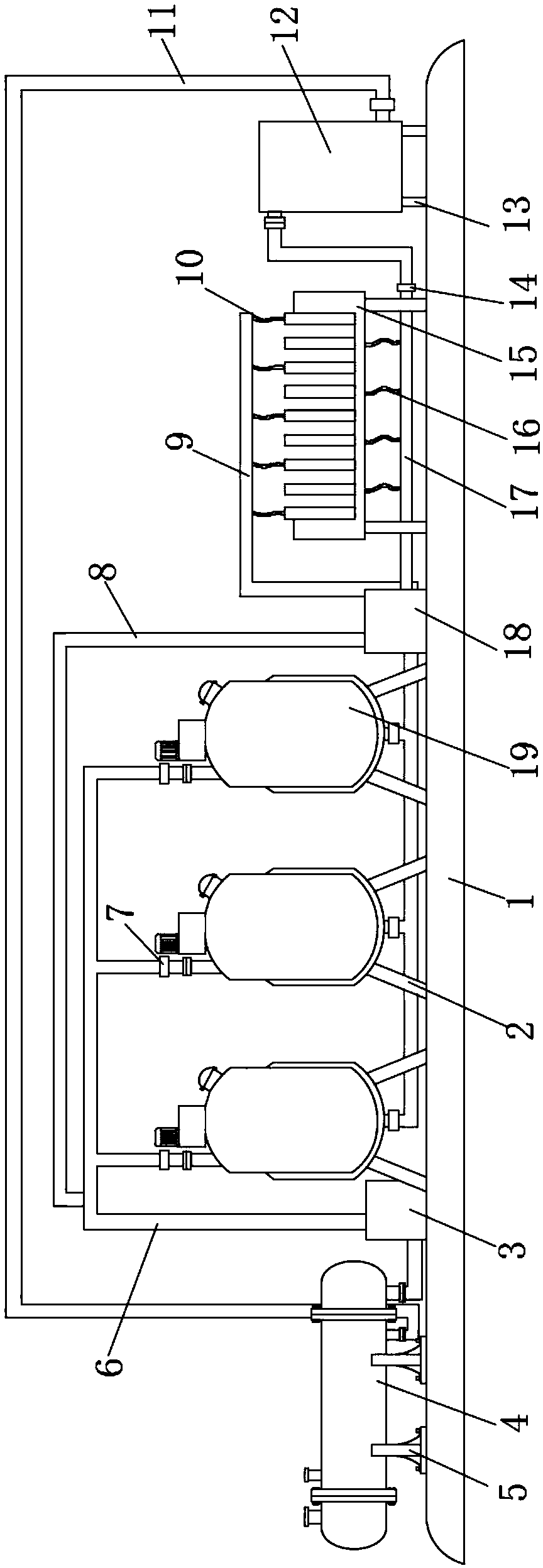

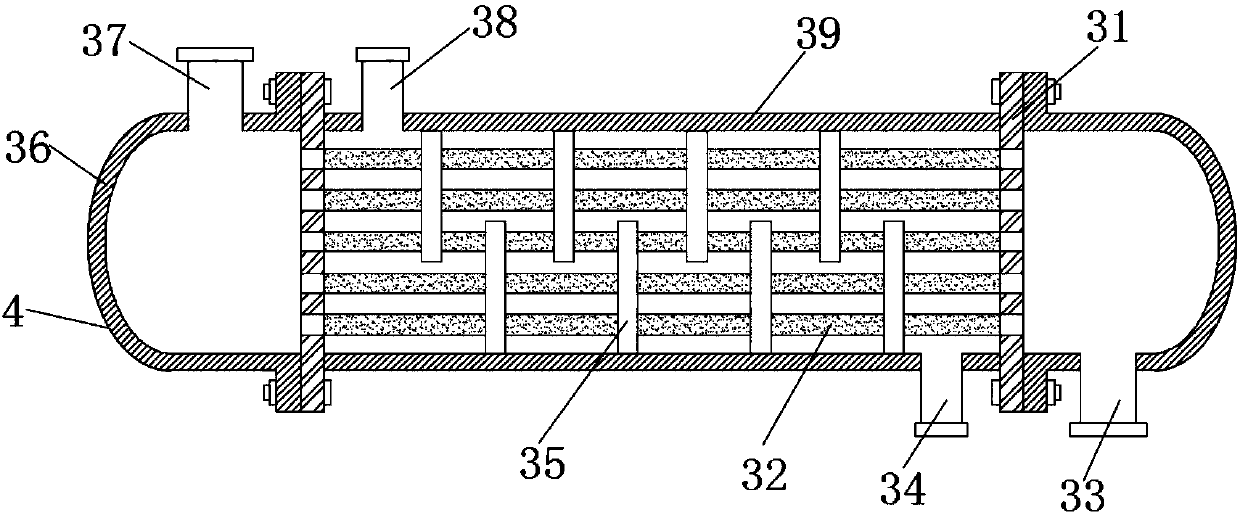

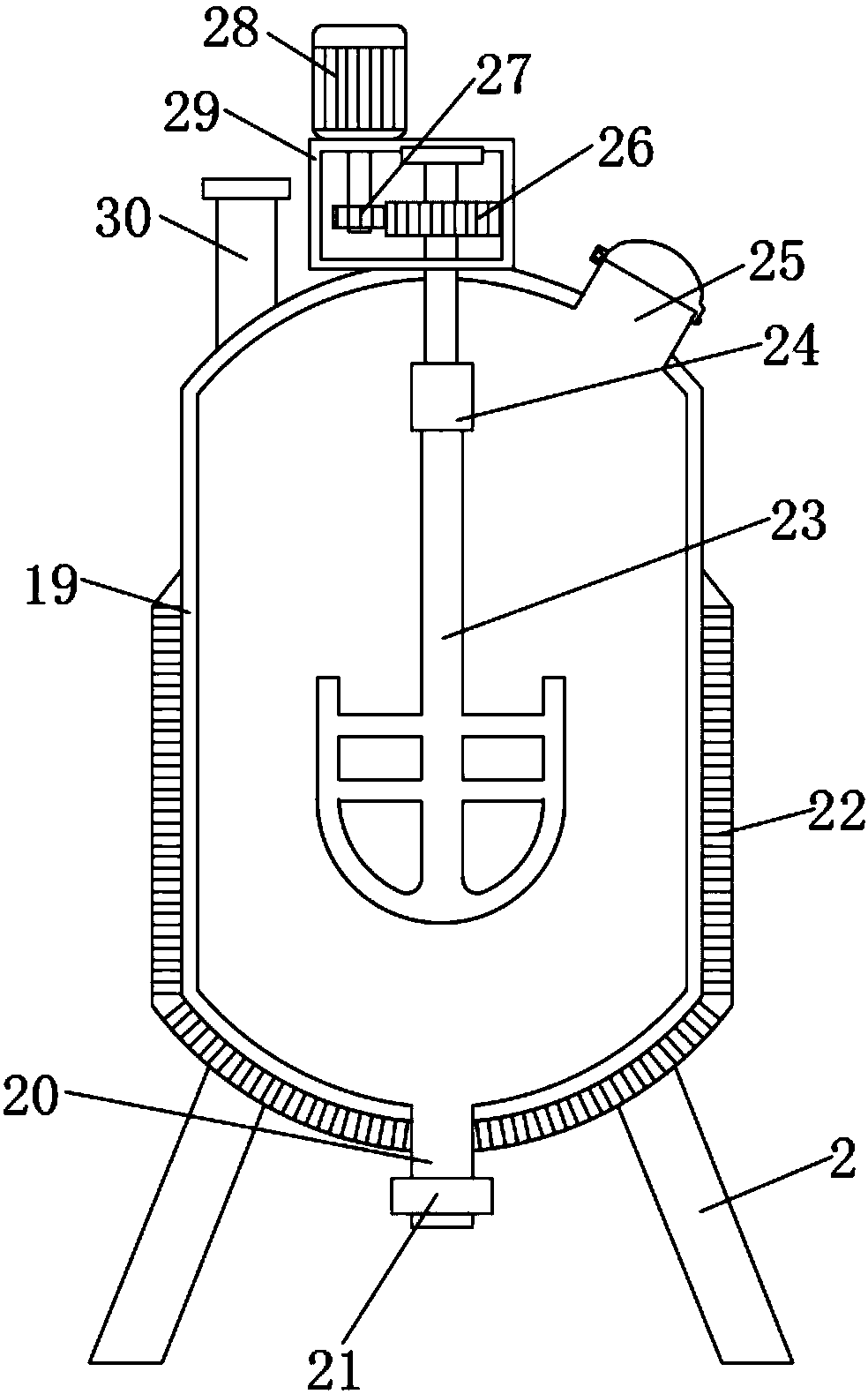

The invention discloses equipment for dewaxing and degreasing rice oil at the temperature of 0 DEG C. The equipment comprises a base, wherein two supports are symmetrically arranged on the base and are commonly provided with a heat exchanger; the heat exchanger is provided with a first feeding pipe, a second feeding pipe, a first discharging pipe and a second discharging pipe; the base is providedwith a first water pump; the first discharging pipe is connected with the first water pump by a first pipeline; the first water pump is provided with a crystallizing pipe; a plurality of groups of first supporting frames are arranged on the base at an equal distance and each group of first supporting frame is respectively and commonly provided with a dewaxing and crystallizing tank which is connected with the crystallizing pipe by a first branch pipe. The equipment disclosed by the invention has the beneficial effects that the structure is simple and the use is convenient; no any chemical substance is added in the process of cooling the rice oil to precipitate out crystal wax, so that the green and environment-friendly effects are achieved; the crystal wax precipitated out is more sufficient, and after filtration, the effect of degreasing the rice oil is achieved, so that the productivity of finished oil is increased to a certain extent, and the equipment is worthy of being promoted.

Description

technical field [0001] The invention relates to the technical field of rice oil production equipment, in particular to a 0-degree rice oil dewaxing and degreasing equipment. Background technique [0002] Rice oil contains 3%-5% wax and a certain amount of solid fat. The presence of wax and solid fat will reduce the transparency of the oil and affect the color of the oil under lower temperature conditions. At the same time, it will reduce the digestion and absorption rate, making it taste and palatability Deterioration, and then reduce the edible quality and nutritional value of oil. The traditional dewaxing and degreasing process of rice oil adopts the dewaxing of decolorized oil and degreasing of deodorized oil, that is, dewaxing first, then degreasing, two crystallization, crystal growth, and filtration processes. In the process of heat exchange and cooling, a large amount of cooling liquid and cooling water are wasted. The use of crystal aids and filter aids in the proce...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C11B3/00

CPCC11B3/001

Inventor 王伟

Owner 王伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com