Rice oil crystallizing device

A crystallization device, a technology of rice oil, applied in the direction of solution crystallization, heat exchange cooling crystallization, fat oil/fat refining, etc., can solve the problems of entraining oil, reducing the productivity of refined oil, wasting cooling liquid cooling water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

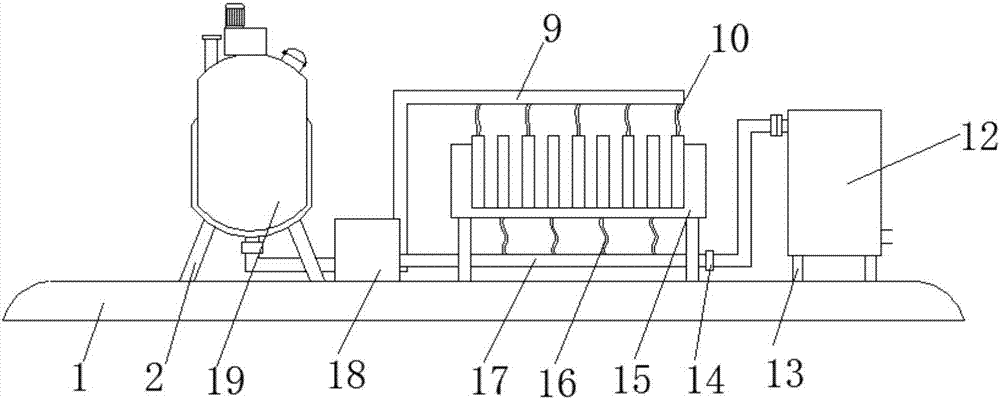

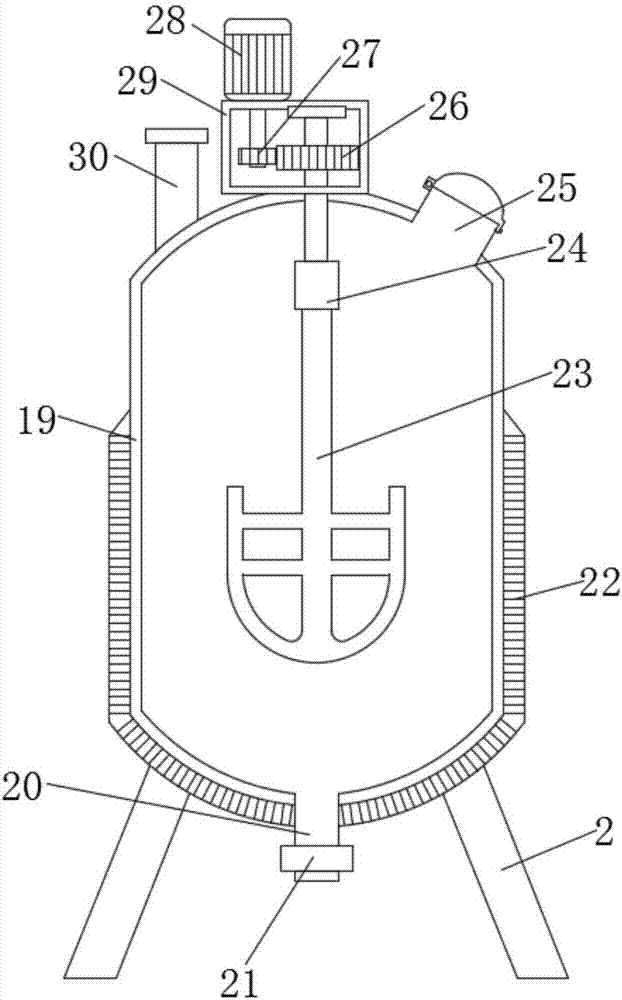

[0018] Embodiment 1: refer to Figure 1-2 , a rice oil crystallization device, comprising a base 1, two first support frames 2 are arranged on the base 1, a dewaxing crystallization tank 19 is arranged on the first support frame 2, and a heat exchange plate is arranged on the outer cover of the dewaxing crystallization tank 19 Pipe 22, the dewaxing crystallization tank 19 is provided with observation tube 25, and the observation tube 25 is rotatably connected with a cover, the dewaxing crystallization tank 19 is provided with the third feeding pipe 30, and the dewaxing crystallization tank 19 is fixedly connected with Reduction case body 29, reduction case body 29 is provided with servomotor 28, and the driving end of servo motor 28 runs through reduction case body 29 and is provided with the first gear 27, and the reduction case body 29 is provided with rotating shaft by needle roller bearing, and The lower end of the rotating shaft runs through the reduction box 29 and the d...

Embodiment 2

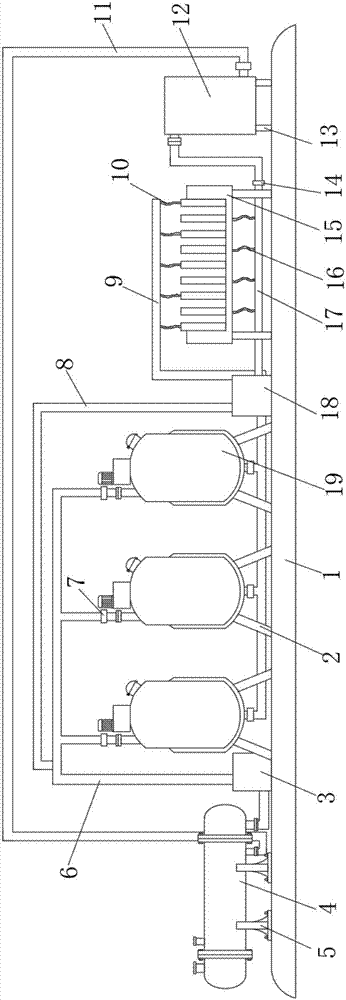

[0019] Embodiment 2: refer to Figure 2-4 , the present invention is applied to a kind of 0 degree rice oil dewaxing and degreasing equipment, comprising a base 1, two supports 5 are symmetrically arranged on the base 1, and a heat exchanger 4 is jointly arranged on the two supports 5, and the heat exchanger 4 is provided with the first feed pipe 37, the second feed pipe 34, the first discharge pipe 33 and the second discharge pipe 38, the two supports 5 are provided with a tank body 39, and the tank body 39 is provided with There is a second feed pipe 34 and a second discharge pipe 38. Both ends of the tank body 39 are fixedly connected with a tube plate 31, and a plurality of connection holes are evenly opened on the tube plate 31, and each tube plate 31 passes through The locking screw is connected with a tube box 36, and a heat transfer tube 32 is arranged between the two tube sheets 31, and the heat transfer tube 32 communicates with the connecting hole. One of the tube b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com