Rice bran fatty oil storing adding equipment used in forage production

A technology for adding equipment and rice bran fat, applied in the field of rice bran fat oil storage and adding equipment, can solve the problems of oil pipeline blockage, poor fluidity, easy solidification, etc., and achieves the effects of prolonging the storage period, simple structure and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

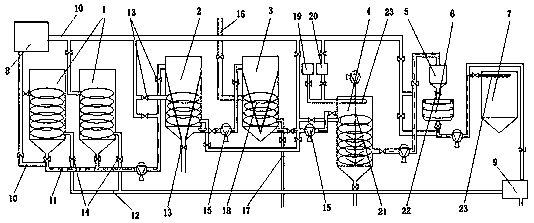

Method used

Image

Examples

Embodiment 1

[0034] Embodiment one of the present invention: adopt the dewaxed coarse cloth to be set in the filter basket 27 to process:

[0035]

Embodiment 2

[0036] Embodiment 2 of the present invention: there is no mark in the accompanying drawings, no filter basket 27 is provided in the dewaxing tank 3, but a plate and frame filter is used for filtering and dewaxing;

[0037] Plate and frame filter is a stainless steel multi-layer plate and frame filter press, which is suitable for closed filtration of liquids with a concentration below 50% and low viscosity and less slag content to achieve purification, sterilization, clarification, etc. Requirements for fine filtration and semi-fine filtration.

[0038] Its structure is: the filtration part is composed of ten layers of filter plates, the filtration area is large, and the flow rate is large; and according to the requirements of different production processes (primary filtration, semi-fine filtration, fine filtration) of the filtered solution, different filter membranes can be replaced, and According to the size of the user's production flow, the number of filter plate layers can...

Embodiment 3

[0042] When using a filter to cool down, a three-step cooling method can also be used: the cooling rate of the first stage is 4-5°C / h, and when the temperature drops below 70°C, it enters the second stage, and the cooling rate of the second stage is 2-3°C / h h, enter the third stage when the temperature drops below 50°C, the cooling rate of the third stage is 1-2°C / h, keep stirring for 2-4 hours when the temperature drops below 15°C, and then filter to remove wax through a plate and frame filter , to obtain dewaxed rice bran fat oil;

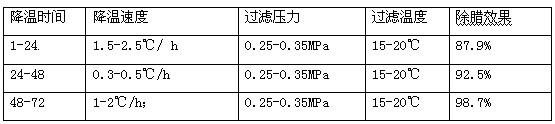

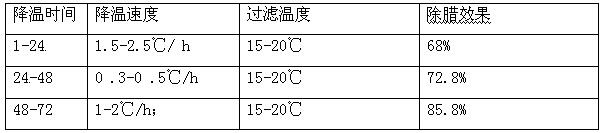

[0043] Carry out dewaxing treatment by above-mentioned dewaxing tank 3, the wax content in the oil plant that comes out in the dewaxing tank 3 outlets of the present invention reduces about 50-85.8% than original rice bran fat oil, if adopt filter machine to carry out dewaxing treatment, comparable to the original Rice bran fat oil was reduced by 87.9-98.7%.

[0044] Further, the alkali refining desoaping tank 4 is also provided with an electric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com